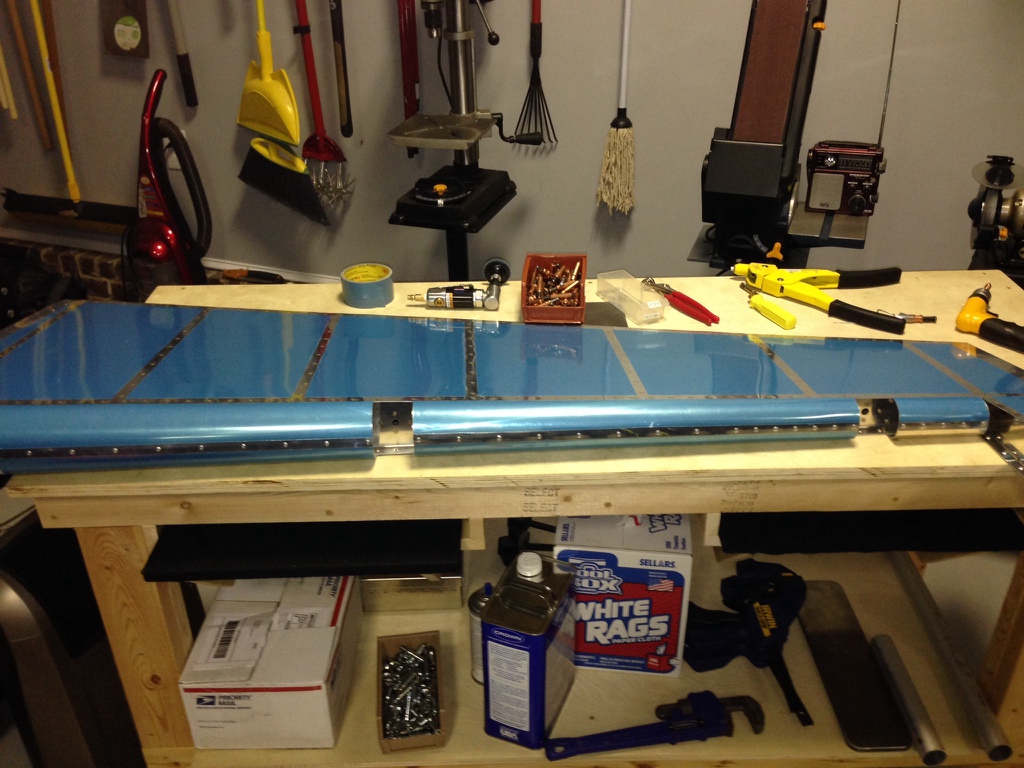

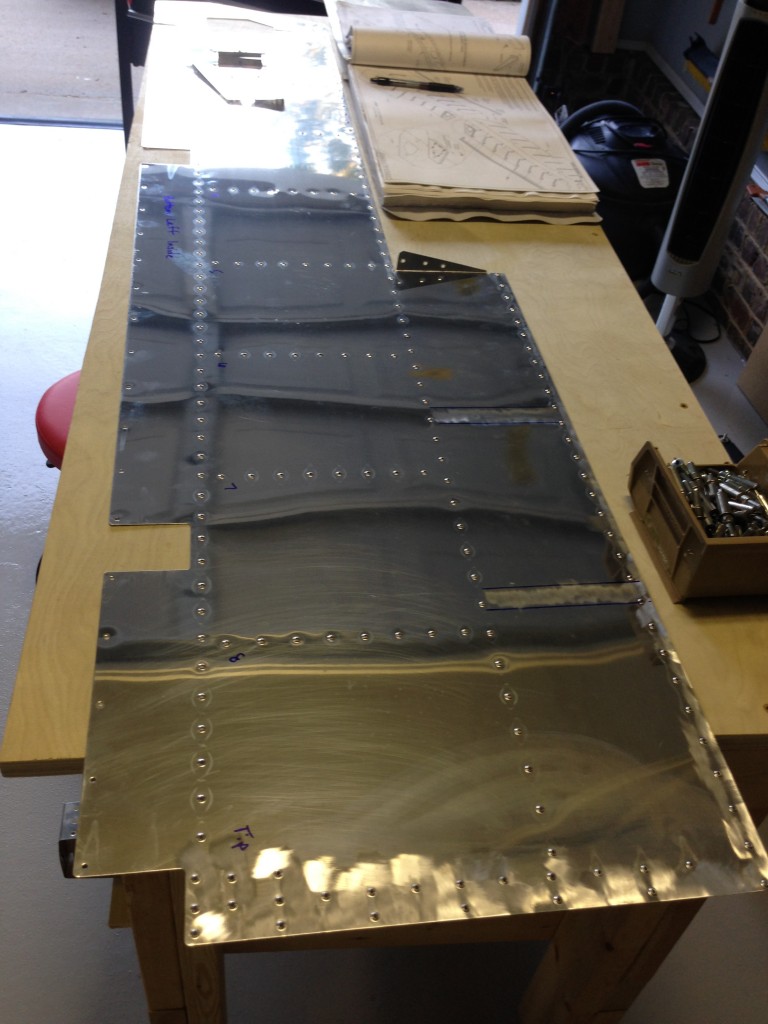

Good thing too, because this project has a lot of them! I finished deburring and dimpling the right elevator skin. Deburring takes forever it seems and is made more difficult with the shiny skin. I can see why folks leave the film on as long as possible (for scratch resistance as well). I also buffed out a couple of spots of surface corrosion I had on the skins and a few scratches on the spars. I’m using the Dupli-color self etching primer to spot prime those spots. Without going off on a tangent, I’ve researched and read on priming til I’m cross eyed and I am choosing not to prime unless specified by the plans or a condition such as imperfections in the metal.

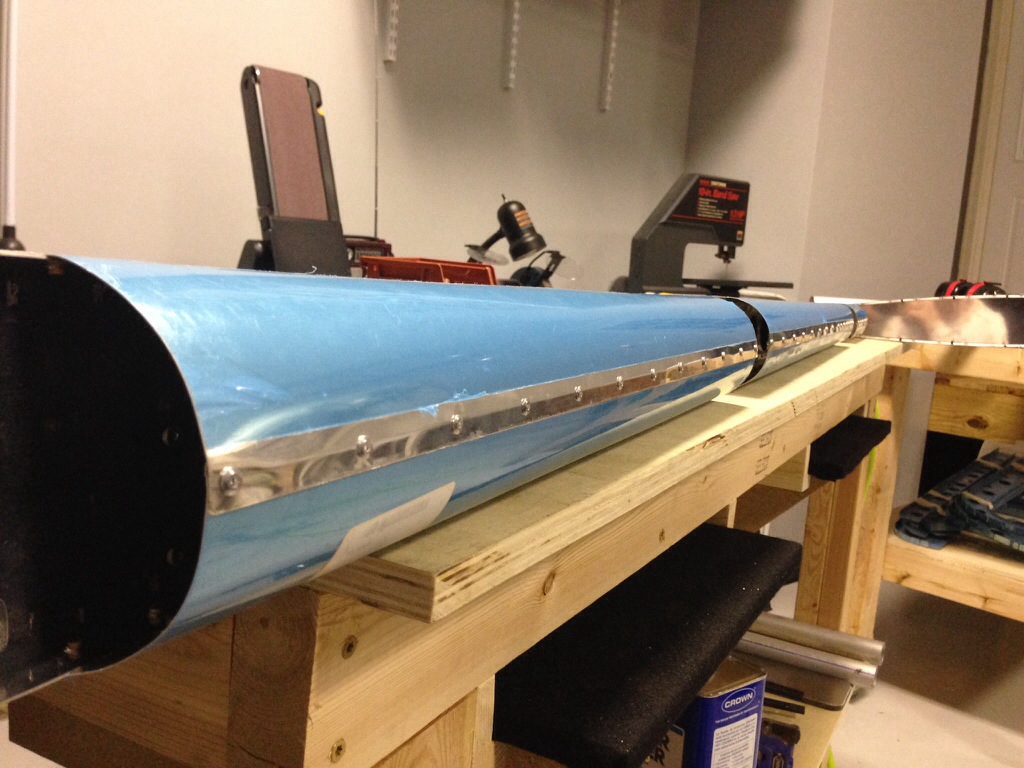

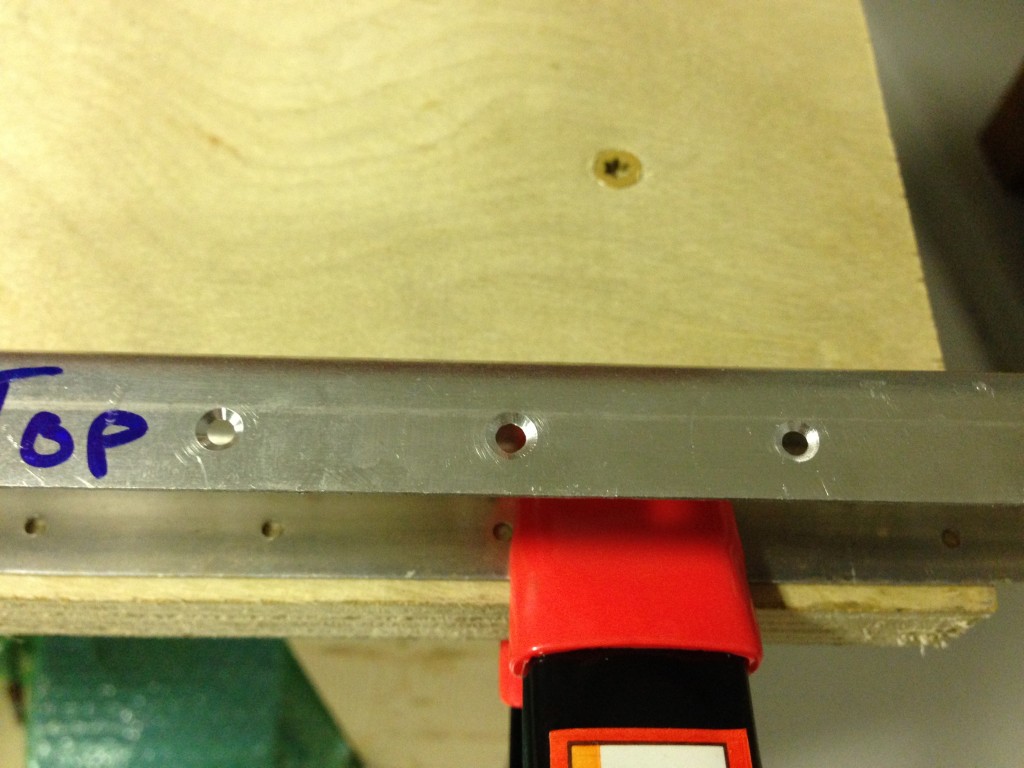

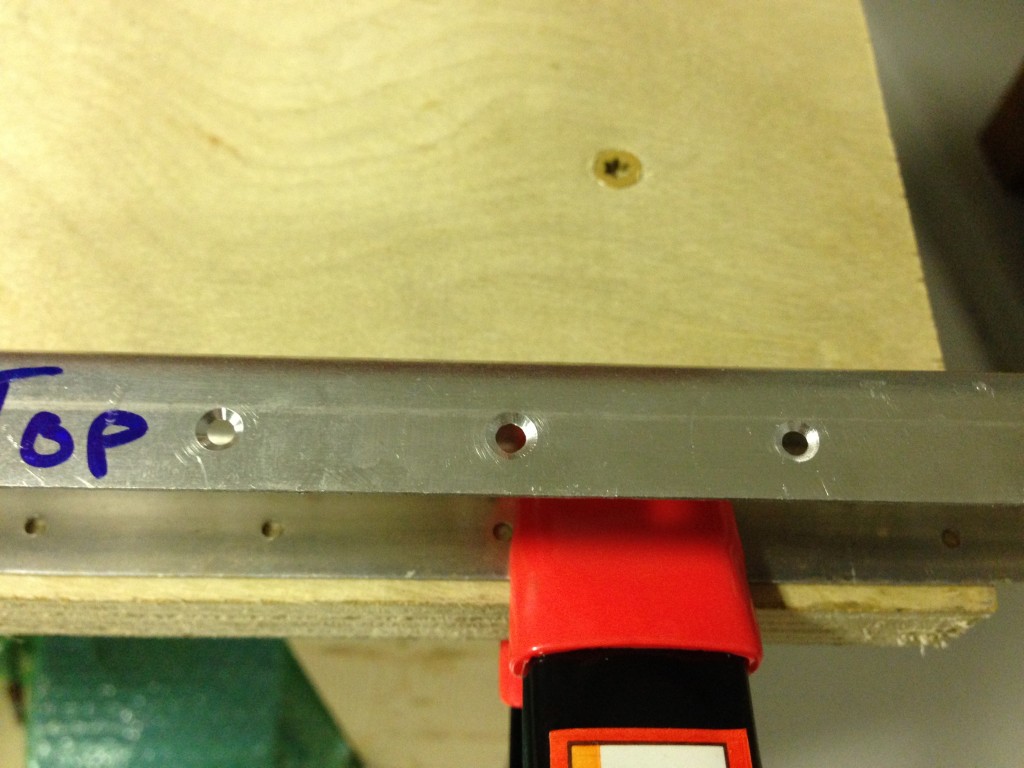

I ensured all the ribs are labeled and disassembled everything to prepare for riveting next. The spar needed to be countersunk on certain holes to allow a flat surface for the trim hinge to mount, so I got to use a tool for the first time! The countersink bit is really neat, but I expericenced some chatter on it so I may need to play with the speed, as it didn’t clean metal chips away quickly at 90 PSI.

I ensured all the ribs are labeled and disassembled everything to prepare for riveting next. The spar needed to be countersunk on certain holes to allow a flat surface for the trim hinge to mount, so I got to use a tool for the first time! The countersink bit is really neat, but I expericenced some chatter on it so I may need to play with the speed, as it didn’t clean metal chips away quickly at 90 PSI.

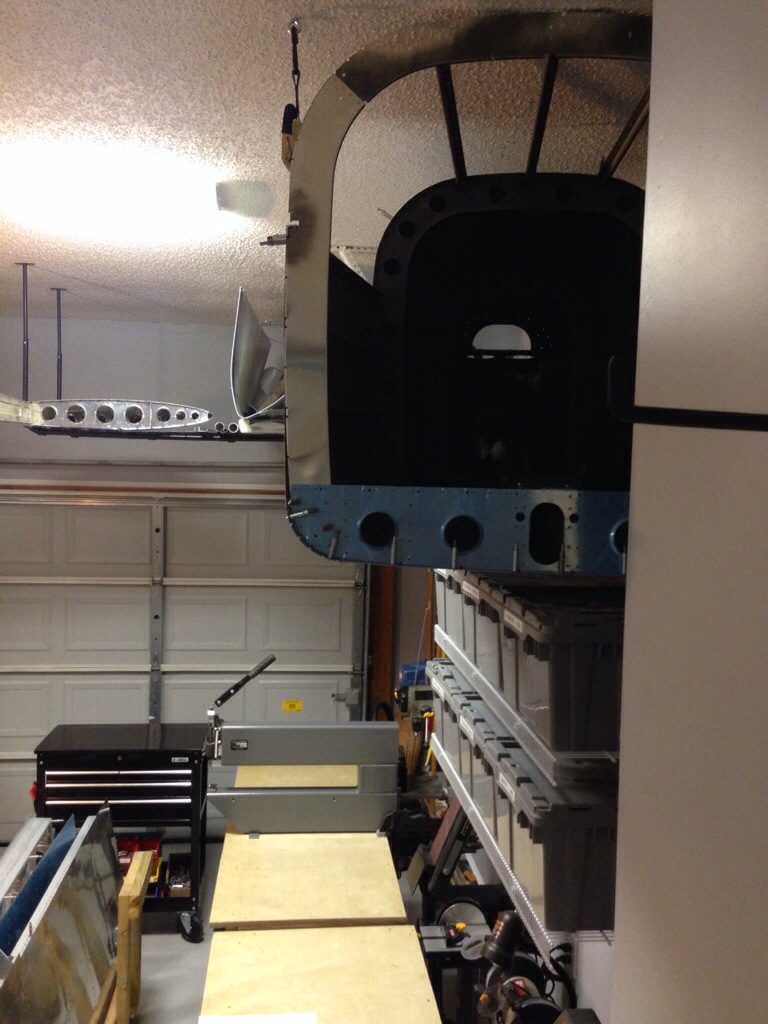

Finally, I picked up some inexpensive L brackets for shelving from Lowe’s and mounted them above my workbench to store the HS on. It has been sitting on the floor and my lovely wife has been very vigilant to ensure nothing hits them as she parks about a foot and a half away every night! Now they are safe and secure and most importantly out of the way until needed down the road.

Finally, I picked up some inexpensive L brackets for shelving from Lowe’s and mounted them above my workbench to store the HS on. It has been sitting on the floor and my lovely wife has been very vigilant to ensure nothing hits them as she parks about a foot and a half away every night! Now they are safe and secure and most importantly out of the way until needed down the road.

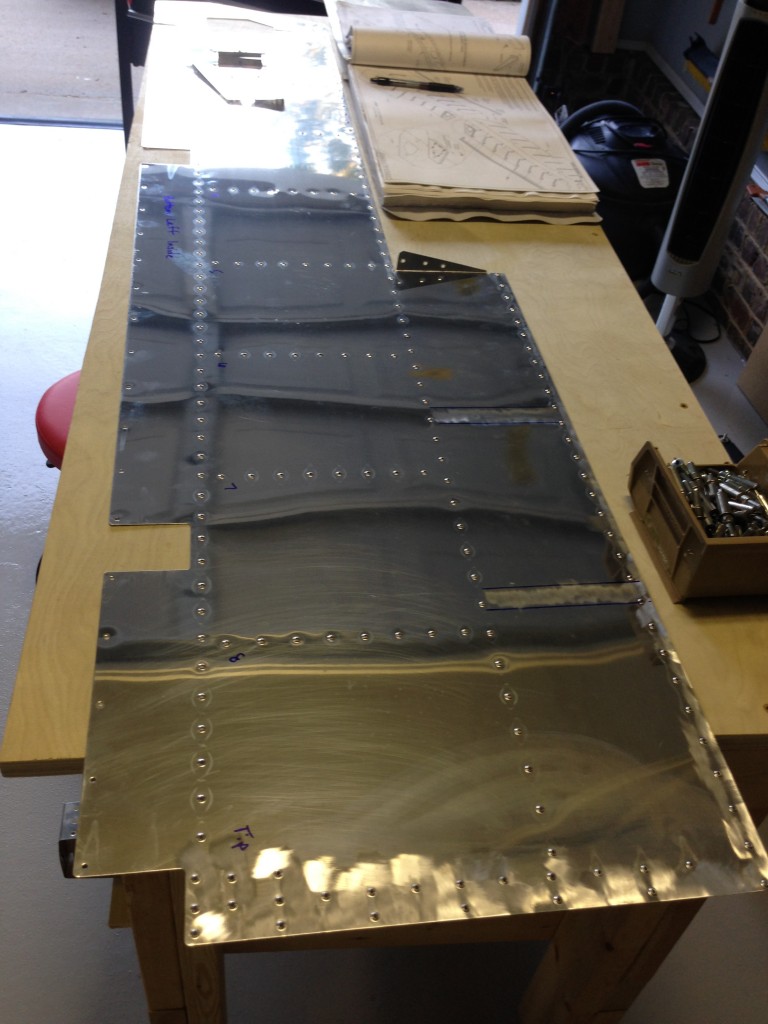

I also organized the pegboard a bit more than pictured, hung up the parts bins and just straightened up the work space. I’m finding it even more critical to keep the garage clean and tools in their places so I can work efficiently!