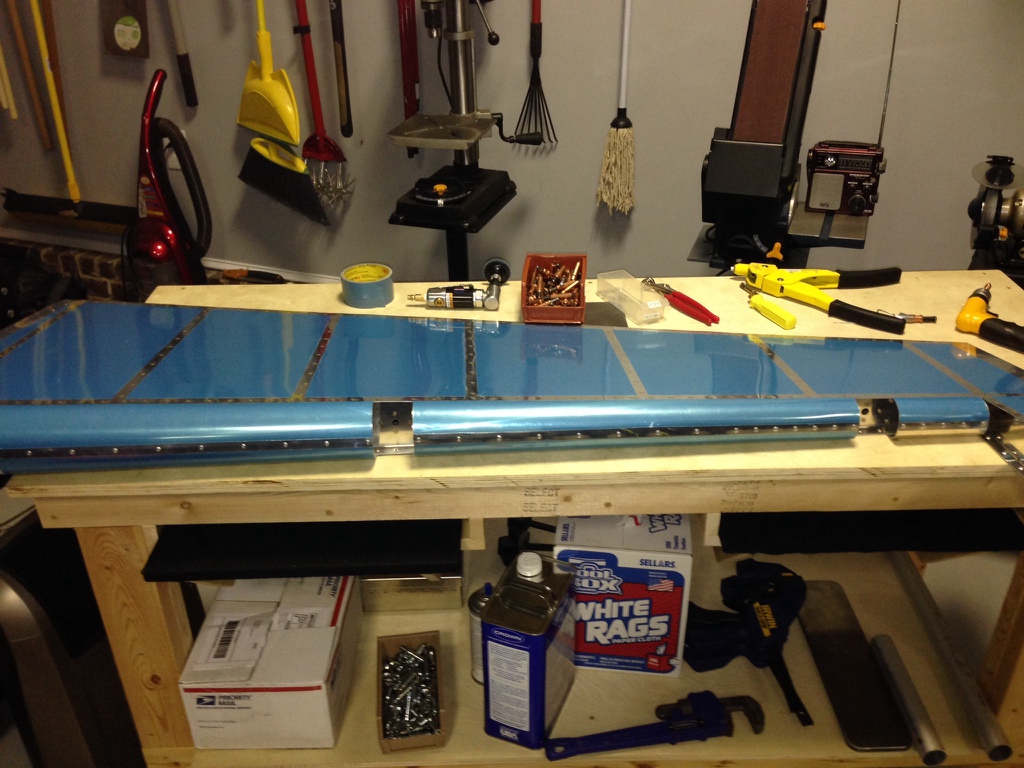

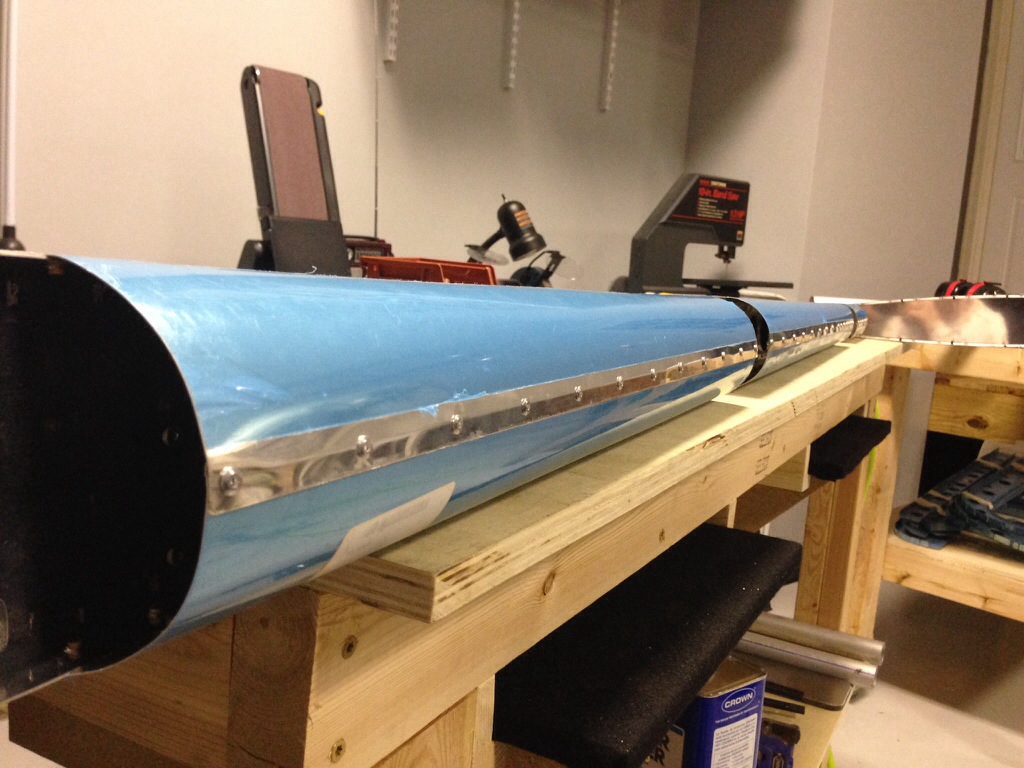

I spent tonight rolling the leading edges for the rudder. Didn’t I say to roll the edges before final assembly? Yes, I did. I’ll have to remember that next time! The process really isn’t too bad. I use duct tape and an aluminum pipe cut down to just longer than the section of skin (I have three different lengths that work well). Once I have it rolled, I use an edge roller to bend both skins inward. I find bending both vs just the top as the plans call for, helps the skins sit flatter once together. Putting them together the first time is the hard part, but is manageable for one person but easier with two. Once clecoed, final drill then uncleco to deburr. Then back together and finish off with the pop rivets.

Despite putting good bends and slight pressure on the rivet tool when setting them, I have a few that still show a space between the skins. I’m thinking about ordering some extra rivets to redo those few and see if I can get a better result. But, overall I’m happy with it.

One thing I continue to be proud of is keeping the shop clean. I replace tools after I use them and be sure everything is put up before calling it quits for the night. Not only does it keep the garage looking good, it keeps me organized and let’s me work a lot faster not having to sift through junk to find what I need.