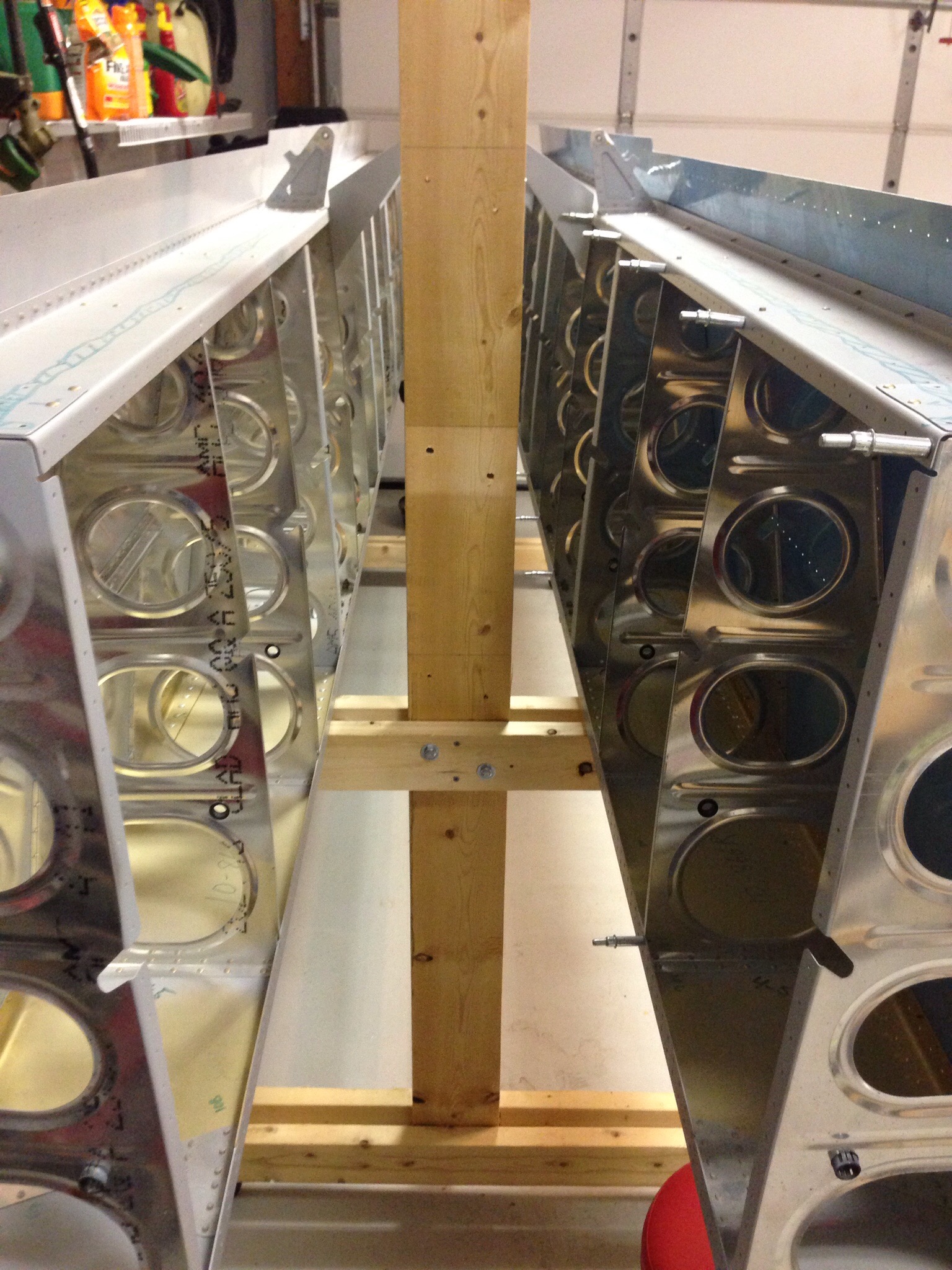

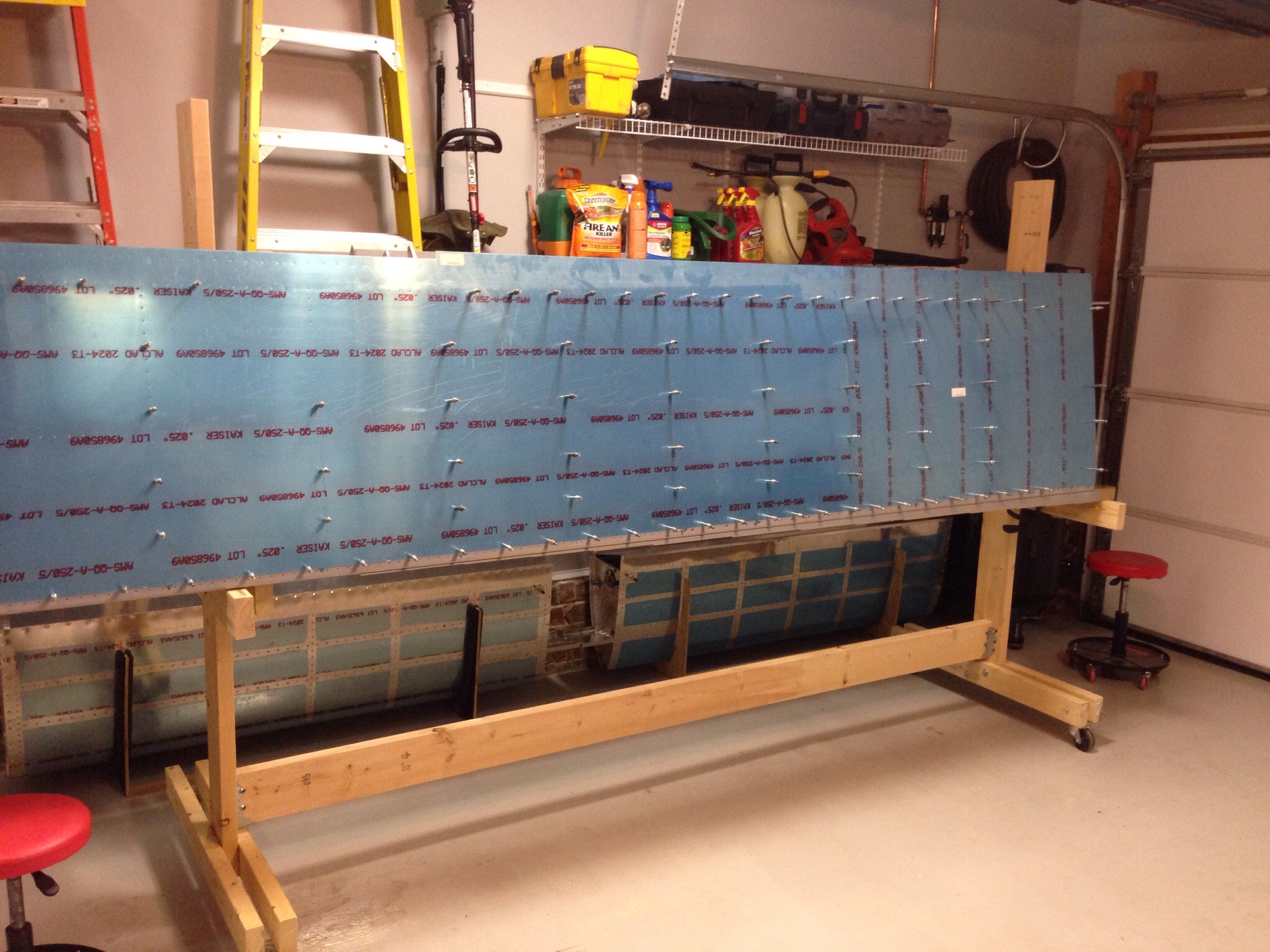

While both fuel tanks cure, I shifted my focus back to the wings. The first problem I wanted to solve was my wing rack. While it’s a nice storage solution to keep the wings safe and out of the way, I quickly saw that it was keeping the spars in a warped state due to the way it was hanging. So I disassembled the frame and decided to shorten it, allowing the spars to sit on top of two cross pieces. This would allow me to better square the wing and secure it a little better while putting it in a better position to work on it. I’m much happier with the result now, as it’s more of a work platform and a storage solution. I’ll also be able to store the wings on it with the leading edges attached with few modifications.

Then, I completed my wing-walk through. The wing kit was purchased used by me, and being the second builder, I wanted to first understand all the work that went into them and to ensure the work was done correctly and completely. Overall the wings look very good (as I knew at the time of purchase) but there were a few action items.

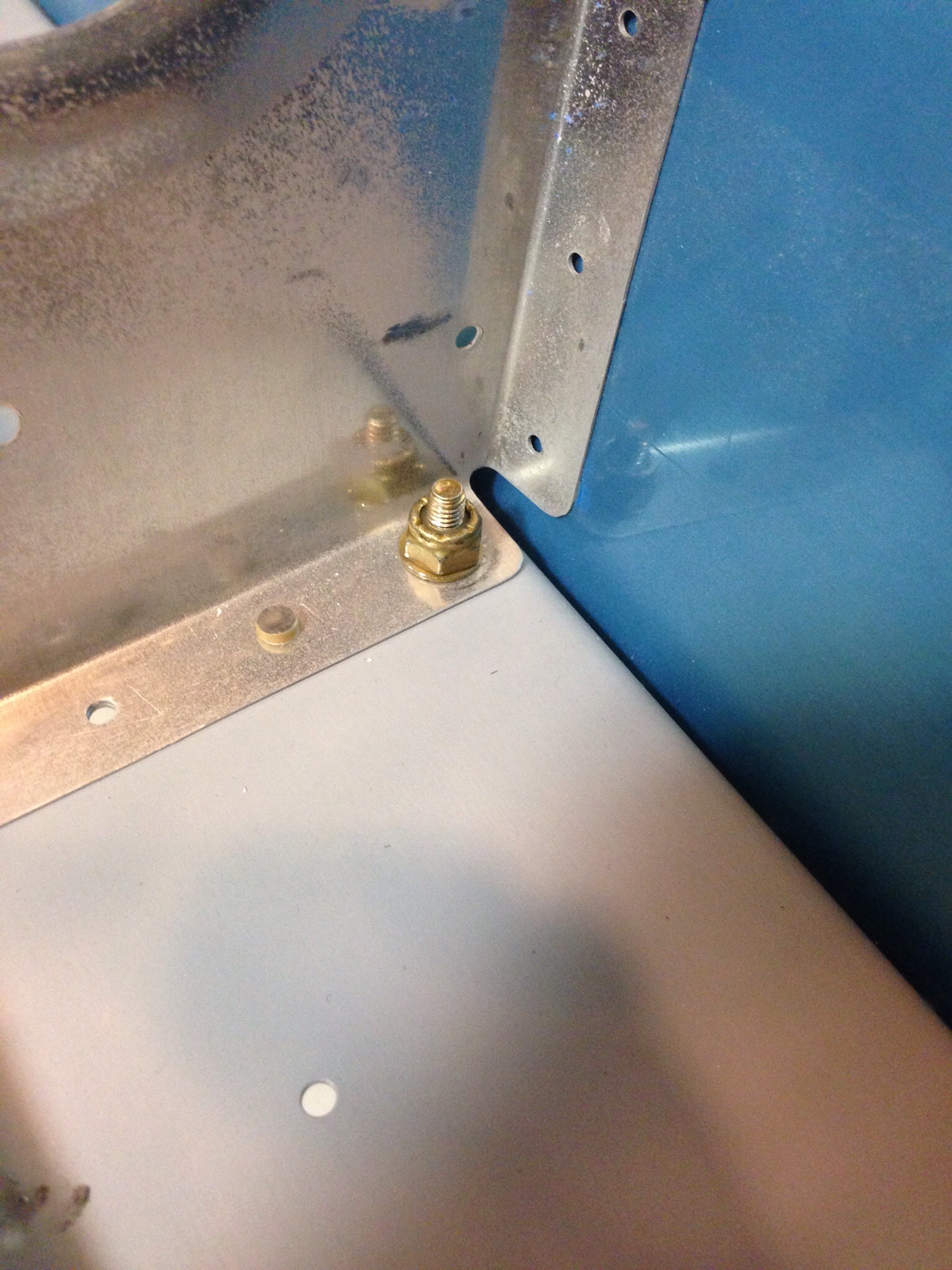

There were about six places on the rib-rear spar intersections that had pop rivets instead of the usual AN round head solid rivets. I still don’t understand why, as it was random and only one per rib. So I drilled those out, cleaned up the holes and installed the rivets according to plans. I had only one hole that was really buggered up, where I couldn’t get any rivet to hold.

A quick email to Van’s said to drill it out and replace with an AN3 bolt and locknut. It was a simple fix and I know it’s all done right now. Every step was checked off on the plans and it is up to speed for me to take over.