Well, I enlisted some help. My dad came in for a couple weeks to visit and I

was quick to put him to work. I managed to get all the rivets in on the

bottom skin without having to drill out more than a handful. It’s a lot

different riveting now that you can’t easily check the shop head of the rivets

easily. I have gotten much better at “feeling” them go in and knowing when

enough is enough.

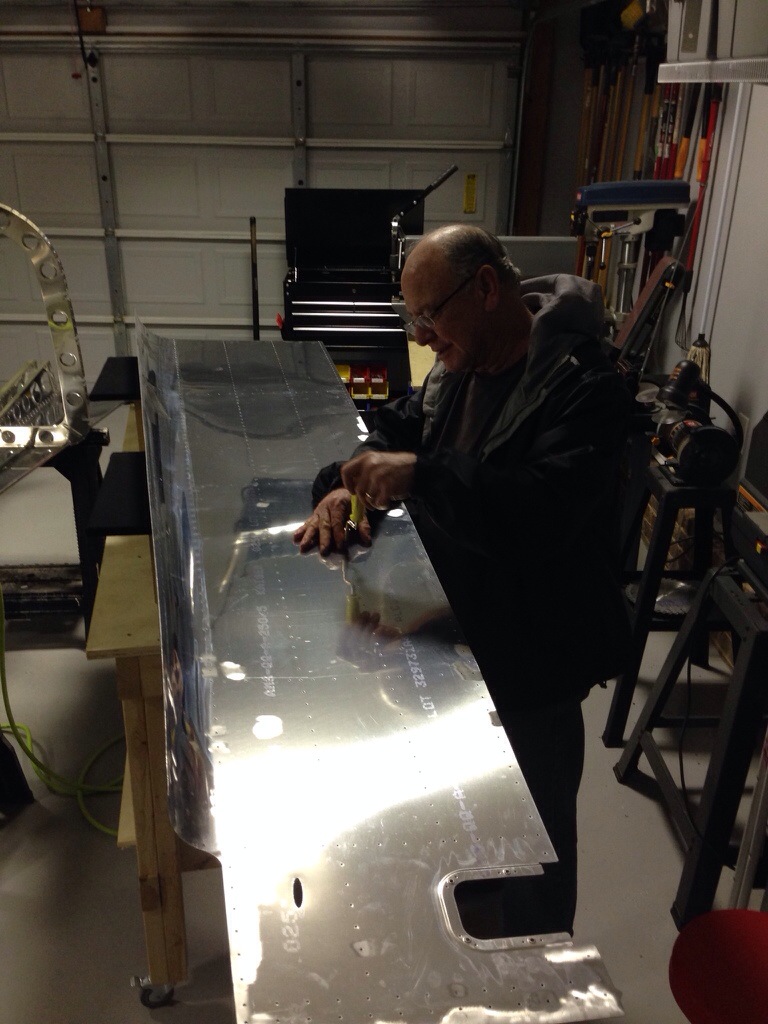

Dad helped me deburr the right side skin after I trimmed off the triangle

according to plans. While he was finishing up, I hit a few more surface

corrosion spots (typical of this kit as old as it is I guess) and spot primed

them. I then got ambitious and put an extra bur cutter into my power drill

and started experimenting. Long story short, I went to Lowes the next day and bought a small, handheld cordless screwdriver and ordered a hex adapter from Avery Tools. It’s so much faster and easier than having to spin the manual driver and with the lighter tool, I’m expecting less fatigue and sore wrists the next day.