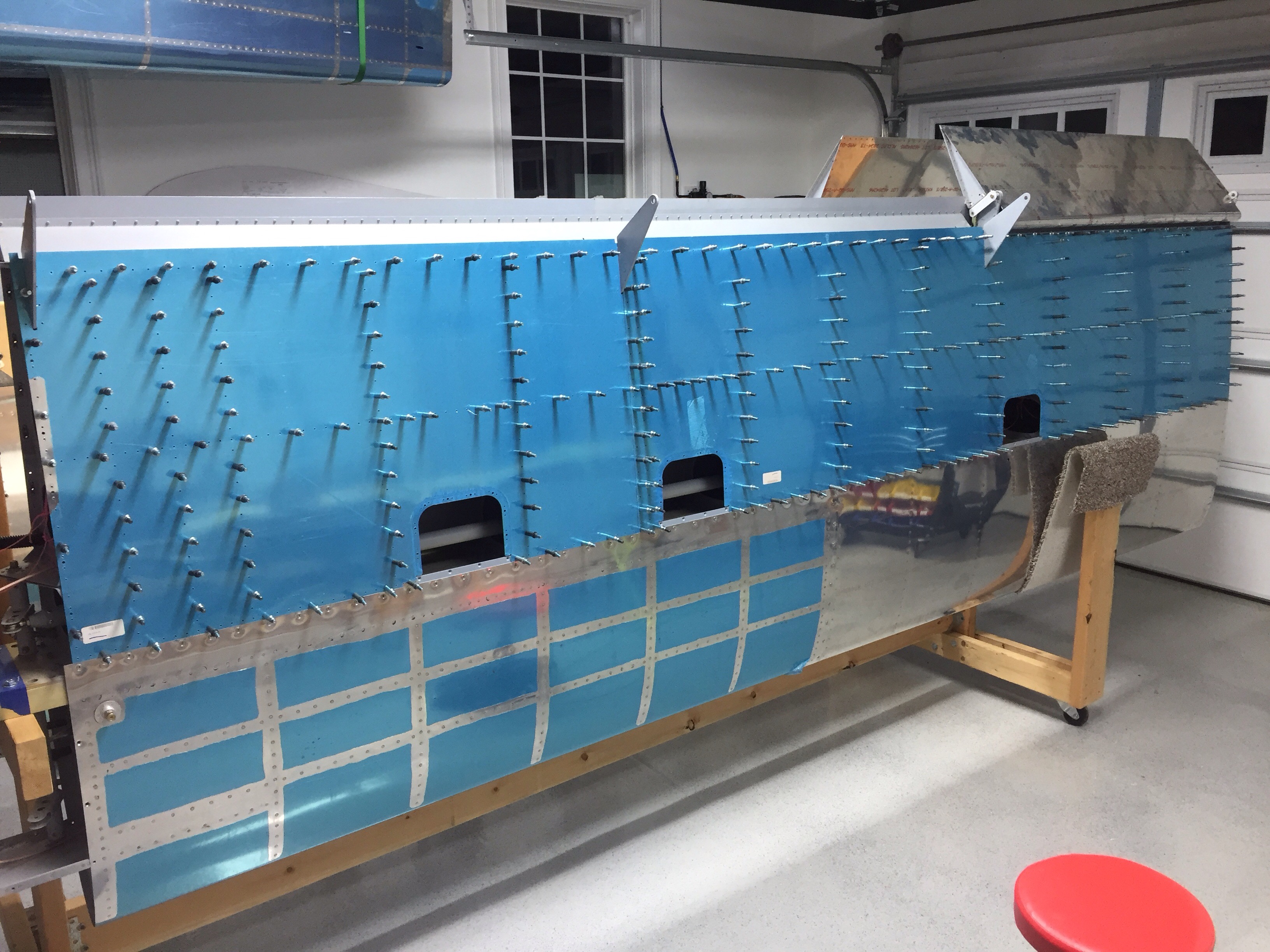

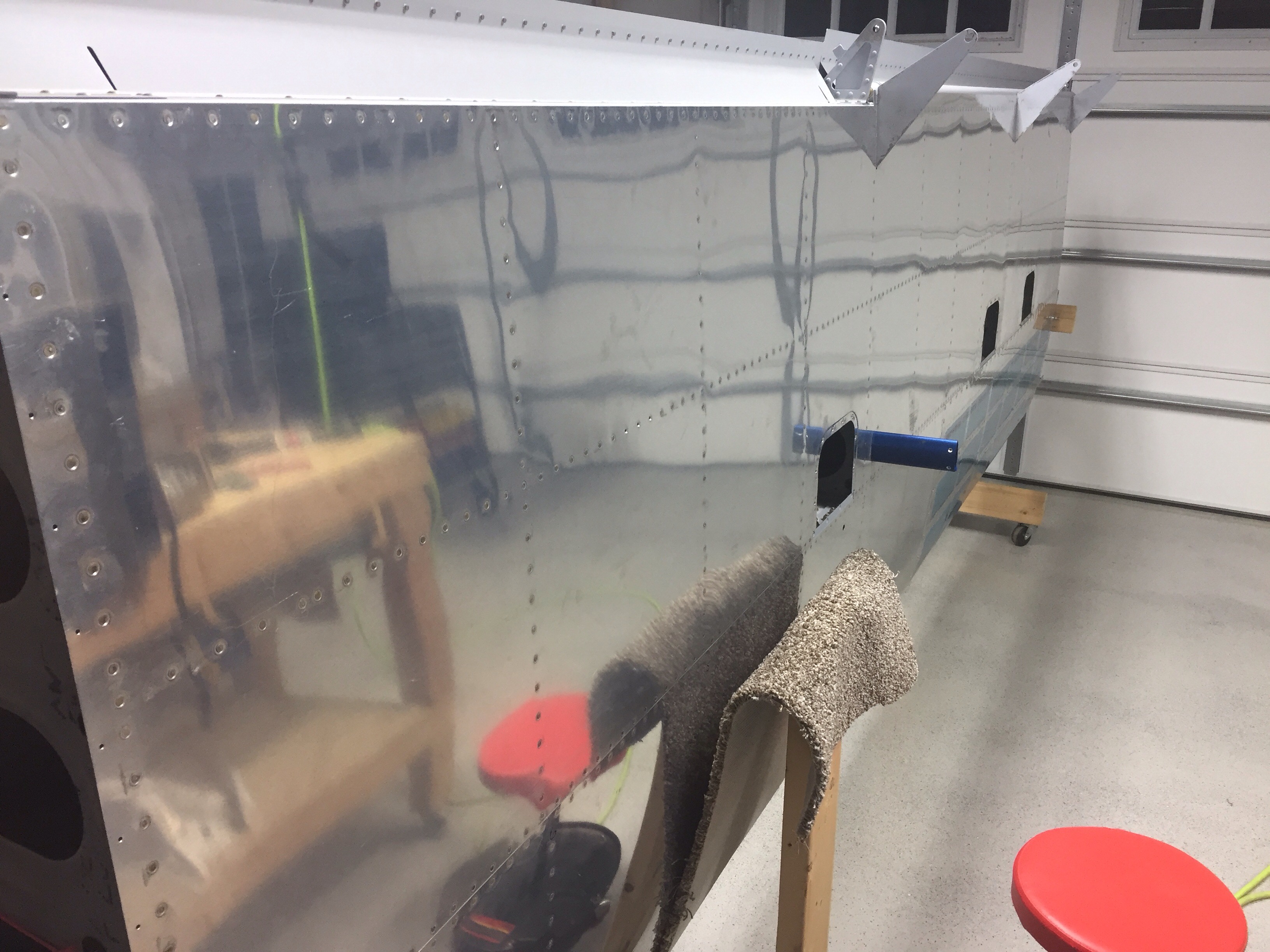

After a visit from my EAA chapter tech counselor and a great report card, I was confident in buttoning up the wings with the bottom skins. It takes a lot of clecos to position the skins and a lot of time spent drilling and deburring. Then the dimpling fun begins and priming.

The riveting process is another dreaded task, besides building the tanks. You have to start with the rear spar and bend the skins up. I used duct tape to help hold them in position and allowing me to rivet a few rivets at a time working from the rear down each rib.

Overall, it really wasn’t bad. I managed to get the entire skin done alone except for three rivets where my arms just weren’t long enough. I had the wife man the gun for those on the j-channel.

On the left wing, I installed the pitot mount. I also got the aileron trim servo hooked up mechanically and electrically with a micro Molex connector. I was worried that the springs on the setup would be a pain to install, but again, it wasn’t too bad. No picture, as once the springs are on, the access panel goes on.

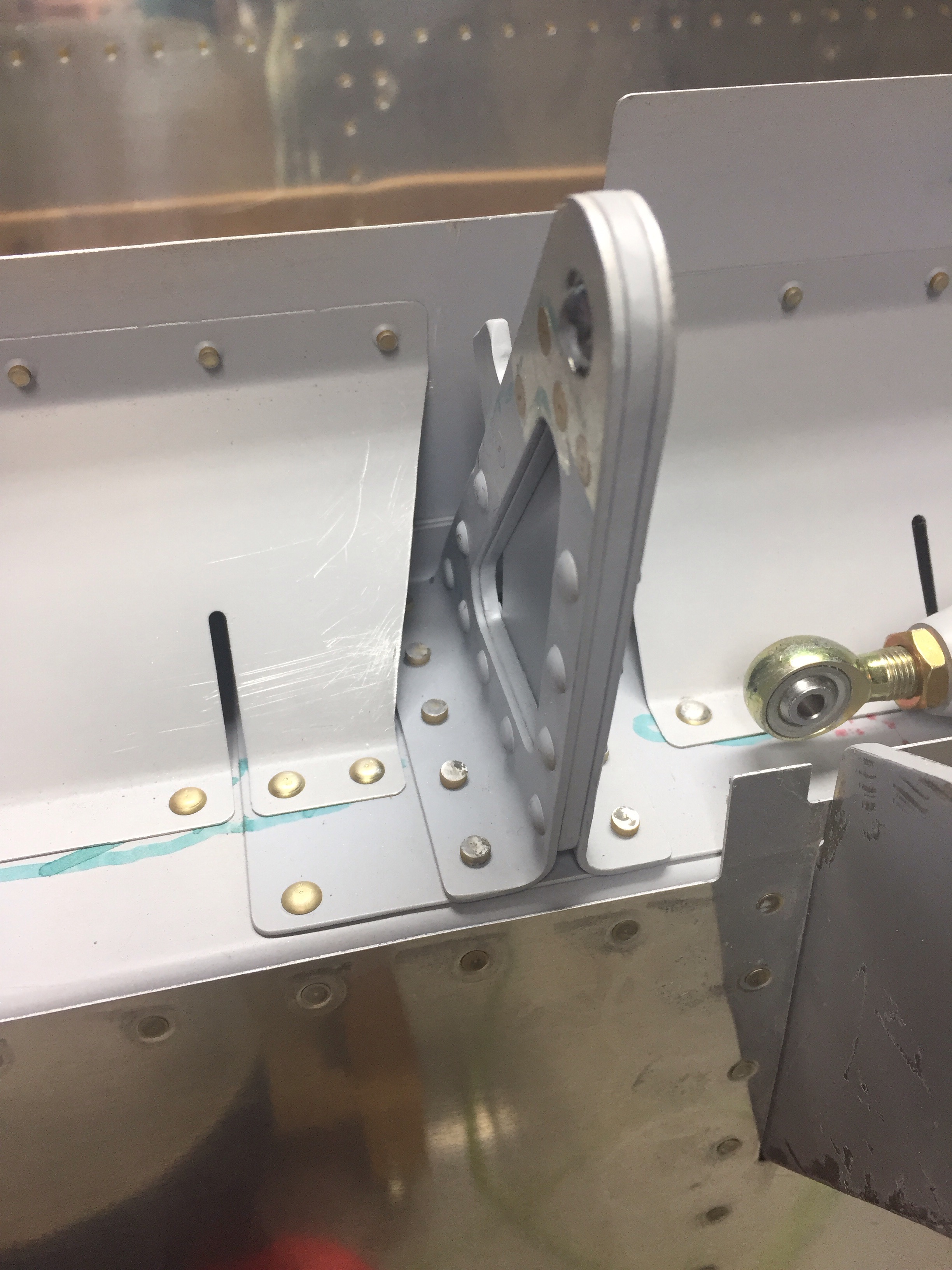

Finally, before replacing the aileron and flaps, I complied with the service bulletin regarding the aileron mounting bracket. Other builds have suffered cracking and the gap fairing must be cut back to allow inspections at regular intervals. Replacing it is not recommended per Vans, as it can cause more damage trying to remove the rivets than replacing it. A quick job with the Dremel tool.