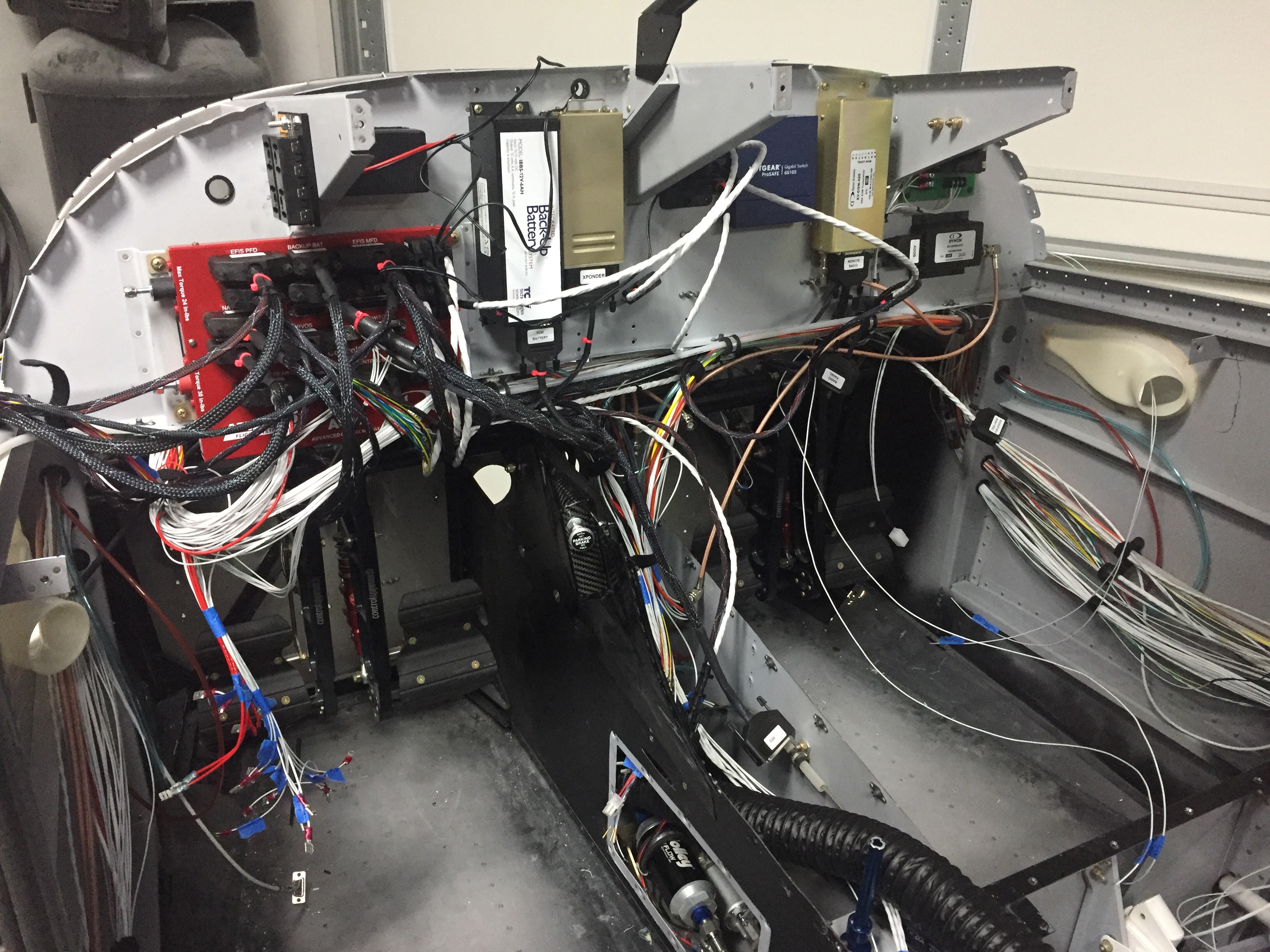

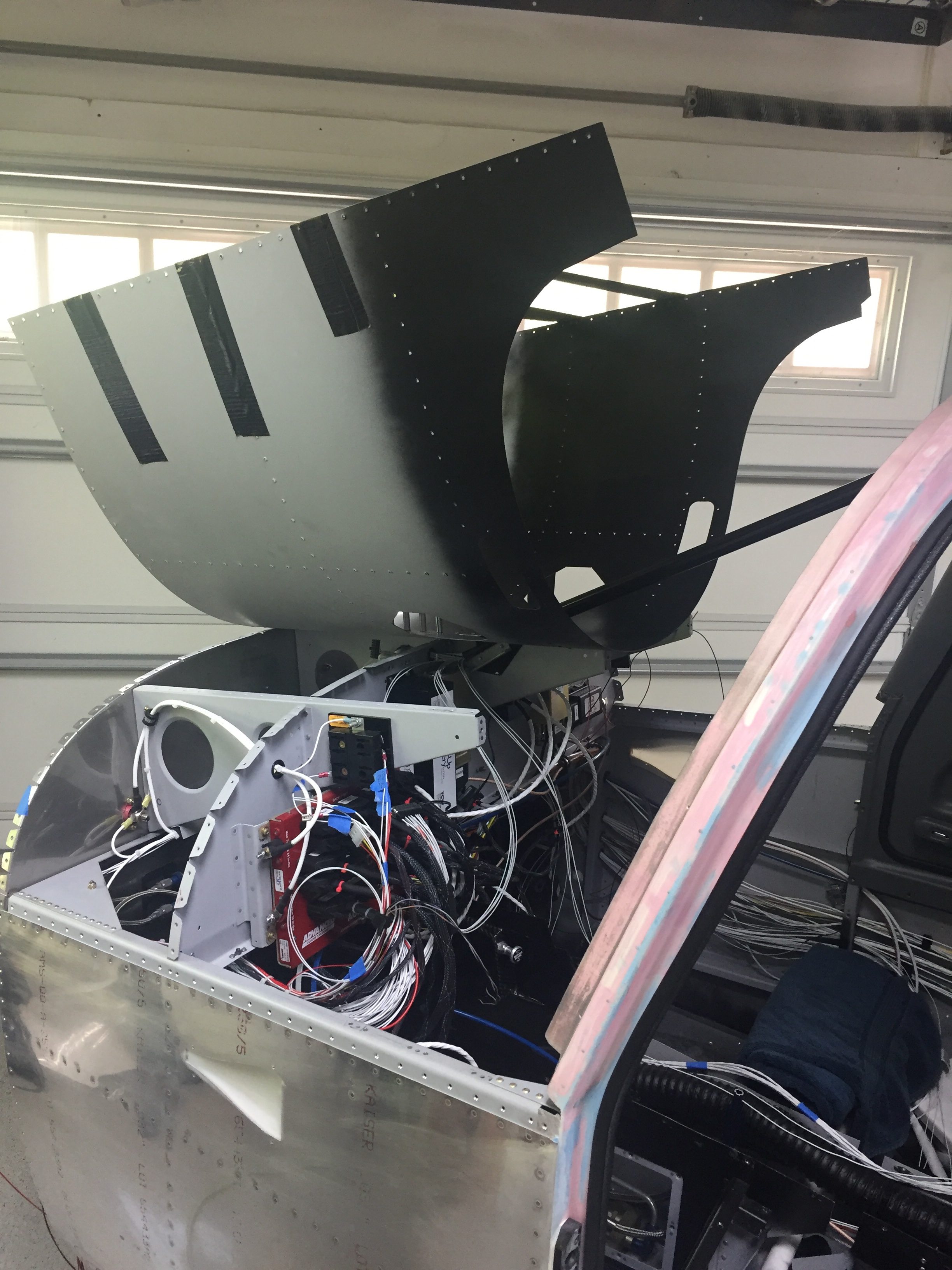

At this point, I’m out of wires to run in the plane and about out of wire from my workbench! I made the call to rivet in the forward fuselage section structure so that the bundles could be zip-tied and I could move forward with putting the panel and avionics in for good. (I actually riveted this in before doing the firewall insulation, but it was easier to type in this order.) As with most big things, it was very anti-climactic and completed in about 15 minutes.

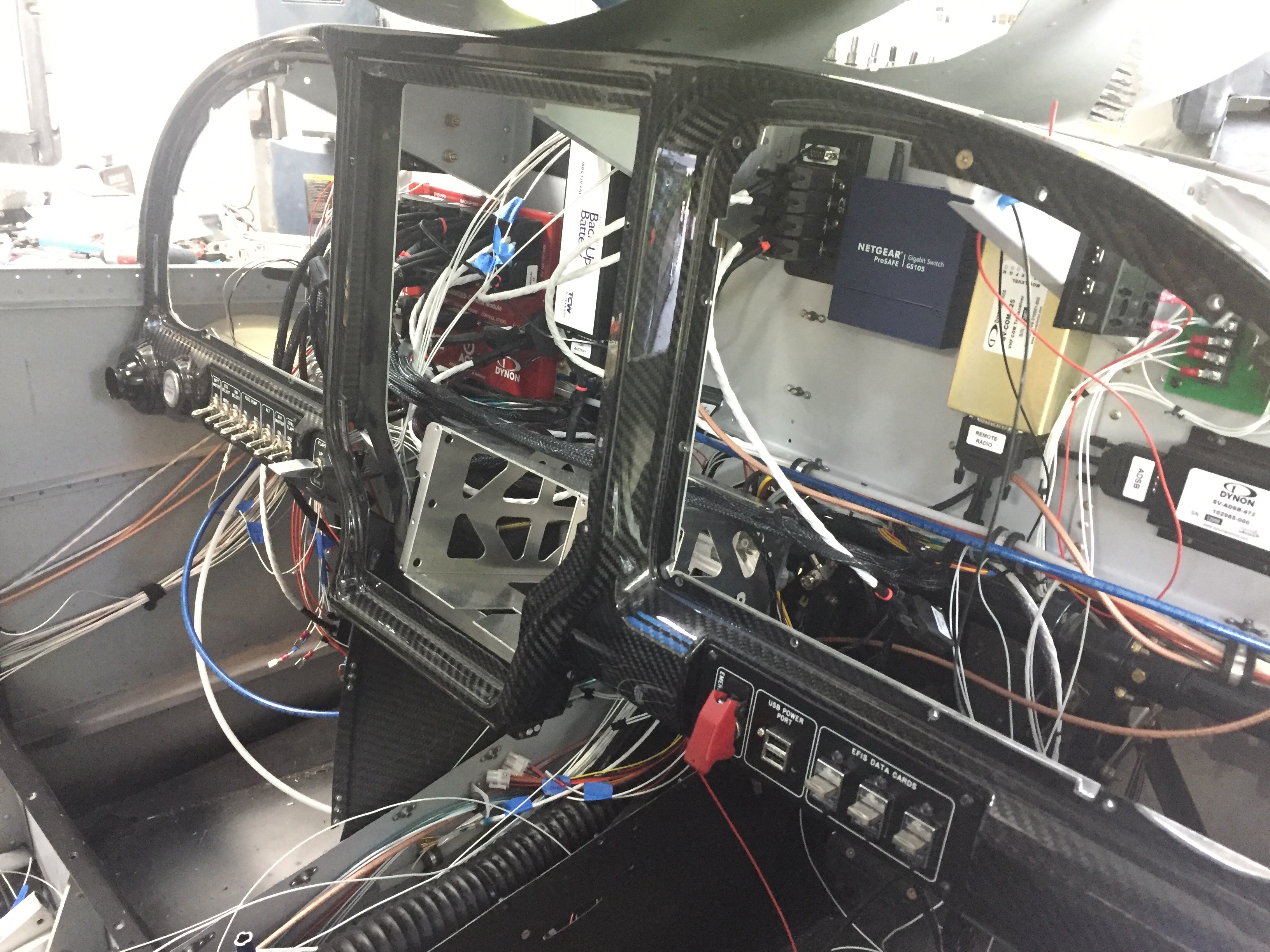

I put the carbon fiber frame and back plate in and got it all screwed together in the right order. All of the switch panels were hooked up for good and along the way, bundles were tidied up as much as possible.

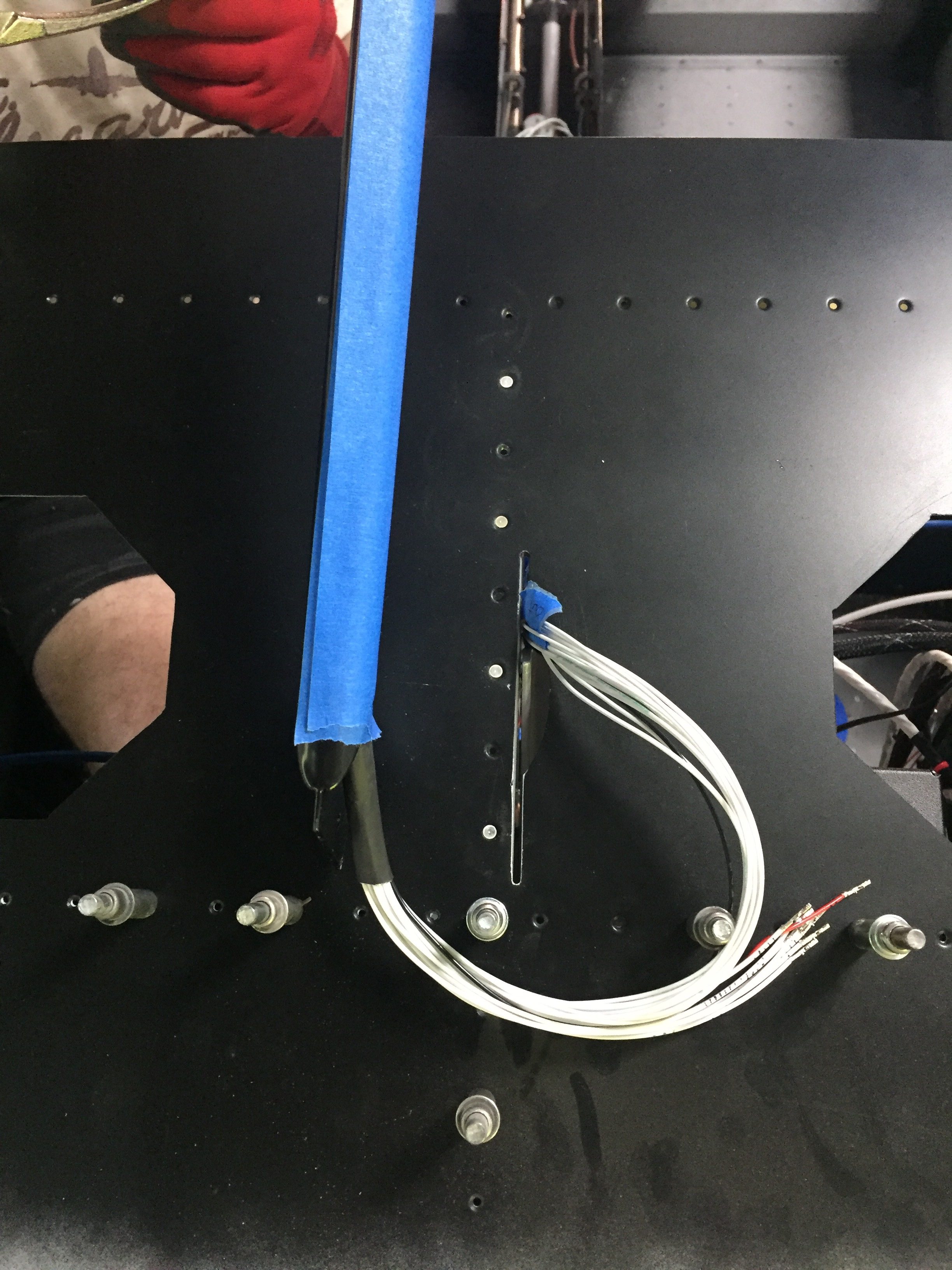

The last major task for wiring was the overhead console and lighting wire run. The front structure (now in) and skin has to be installed before I can run the wires down the support bar (powder coated black with the engine mount). I wanted to keep as much access open as I could to finish up the avionics so I worked out a way to bend the skin upwards by riveting the center rivet line only. Laura came out to work her magic behind the rivet gun and assisted in getting the wires through the bar and the bar installed. It was a bit tricky feeding everything through the skin but worked out well in the end. I did elongate the slot in the skin since my overhead switch panel prevents the bar from going in at the bottom first.

I set about connecting the wires from the overhead since I had already pre-routed them and installed terminals as needed since access would be difficult once the forward skin is in place. Glad I did that, because I could never have pinned them out as they were after the skin and bar were installed. The back lighting wires were all solder sleeved together to the power supply and the positive wires for the power supply, start switch, and O2 controller back lighting were all ran to the dimmer. After a lot of observing and double checking, the only wires left unterminated are those going to the EMS/ECUs (I won’t have the ECUs until July) so nothing left other than starting to test stuff out!

The lighting control module (LCM) and instrument back lighting will be on the always hot bus so I was able to hook my bench power supply up to test it. I was pretty nervous as there are a lot of complicated wires on the LCM and I was afraid of knowing where or how to troubleshoot an issue. I shut the doors, turned on power and held my breath. Opening the door should have turned all the lights on but it just made them flash. The foot well dimmer was hooked up to the overhead and the back lighting didn’t work at all. Fan-f**king-tastic. Great start, Tim.

My skills at troubleshooting are more advanced than my confidence, and I was able to correct the wiring on the dimmer module (I had mislabeled the potentiometers) and figure out the back light power supply had a solder sleeve that didn’t solder all the way causing a bad connection. Those were corrected and I had two out of three working. The back lighting looks magical (yes, I said magical) and I sat in the dark for five minutes ooohing and ahhhing at myself. The overhead dimmer and foot well dimmer circuits were now working and I could see how well Sean’s (Plane Around) LEDs illuminate the cabin. The door lights and switches were still not working, though. As soon as the door opens, I could hear the relay click causing the lights to turn off. It turns out I had added an extra ground to the override switch and it was immediately overriding the timer in the LCM. I corrected that and at the end of the evening got to see the fruits of my labor on the LCM as everything worked exactly like it should!

It’s finally time to slide all of the pretty glass screens in place and see what it looks like all fired up. The cutouts on the panel inserts are exactly the size needed, so clearance was a bit tight. Pretty soon, I had all three screens in place along with the IFD slid into the tray. The G5 was installed and I hooked up the last two fittings for the pitot static system and got the tubes plugged in. The PFD was a tight fit and required several attempts and getting all the wire bundles situated just right on the ACM to allow the connectors from the screen to fit without crimping.

Man, does this panel look awesome!! I have spent literally years designing the layout and dreaming about this very moment. I couldn’t be happier with the way it turned out. I’m really looking forward to sitting behind it and having great adventures with a massively capable avionics suite that is just as suitable for fun VFR flights as it is hard IMC. The carbon is a great look, the overlays are perfect, everything is in reach, and it is a real show stopper!

I also hooked up the lower console panel back lighting just to see how it works but won’t get the rest of the components connected until after power is applied. That is the next big step, so stay tuned!