There is an excellent excuse on why no recent posts have appeared. I’ve been TDY (temporary duty) at Sheppard AFB, located in lovely Wichita Falls, Texas, for about two months. While this place chalks up to the armpit of the Midwest, I was determined to get out and enjoy myself during the three months that I’m here. Luckily, another class mate, Justin, in my Aircraft Maintenance Officer training is a private pilot and we quickly found a few great places to airport bum meeting some great folks and getting a few flights under our belts. John Hooker, located at Wichita Valley Airport (F14), built a very nice RV-10 several years ago and was happy to show me around and give me some tips. Ironically, a unique feature spurred my memory and after digging through Oshkosh photos from four years ago, I realized I had seen his airplane in person. When we couldn’t find any good reason not to fly, he offered to take me for a quick hop along the Red River and gave me plenty of stick time. I’ve been attending the weekly Sunday evening social at F14 whenever my schedule permits.

The most exciting opportunity came with a visit to Houston and an amazing contact from VAF.net. Gaylon Koeining built, in my opinion, one of the best RV-10s flying. His choices and methods align very closely to my build and he has had to make a few modifications that I expect to make as well. After emailing back and forth for a few years, I finally got the chance to visit him in person. Gaylon was gracious enough to invite me down and show off his beautiful airplane.

My classmate was up for the adventure and we decided to make a weekend out of it by renting a very well running, very poorly equipped, but most importantly very cheap 172 to fly down south. At just under 100 knots, it was a three hour flight with a fuel stop at College Station. By the time we landed, we were down to only the nav and position lights working with no taxi, landing, or beacon light operable. You get what you pay for.

Carl Martin, who owns and flies a RV-6A, was kind enough to host us for the weekend. The community that exists in aviation, especially the RV neighborhood, never ceases to amaze me. He saw a post of mine about heading south and in two weeks, had a hell of a weekend lined up for us. He met us at Pearland Rgnl (LVJ) and had a hangar waiting for our crappy 172 that didn’t deserve the shelter. Dinner was lined up with a coworker from NASA and her husband, a retired USAF Col, who had some great stories. After a few drinks at their house, we got some rest for a big day on Saturday.

The morning was spent at Gaylon’s hangar home at Polly Ranch (7XS0). He had the top cowling off and was ready for my endless barrage of questions. Conversation flowed for several hours with a lot of technical discussion and tips/tricks being shared. I took a ton of close up pictures to use as reference and really benefited from his experience. Gaylon is an amazing guy who shared all of his secrets and even gave me ideas on making his ideas better. I only hope I can pass my experience on one day as he did for me. My biggest take aways from his build were around the Show Planes cowl, cooling, SDS EFI, and air conditioning setup. It was also great to see Jonathan’s (Plane Schemer) paint work up close. Truly show quality that gives me motivation to finish my build.

After lunch, Carl whisked us over to Songbird Ranch (91TS) where we met up with his close friends and formation partners. One of them has built several RV’s including a very nice 10 and really cool 7. After a little hangar talk the guys organized a three ship and each one of us climbed in a plane to go have some fun underneath the 3000′ ceiling. I went with Nick in the 10 while my buddy and Carl got seat time in the RV-7 and RV-4, most of that time being spent in close formation with us or upside down! Nick was awesome and gave me the stick the whole flight, even trusting me with a crosswind landing on his 30′ wide private strip. It wasn’t pretty, but I got us down and logged another RV-10 landing in the log book.

With Saturday almost as good as Oshkosh, Justin and I thought Sunday would be a day of rest while waiting for weather to improve to fly our allegedly IFR certified 172 back VFR to CWC. Little did we know it would turn into a behind the scenes tour at the Collings Foundation with a quick pit stop at the Houston Space Center. Carl seems to know everyone who flies in Houston thanks to his time at NASA, so we checked out another guy’s RV-4 and v-tailed Bonanza at Ellington Field. Sitting on the ramp, we saw a ME-262 and while checking it out, got called into the restoration hangars to climb all over the foundation’s F-100, A-4, and F-4, all of which were in flying condition.

With winds at our backs and enough of a ceiling to skud run north, we climbed in the 172, now with only the position and right nav working (shhh don’t tell the FAA), and launched towards Kickapoo. The tail wind had us screaming over the ground at 130 knots and got us back on base by 1500. It was an amazing weekend thanks to so many people, especially Carl Martin who played host, tour coordinator, chauffeur, friend, and co-pilot. What we thought would be just a nice weekend away from Sheppard turned into a trip to remember. Now, only another month until I can get back to work on my 10 and start taking advantage of the amazing capabilities of general aviation!

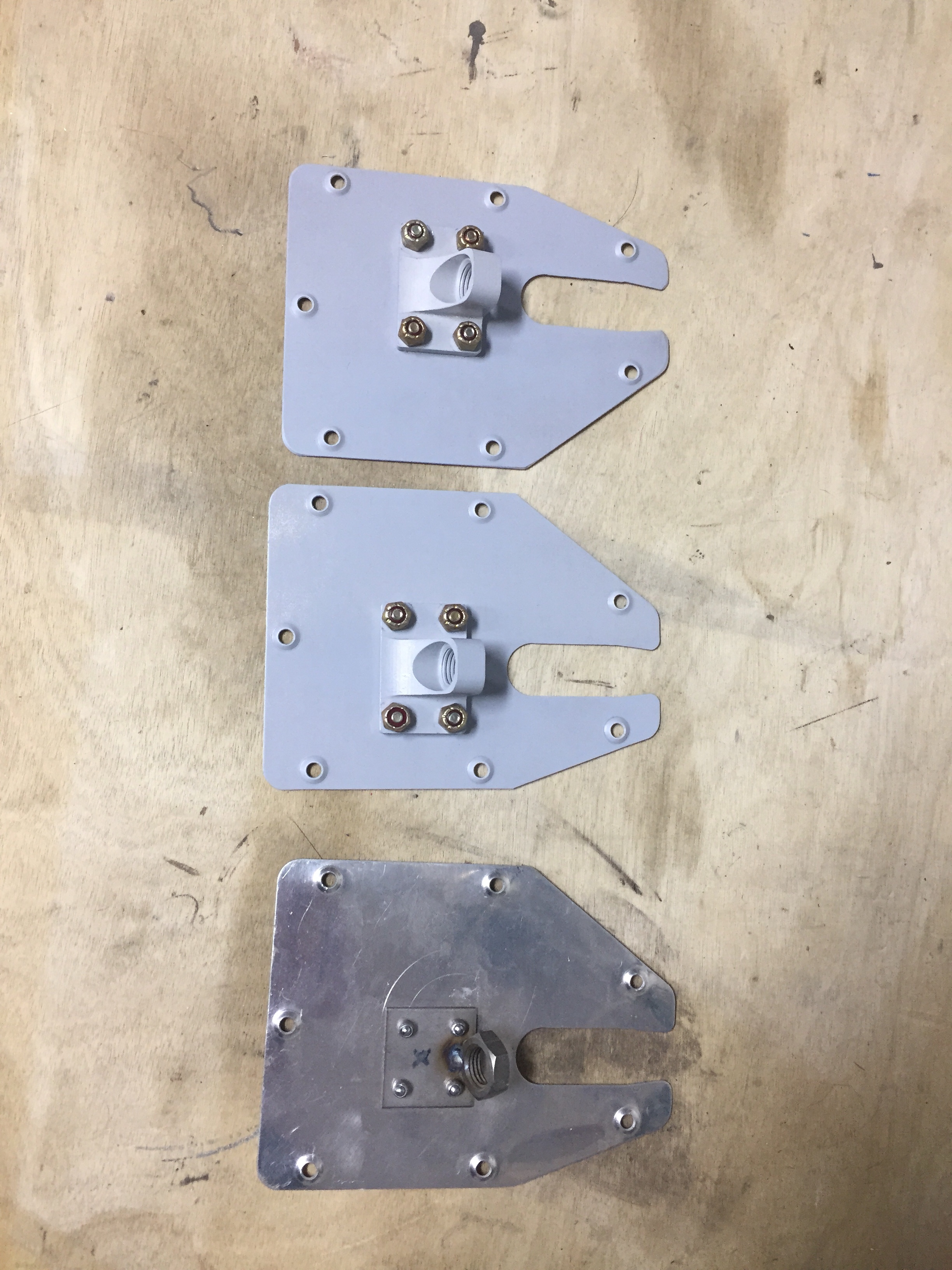

I also knocked out a few little projects, one being making new elevator trim bracket panels. I had the beefed up fittings sitting in the parts bin and finally ordered the new access panels. After countersinking and priming, the parts are ready to roll and comply with a SB from Van’s from many years ago. This is a common upgrade and an easy one at that.

I also knocked out a few little projects, one being making new elevator trim bracket panels. I had the beefed up fittings sitting in the parts bin and finally ordered the new access panels. After countersinking and priming, the parts are ready to roll and comply with a SB from Van’s from many years ago. This is a common upgrade and an easy one at that. Another little project wasn’t so little. I saved up a few tasks that needed to be completed inside the tail cone for one evening so I would only be crawling back there once (this time). The first was to support the tail better. I used two 1×4’s to bolt to the horizontal stabilizer mounts and put a caster on the bottom. While the fuselage cradle has been great, the rear support isn’t far enough back to support my weight so far aft without something heavy like an engine hanging off the front. So this was an easy fix and doesn’t take any room up in the shop. It’s still very easy to roll around and reposition as needed.

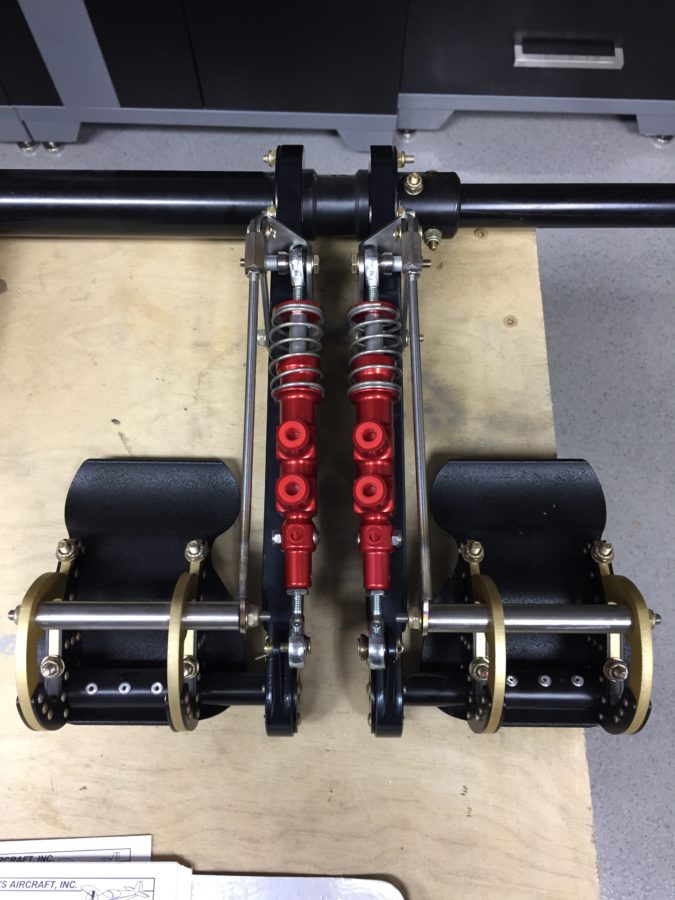

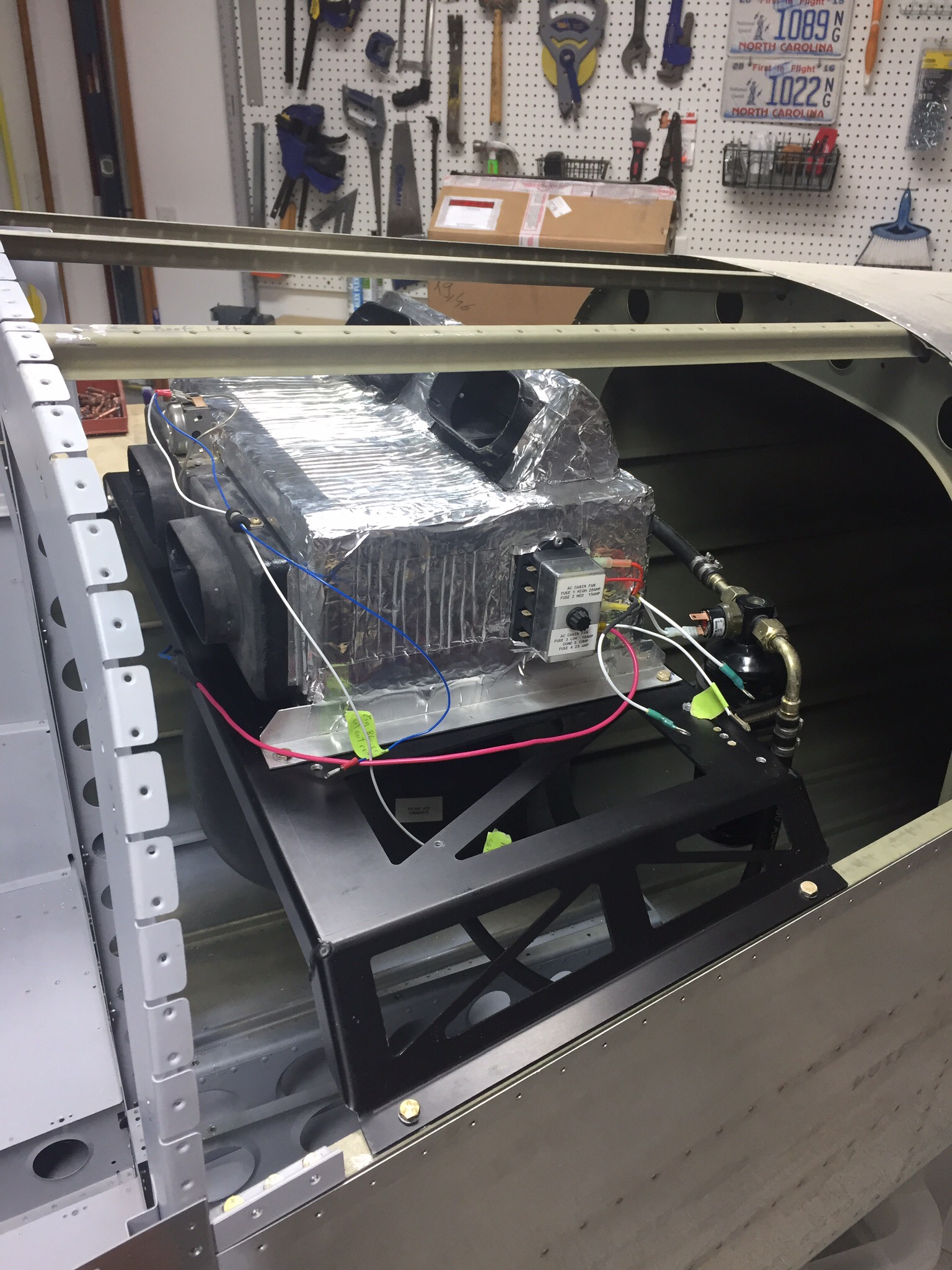

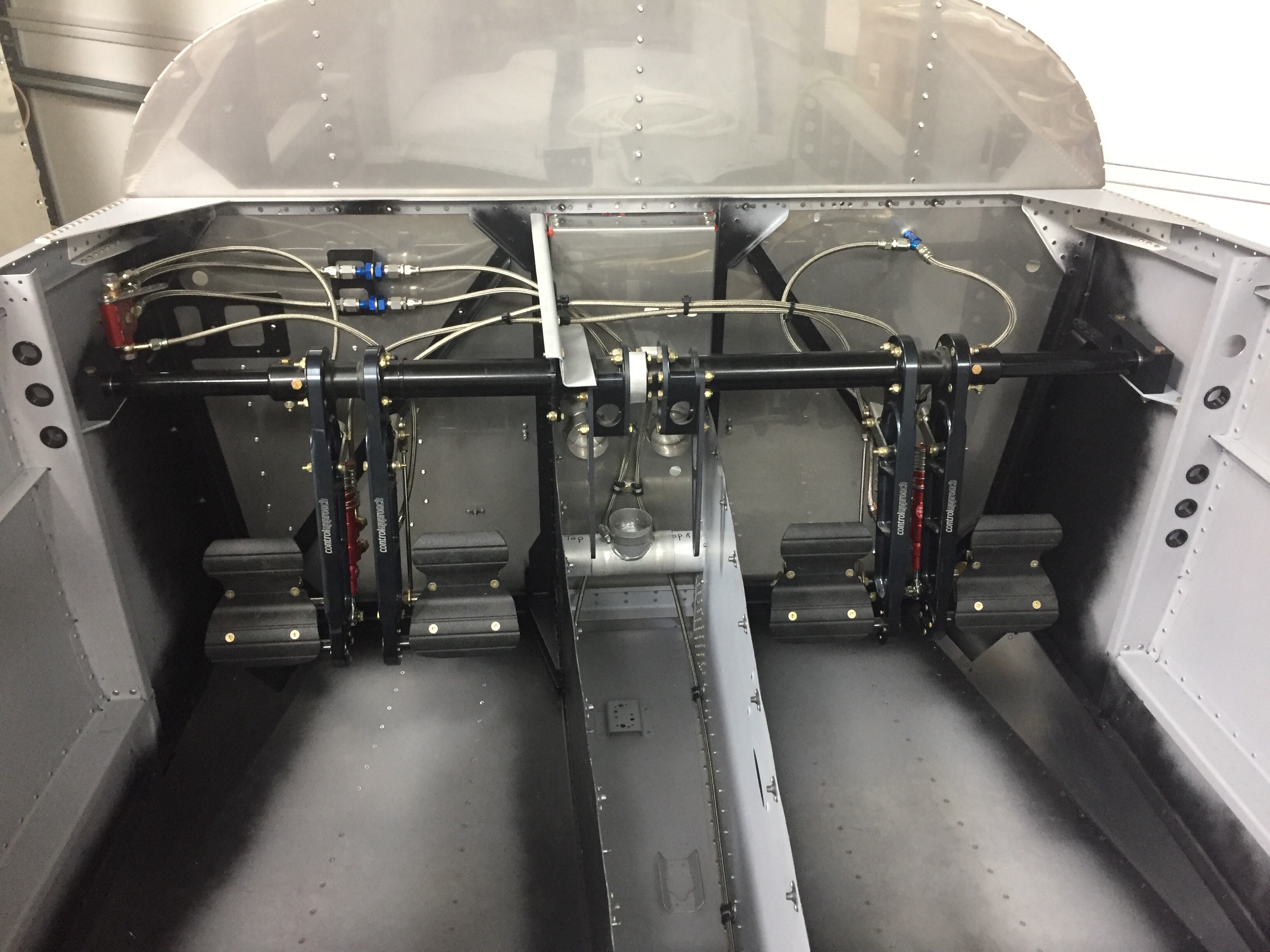

Another little project wasn’t so little. I saved up a few tasks that needed to be completed inside the tail cone for one evening so I would only be crawling back there once (this time). The first was to support the tail better. I used two 1×4’s to bolt to the horizontal stabilizer mounts and put a caster on the bottom. While the fuselage cradle has been great, the rear support isn’t far enough back to support my weight so far aft without something heavy like an engine hanging off the front. So this was an easy fix and doesn’t take any room up in the shop. It’s still very easy to roll around and reposition as needed. Inside the tail cone, I mounted the new static ports with pro-seal (no rivets this time) and hooked up static line that runs to where the ADAHRS will be mounted just behind the baggage bulkhead. The new static ports look way better than the original ones and I’m happy I made the change. The Safe Air 1 line kit makes it easy to run the tubing and create a leak free system. I also ran the rudder cables through the bulkheads and snap bushings. Ironically, the heads of the cables wouldn’t fit through the bushings without removing them and squeezing a bit. So basically, the cables were a pain to run instead of a quick two minute job. Lots of those in the build, I guess. I got them hooked to the arms on the rudder pedals which are inside the tunnel with the Control Approach pedals. With the A/C in there, it’s a tight fit for me!

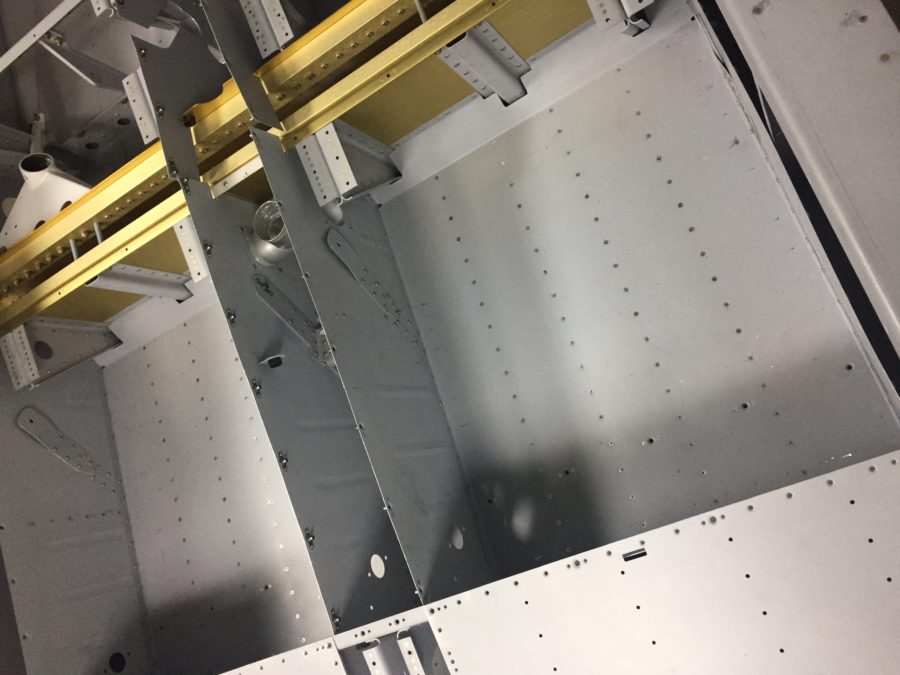

Inside the tail cone, I mounted the new static ports with pro-seal (no rivets this time) and hooked up static line that runs to where the ADAHRS will be mounted just behind the baggage bulkhead. The new static ports look way better than the original ones and I’m happy I made the change. The Safe Air 1 line kit makes it easy to run the tubing and create a leak free system. I also ran the rudder cables through the bulkheads and snap bushings. Ironically, the heads of the cables wouldn’t fit through the bushings without removing them and squeezing a bit. So basically, the cables were a pain to run instead of a quick two minute job. Lots of those in the build, I guess. I got them hooked to the arms on the rudder pedals which are inside the tunnel with the Control Approach pedals. With the A/C in there, it’s a tight fit for me! Lastly, I installed the doublers along the center of the fuselage for the transponder and ADS-B antennas to mount to. These will be Delta Pop blades and mount with two studs, so I need access from the tunnel / fuselage. Easy enough with a second set of hands to man the gun and me bucking.

Lastly, I installed the doublers along the center of the fuselage for the transponder and ADS-B antennas to mount to. These will be Delta Pop blades and mount with two studs, so I need access from the tunnel / fuselage. Easy enough with a second set of hands to man the gun and me bucking.