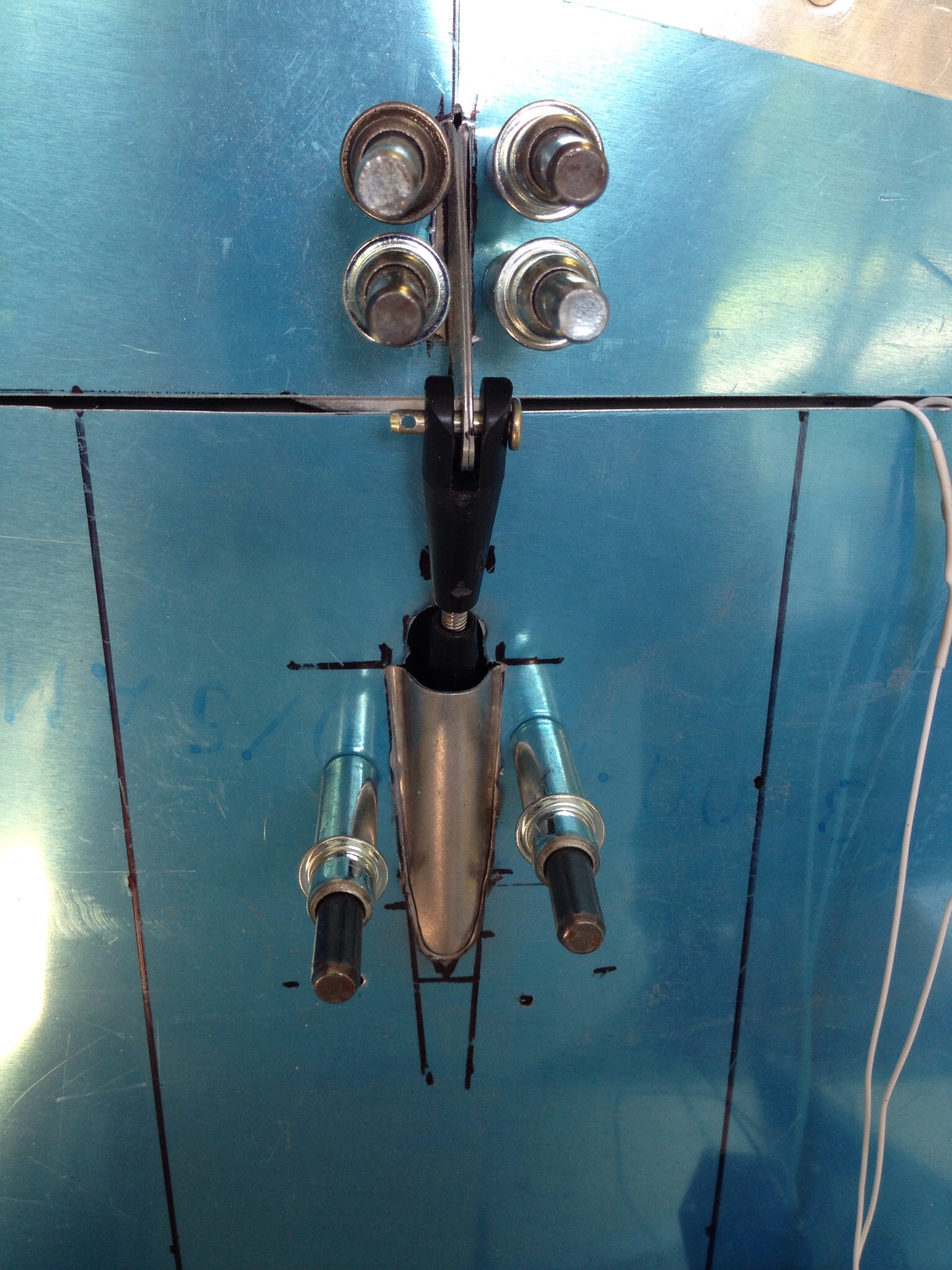

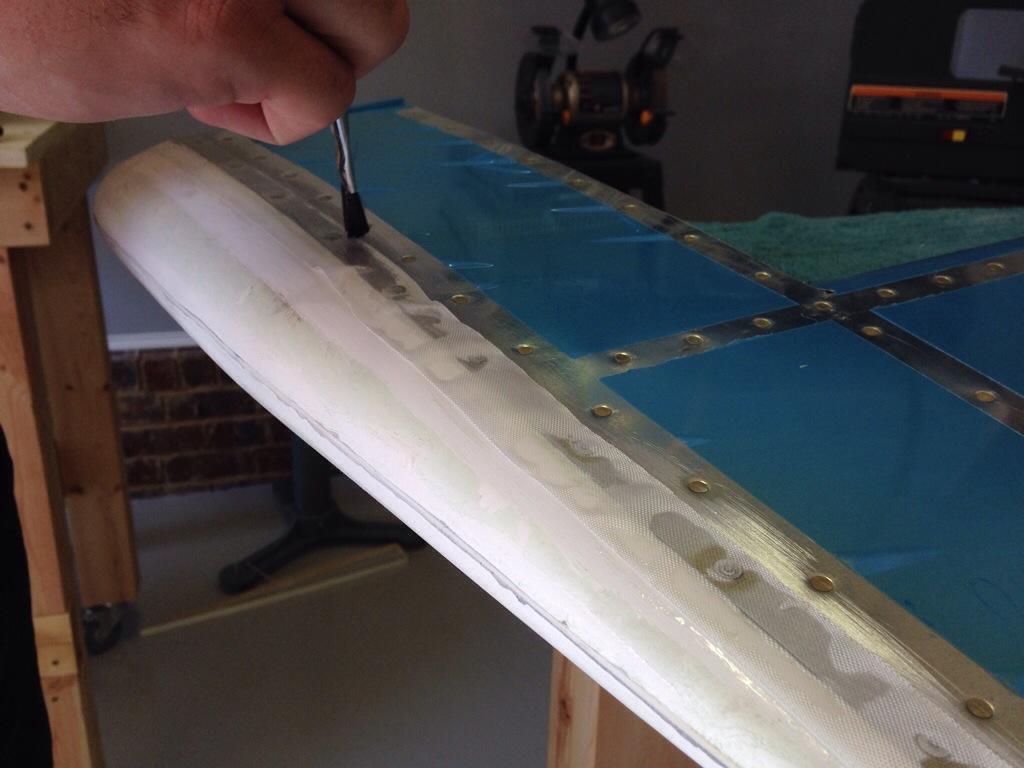

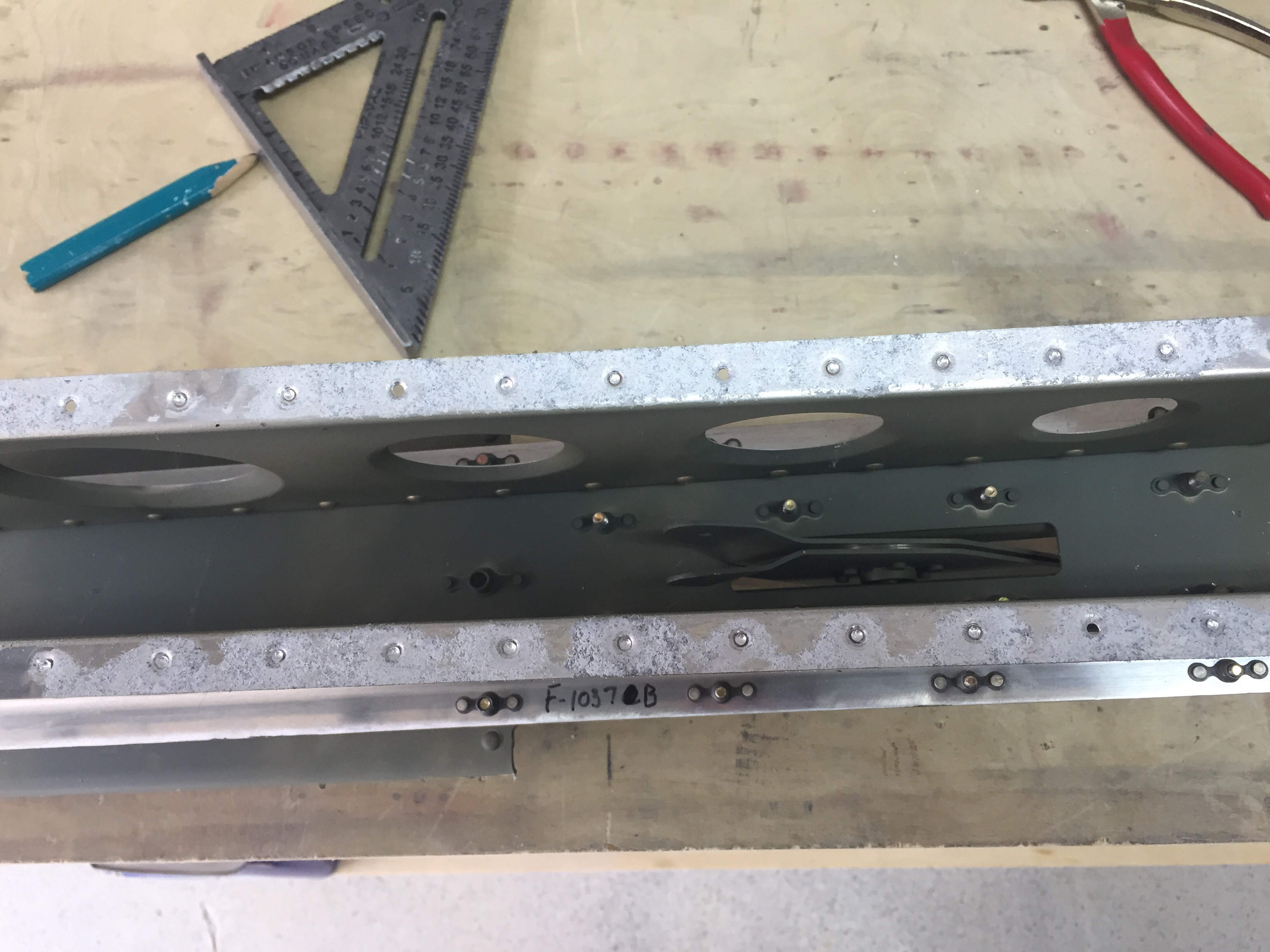

After drilling out all the rivets and removing the two ribs with feared corrosion, my suspicions were confirmed with a somewhat scary sight.

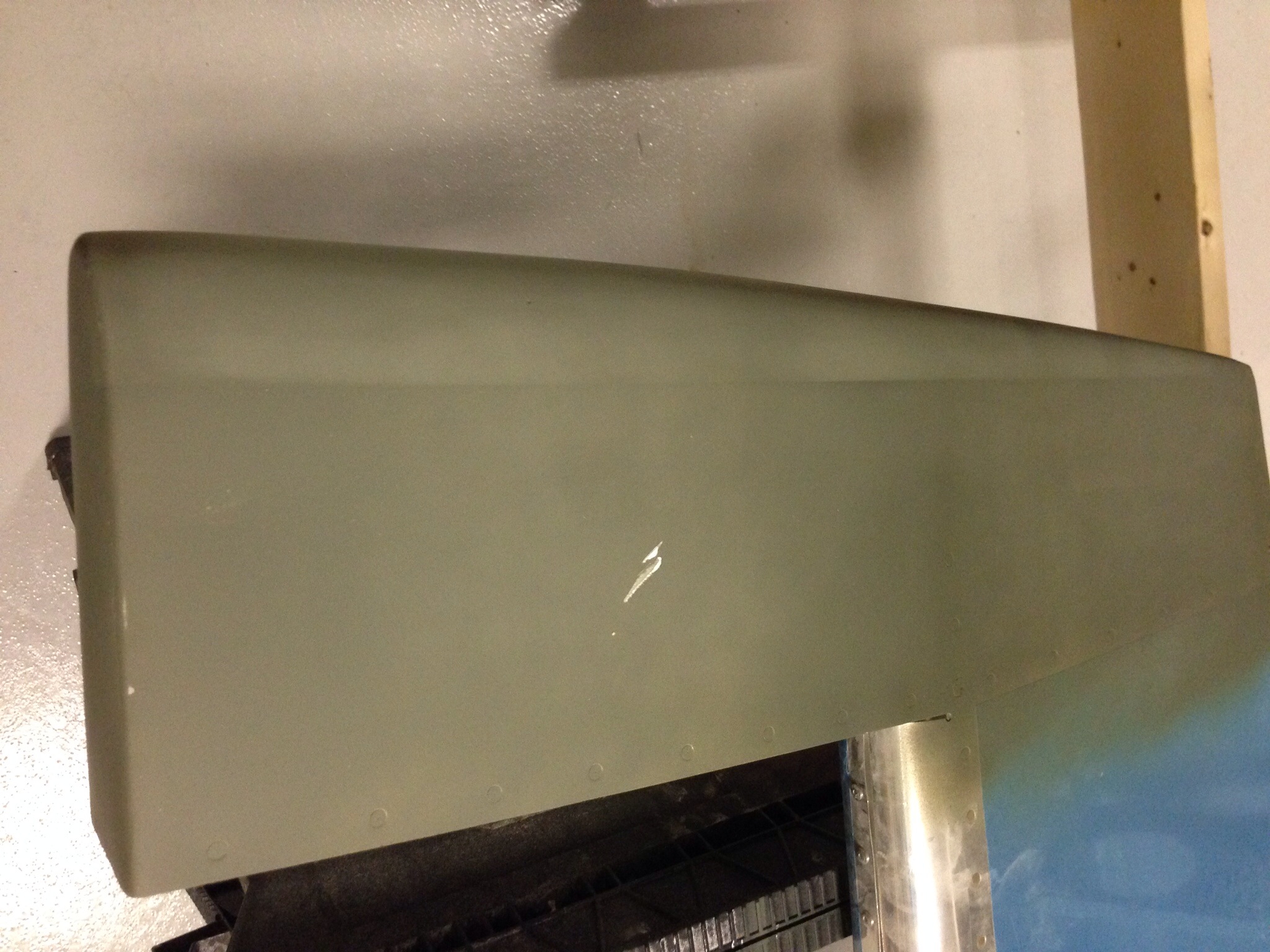

As you can see, there was quite a bit of corrosion between the two surfaces. I’m very happy I took the time to correct this and avoid potential problems down the road. I spent more time inspecting other areas of the tail cone and could find no other signs of corrosion, so I’m confident this is the extent of the damage. It took a few 3M pads to get all of this cleaned up, but after about an hour it was down to shiny smooth metal again. I was concerned about how much I had to grind away on the bulkhead, but a call to Vans alleviated my fears as they said I should be good to go. I removed the original primer (which was not applied very well, I admit) and did a thourough wipe down with MEK before properly priming with my SEM.

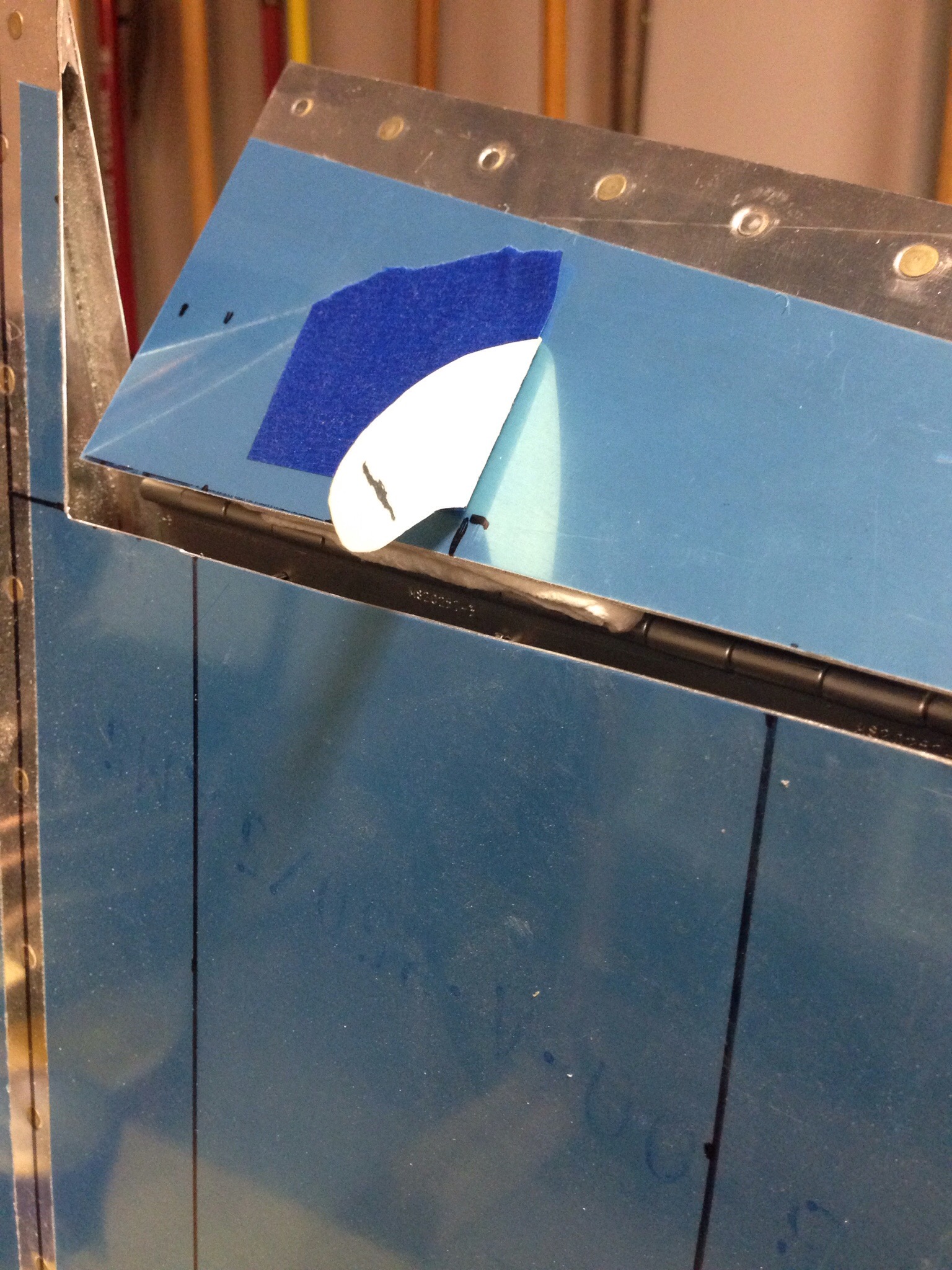

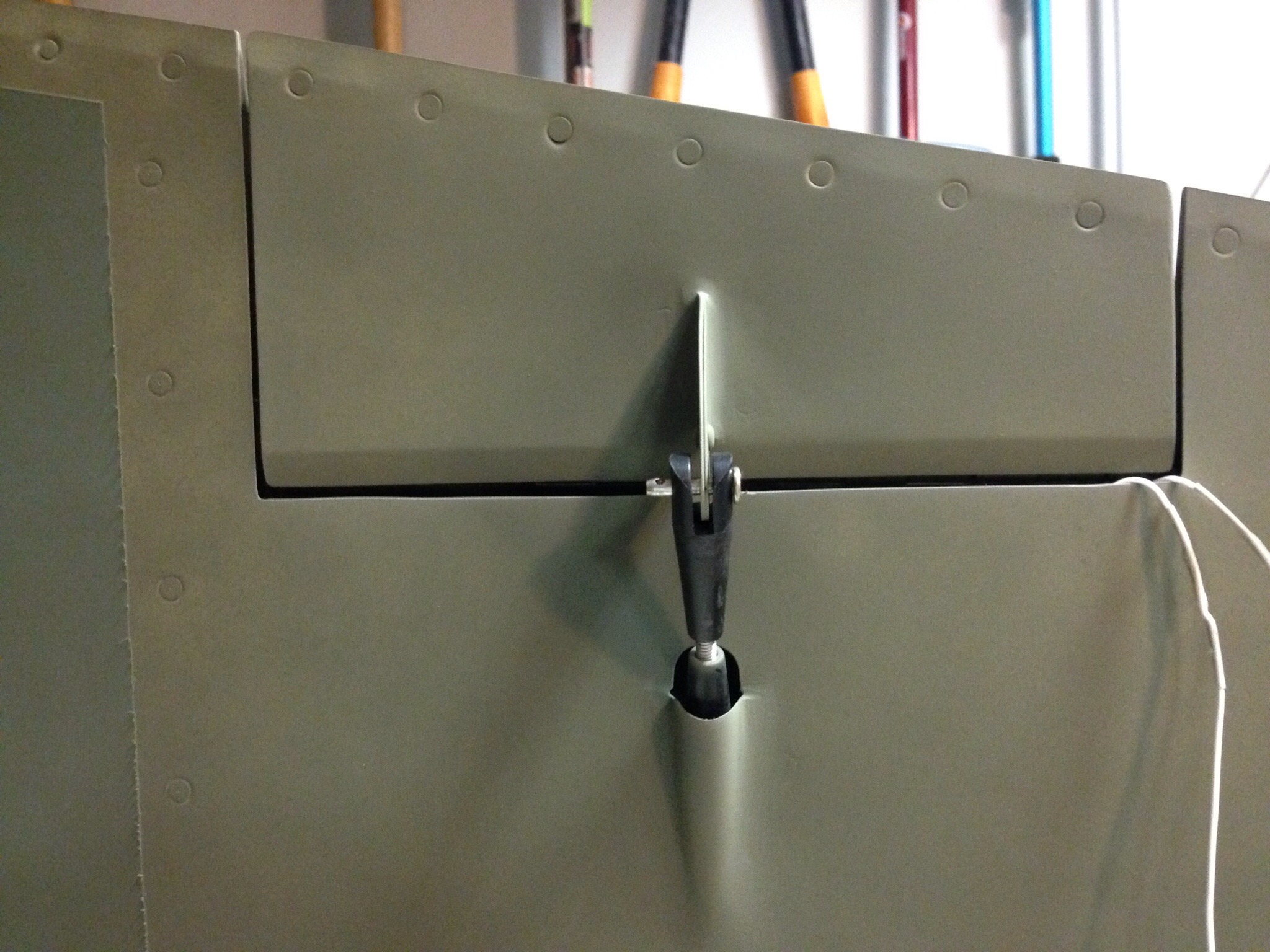

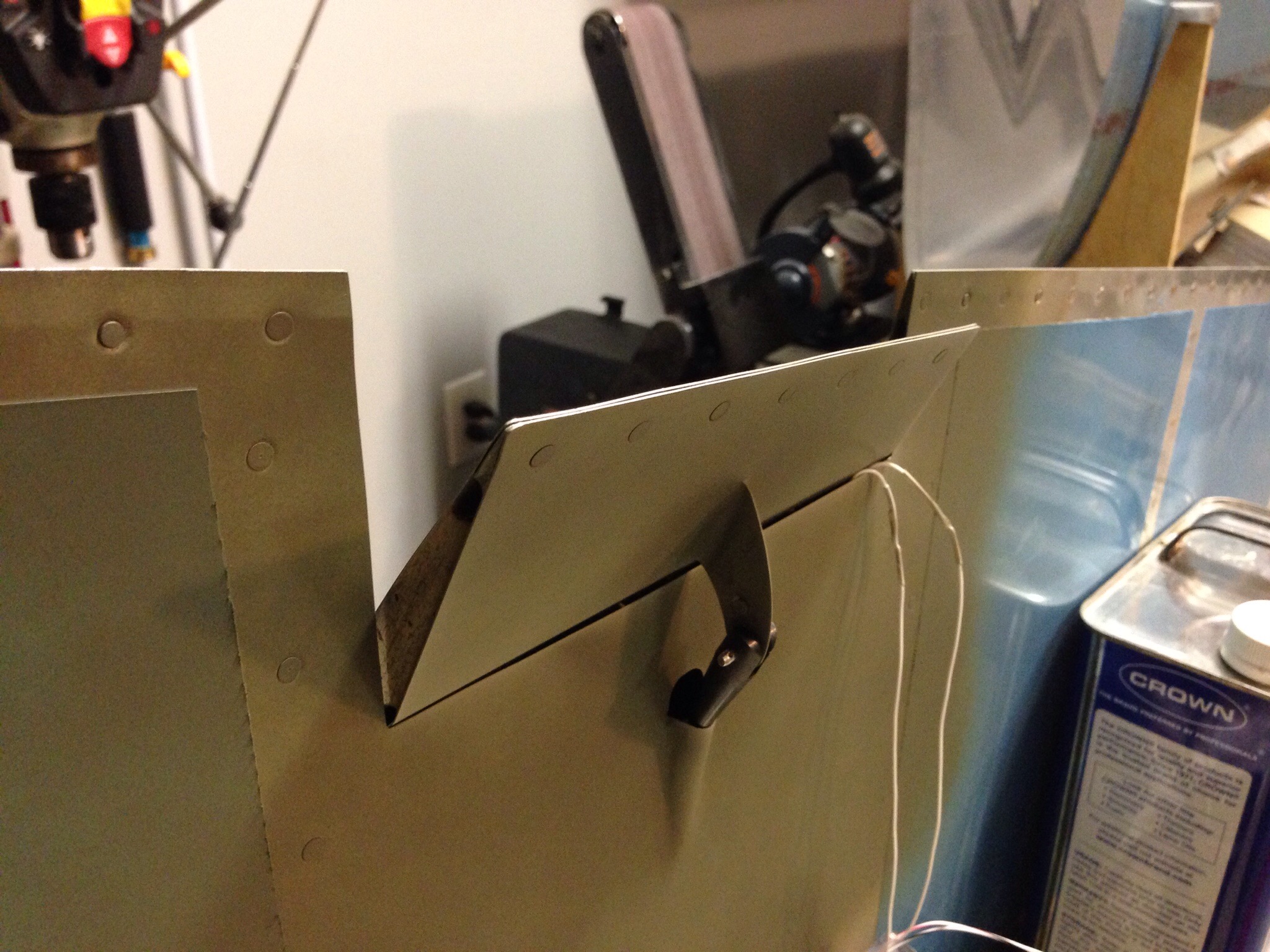

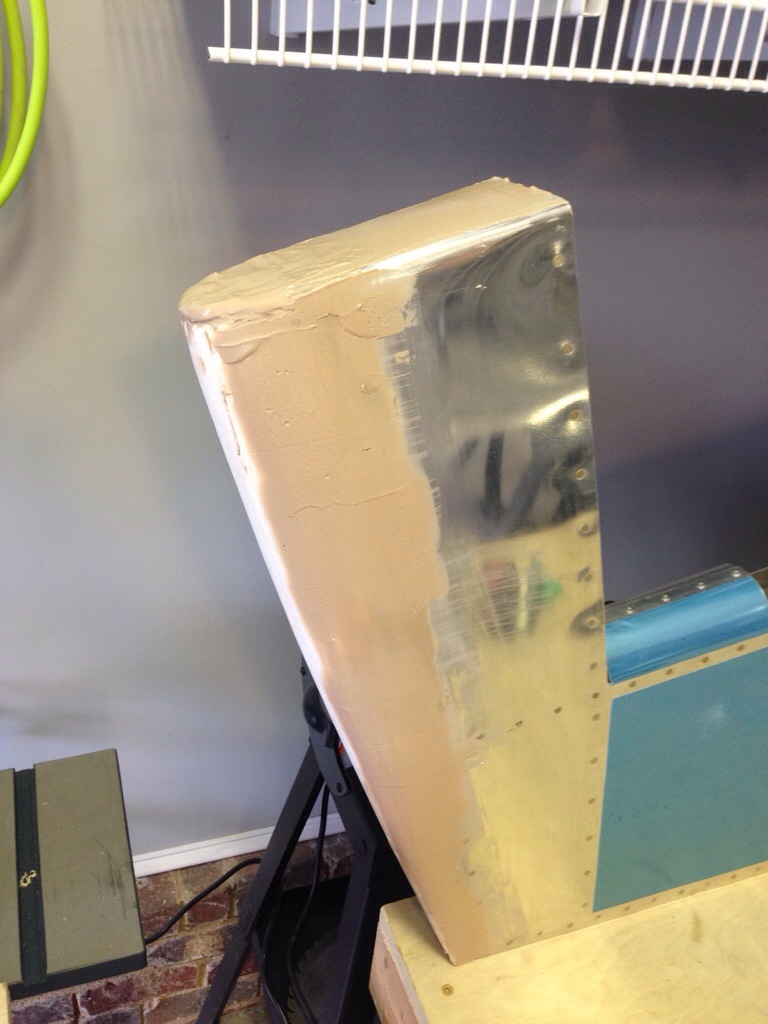

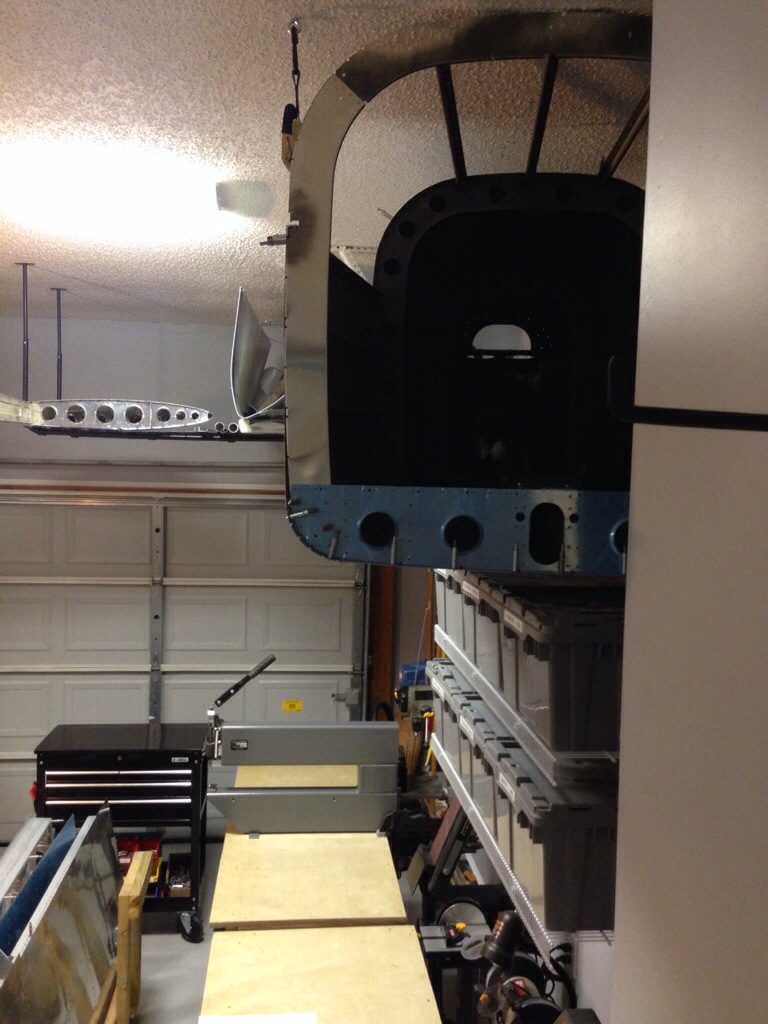

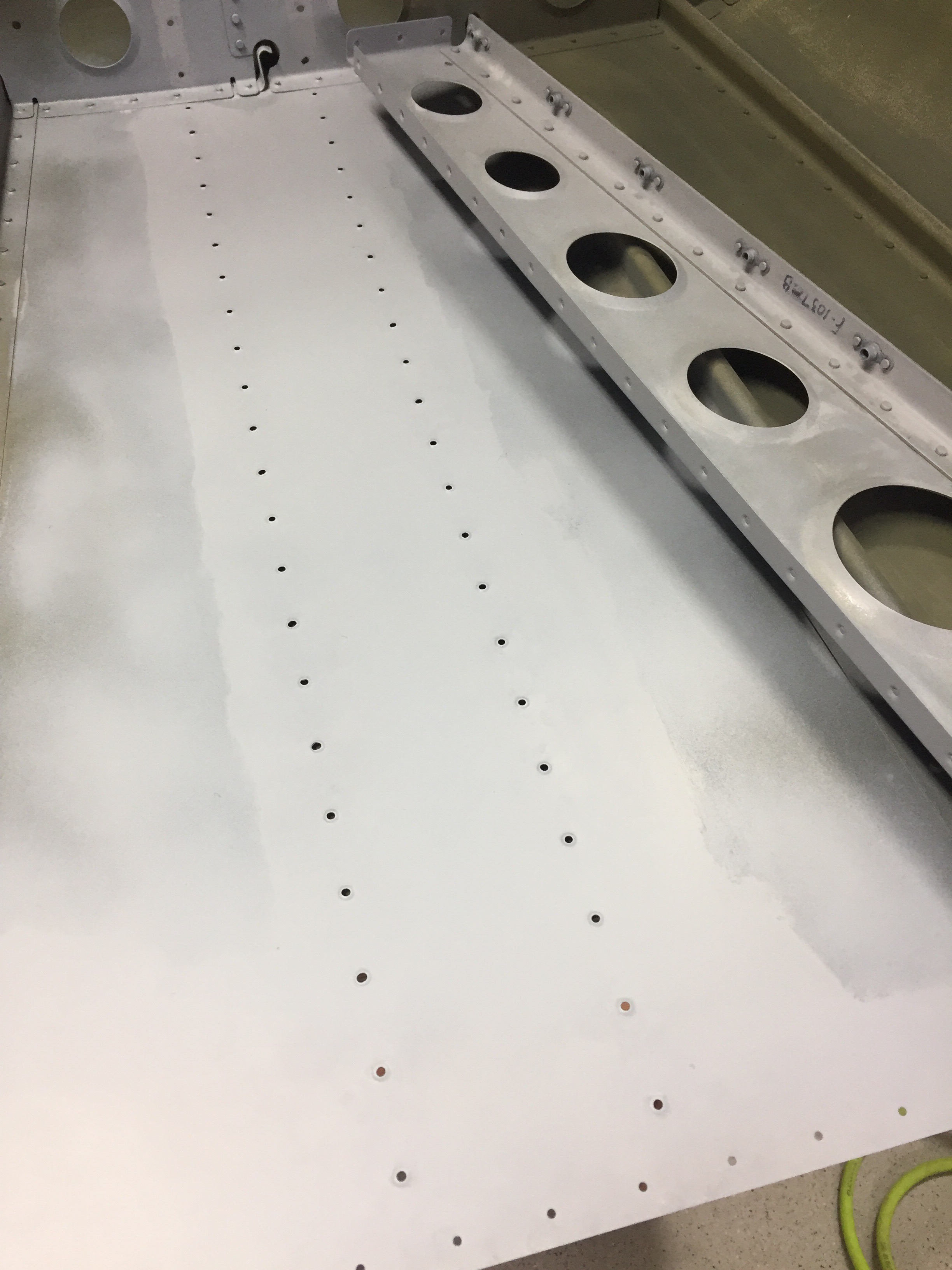

I did notice a small stress crack in the bulkhead lightning hole flange that I stop drilled upon Vans’ advice. I was able to move forward after this brief fix delay and was back on track. However, the next step was to mate the tail cone to the fuselage assembly. That requires getting rid of the sawhorses and coming up with a long term stand for the fuselage structure.

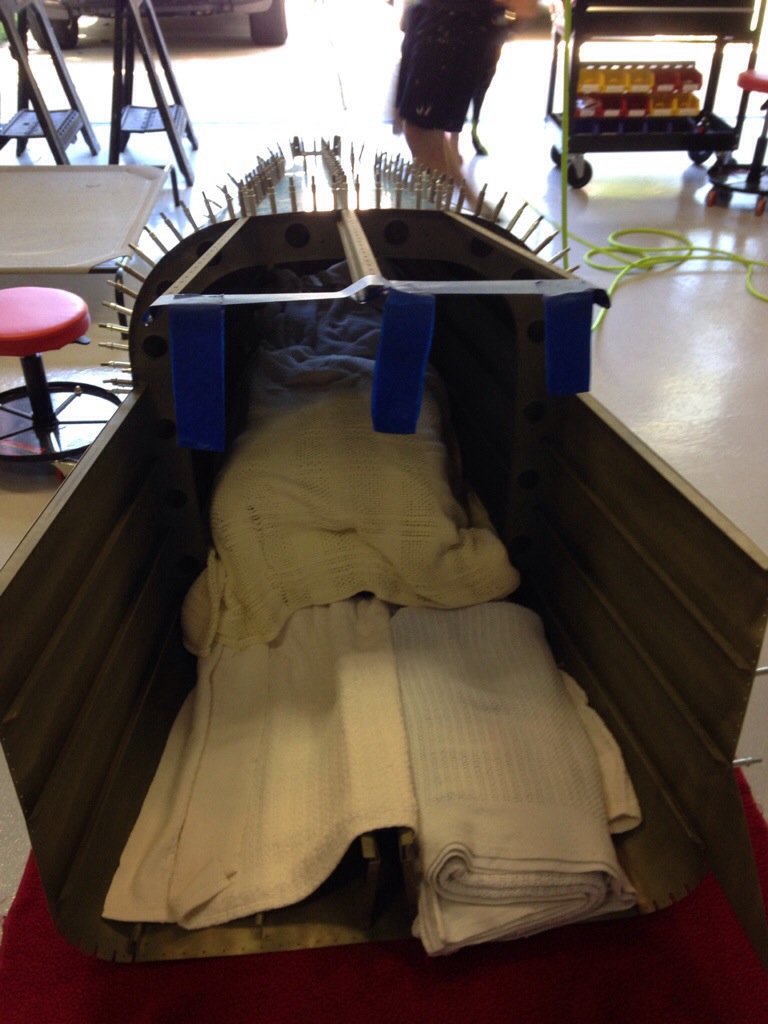

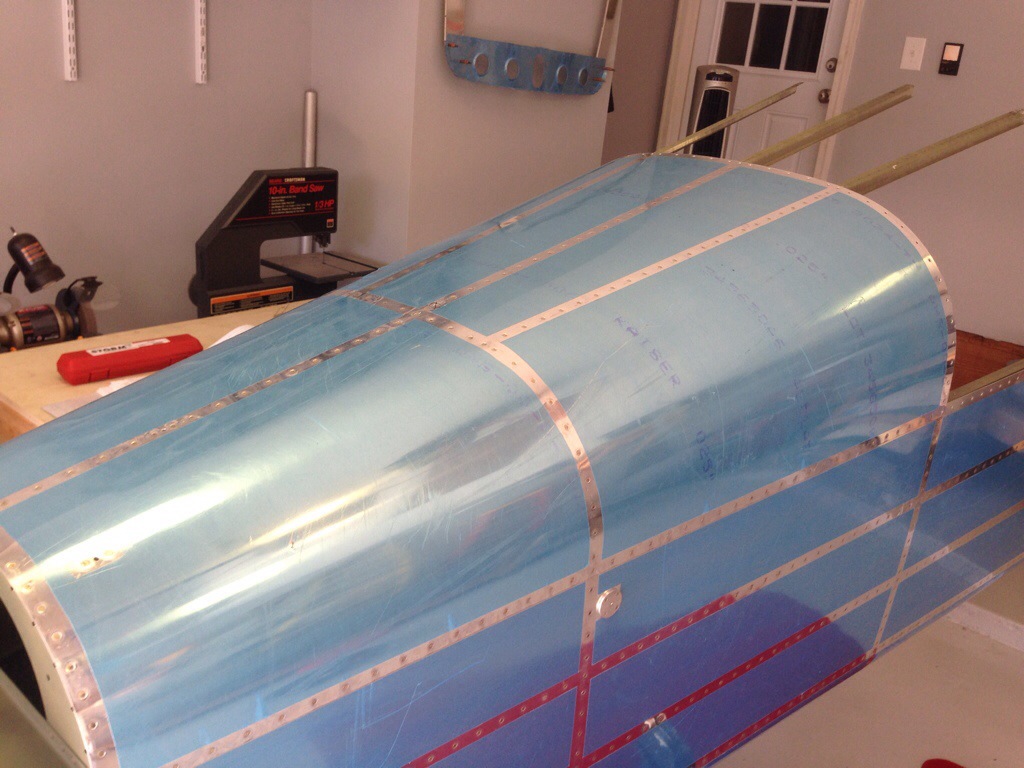

I checked out a few other build logs and decided to copy Justin Twilbeck and went with a four caster design with pillars for each side of the spar pass through and one each for the firewall and bulkhead near the steps. Using 2x4s and some OSB, I estimated the deminsions putting the structure at a nice working height, keeping in mind the cabin top and the height of my garage door. I won’t be able to mount the gear free hanging on this stand, but it will allow easy access and a comfortable working height for the next year or so. I put a bit of felt on the two bulkhead cross pieces and am pretty pleased with how securely it holds the fuselage. It also rolls quite easily which is good because the shop is filling up quickly!

Next up is actually mating the tail cone to this subassembly.