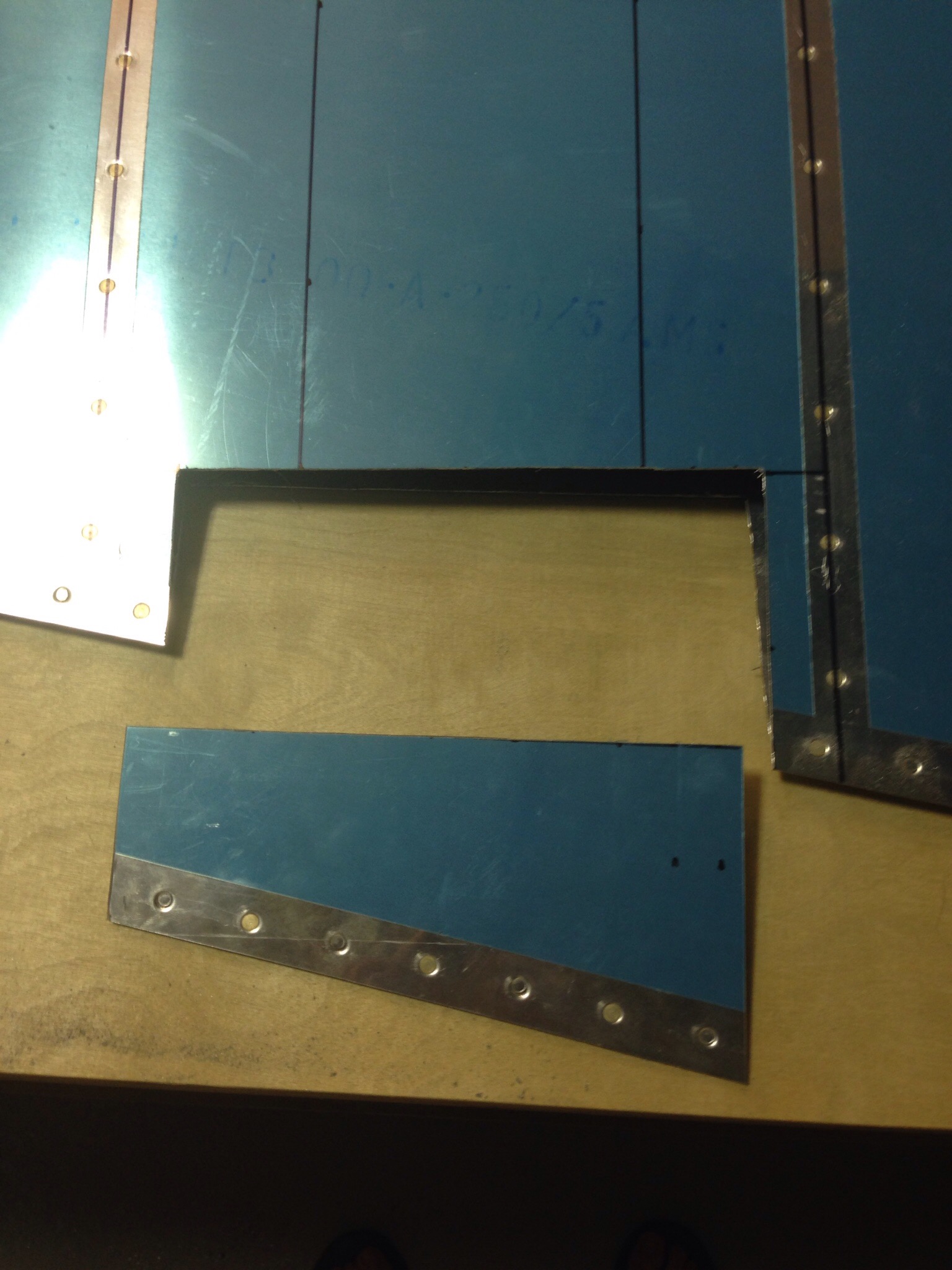

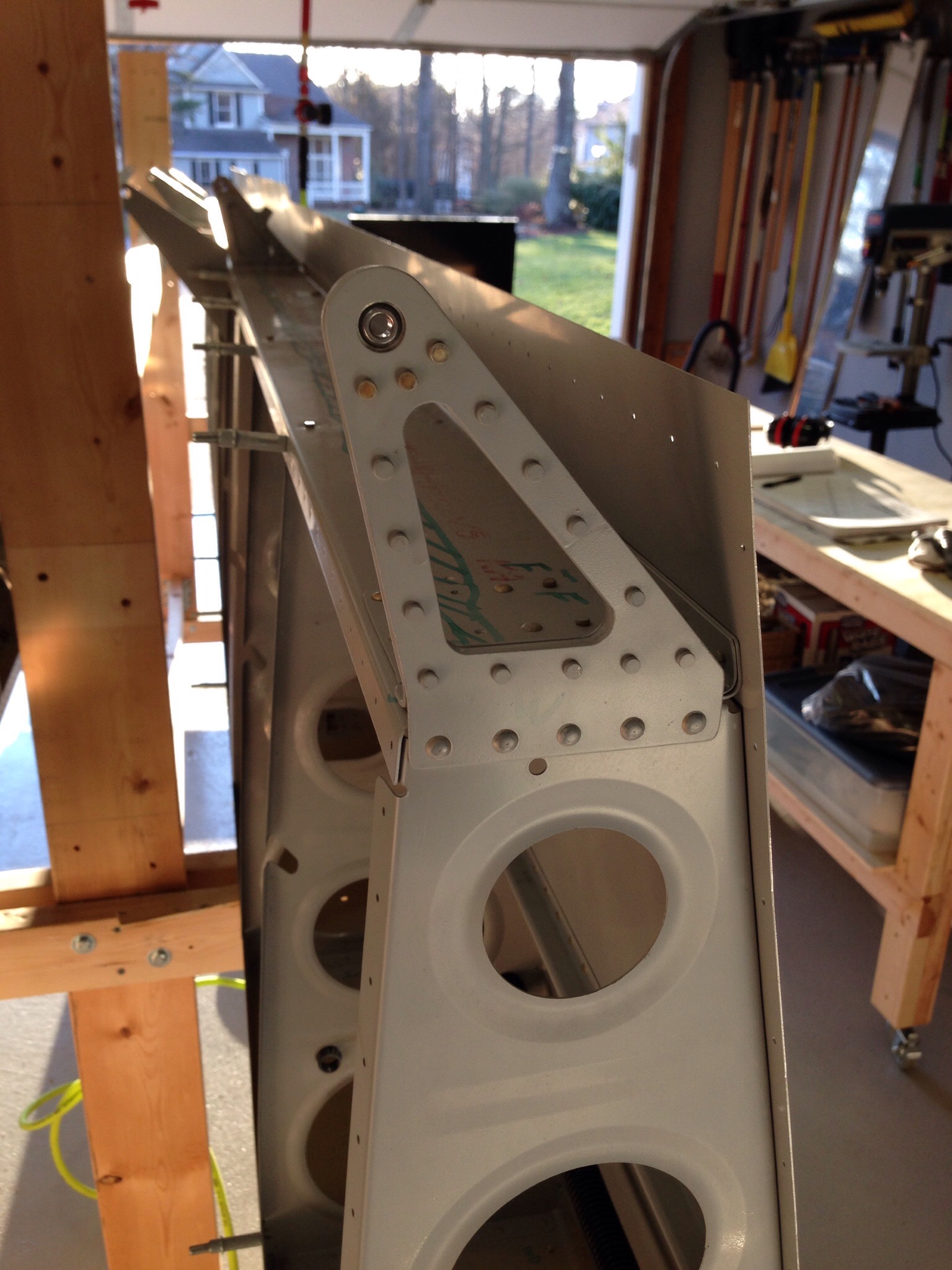

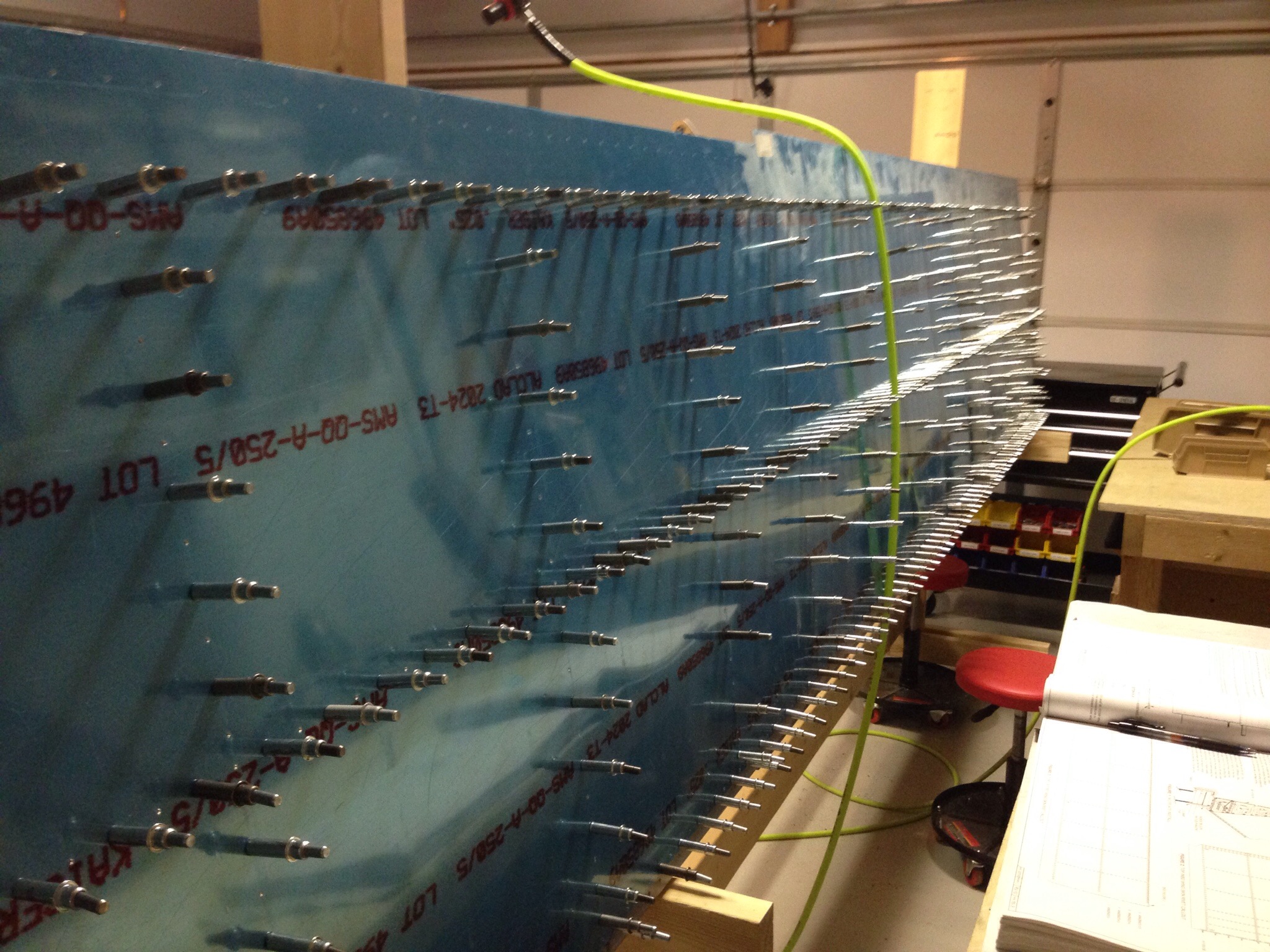

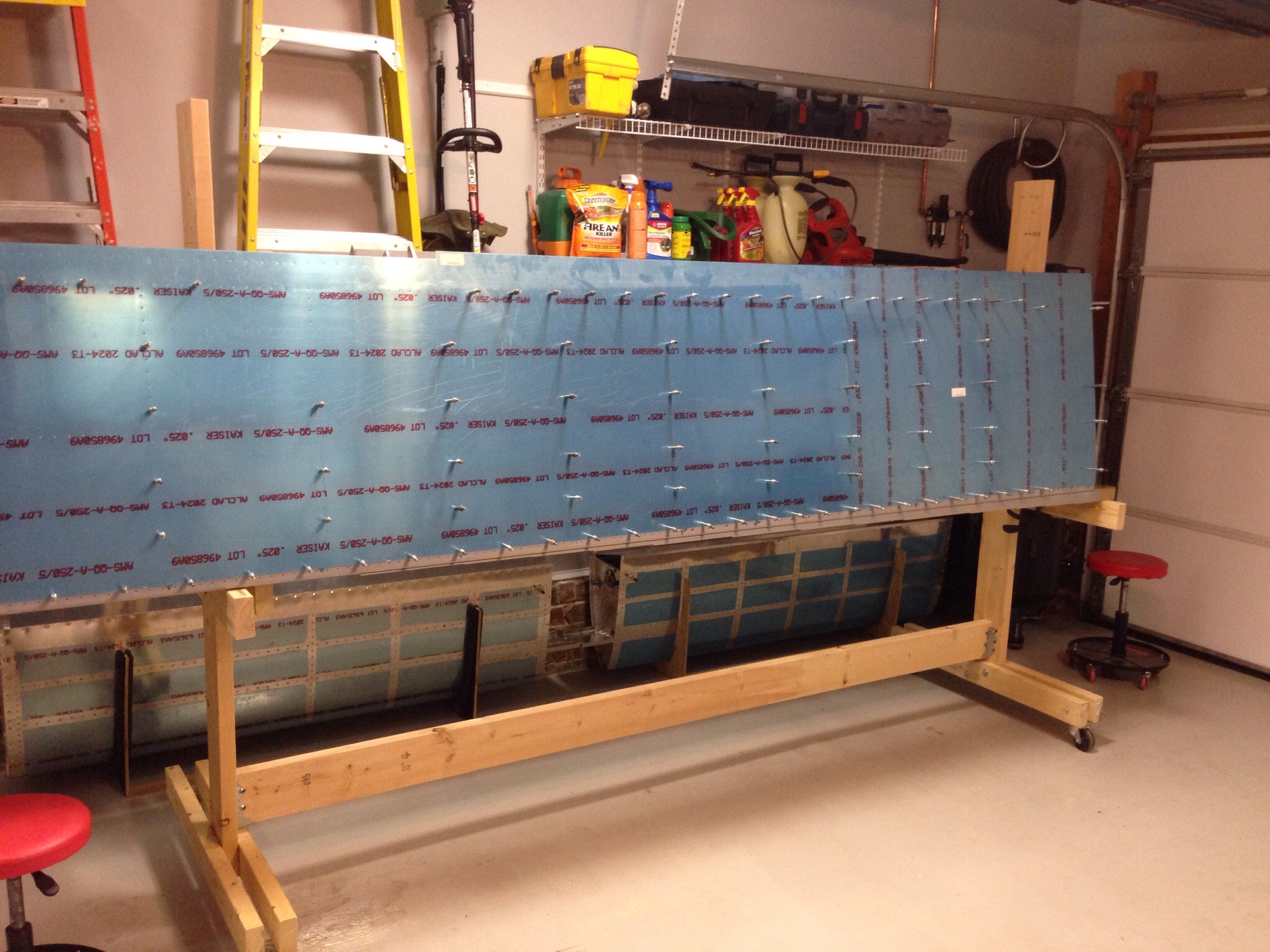

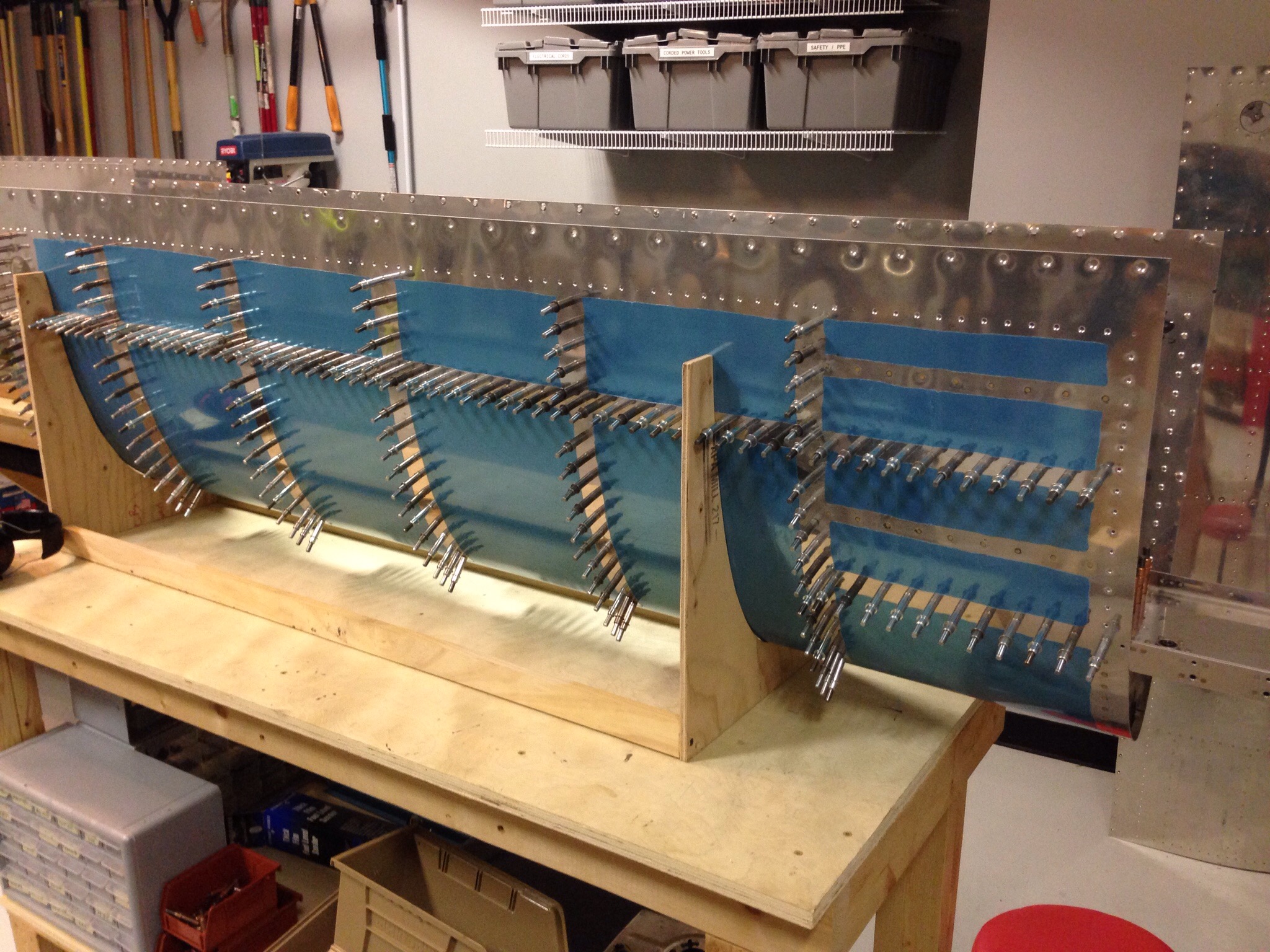

I have decided I don’t like leading edges. While they are beautiful and shapley, not to mention aerodynamically critical, they are a real pain in the ass to build. The real problem are the rib tips and how they just never want to fit right the first, second, and sometimes third time. But with enough patience, perserverance, and hammering (not really, but yes really), they will come together. After assembling and final drilling the components, everything got deburred, primed, and dimpled.

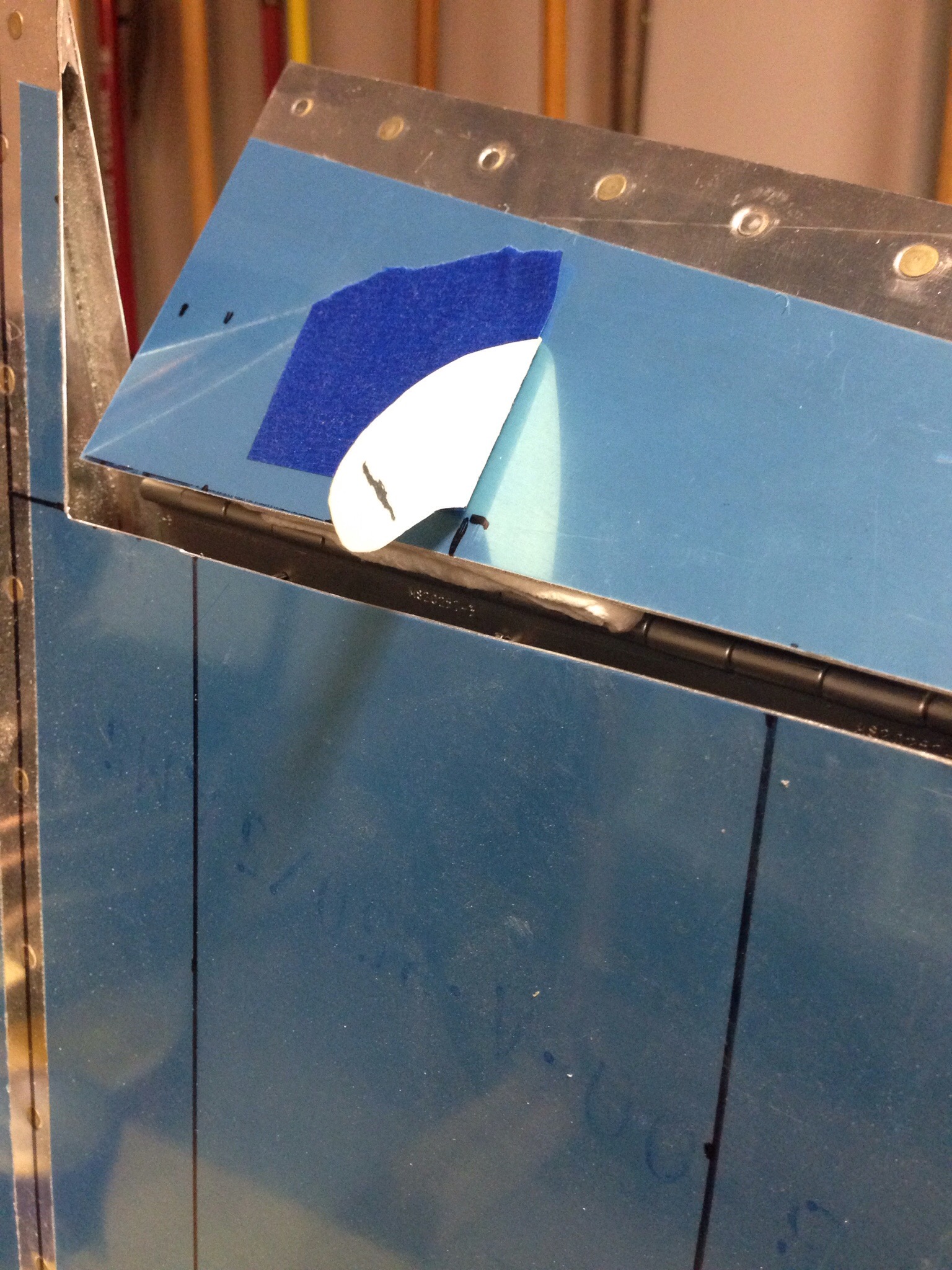

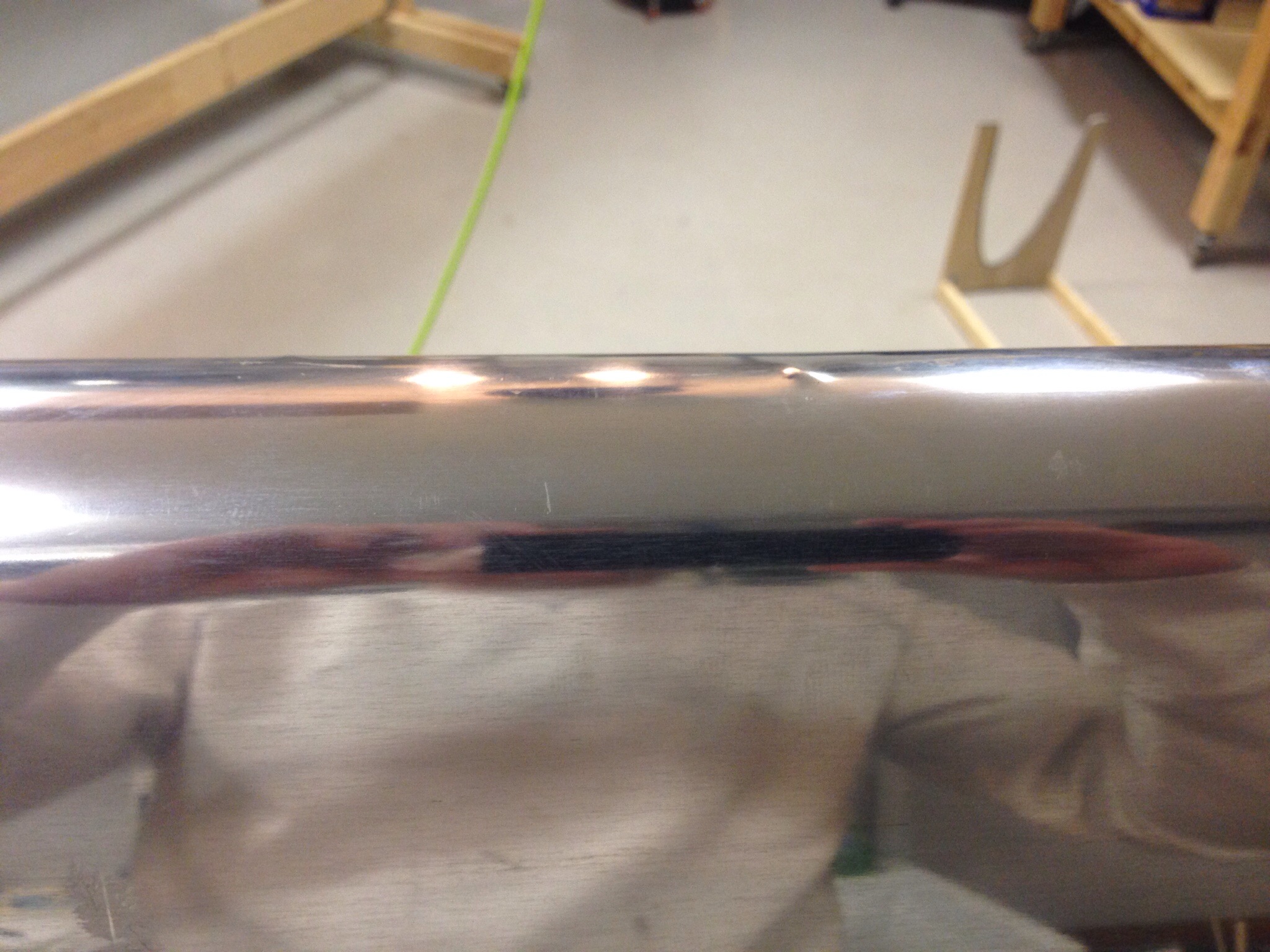

Of course now that I’ve done this four times, I figured out the easiest way to get the skin to wrap around the ribs is to start on the flat side, then work from end to the other around the profile of the skin. I also had the first “F**k-up” that will be a lasting oops on the project. I managed to drop the bucking bar and it seemingly bounced around the inside of the leading edge before finally dropping right in the bottom with a nice zit on the outside.

It’s not terrible and I was able to very gently hammer a bit back into place. It’ll just remind me that I built the airplane every time I do the preflight!

In other bad news, the fuel tanks gave me a 50/50 success rate. The left tank tested fine after the initial fixes cured. Not a single drop of moisture, which made me happy. This was confirmed after four days of water sitting in the tank.

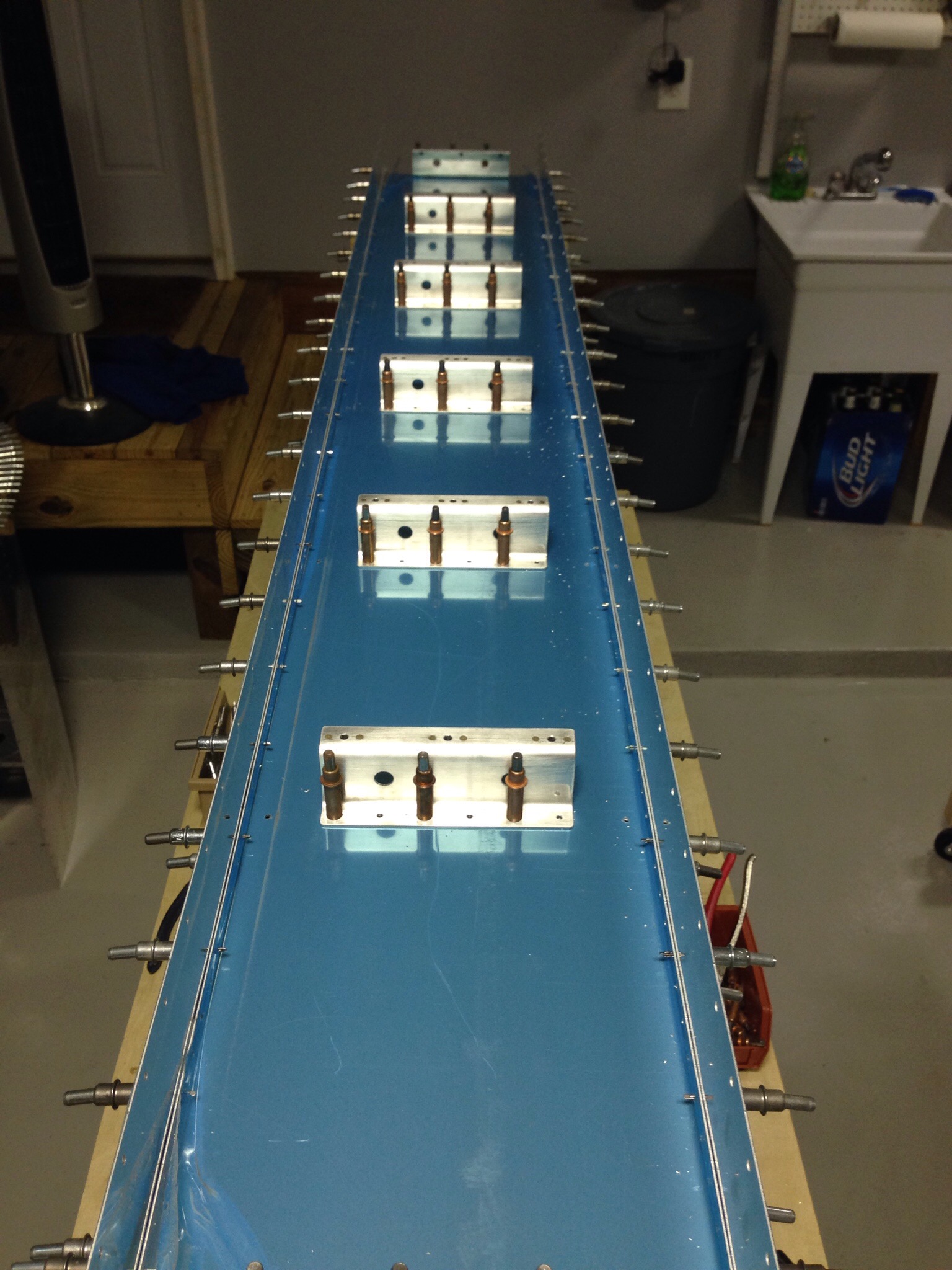

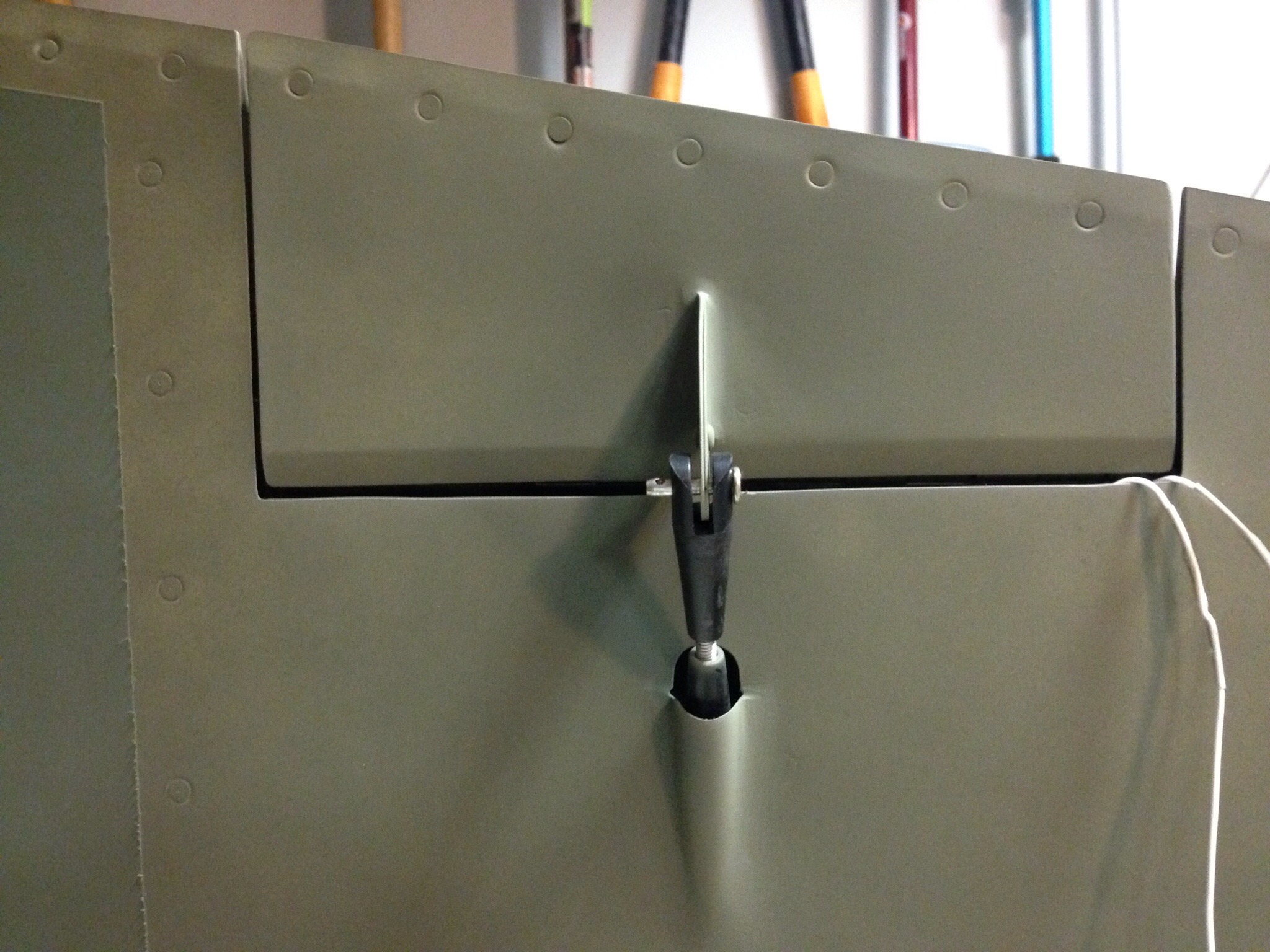

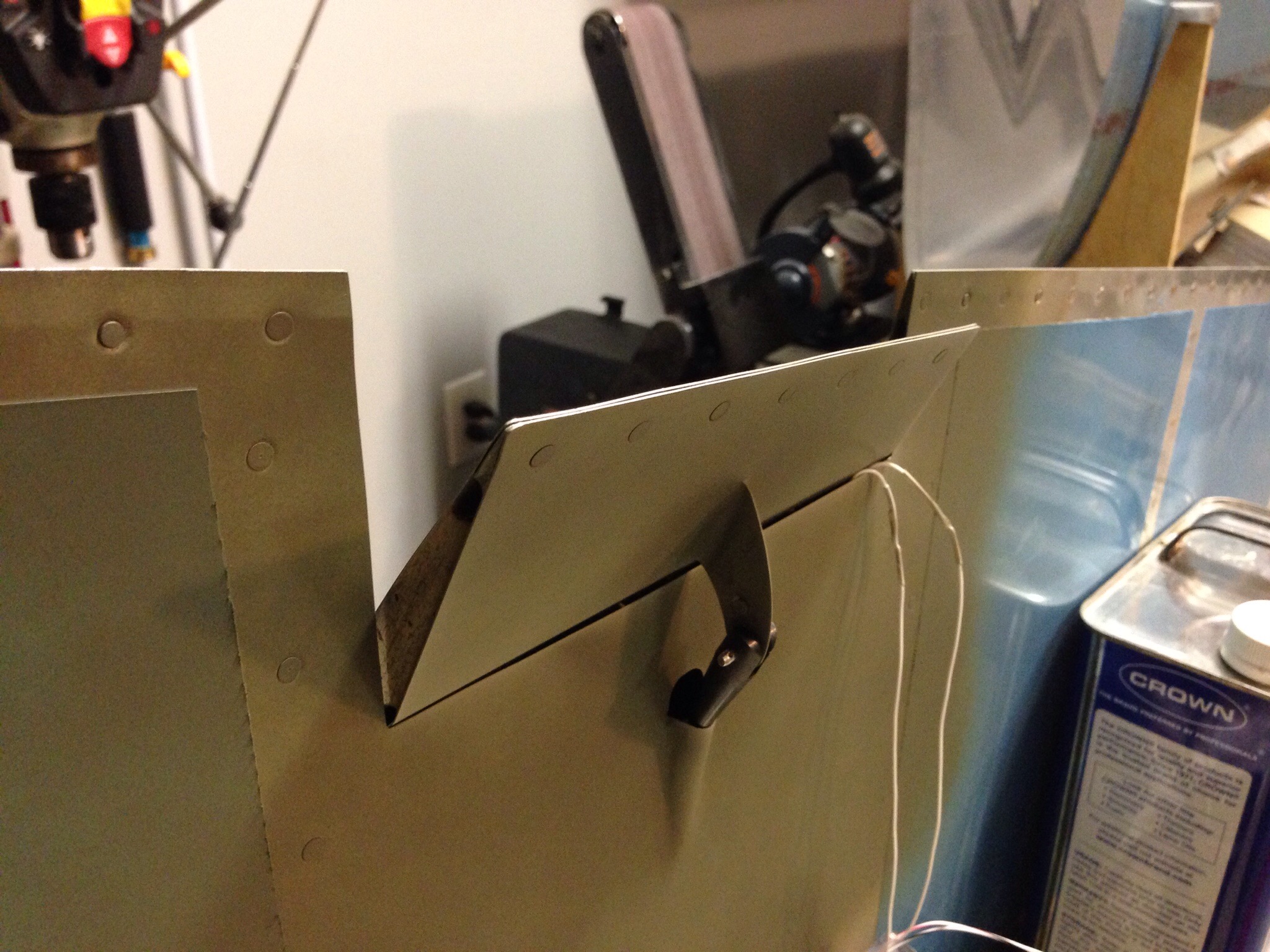

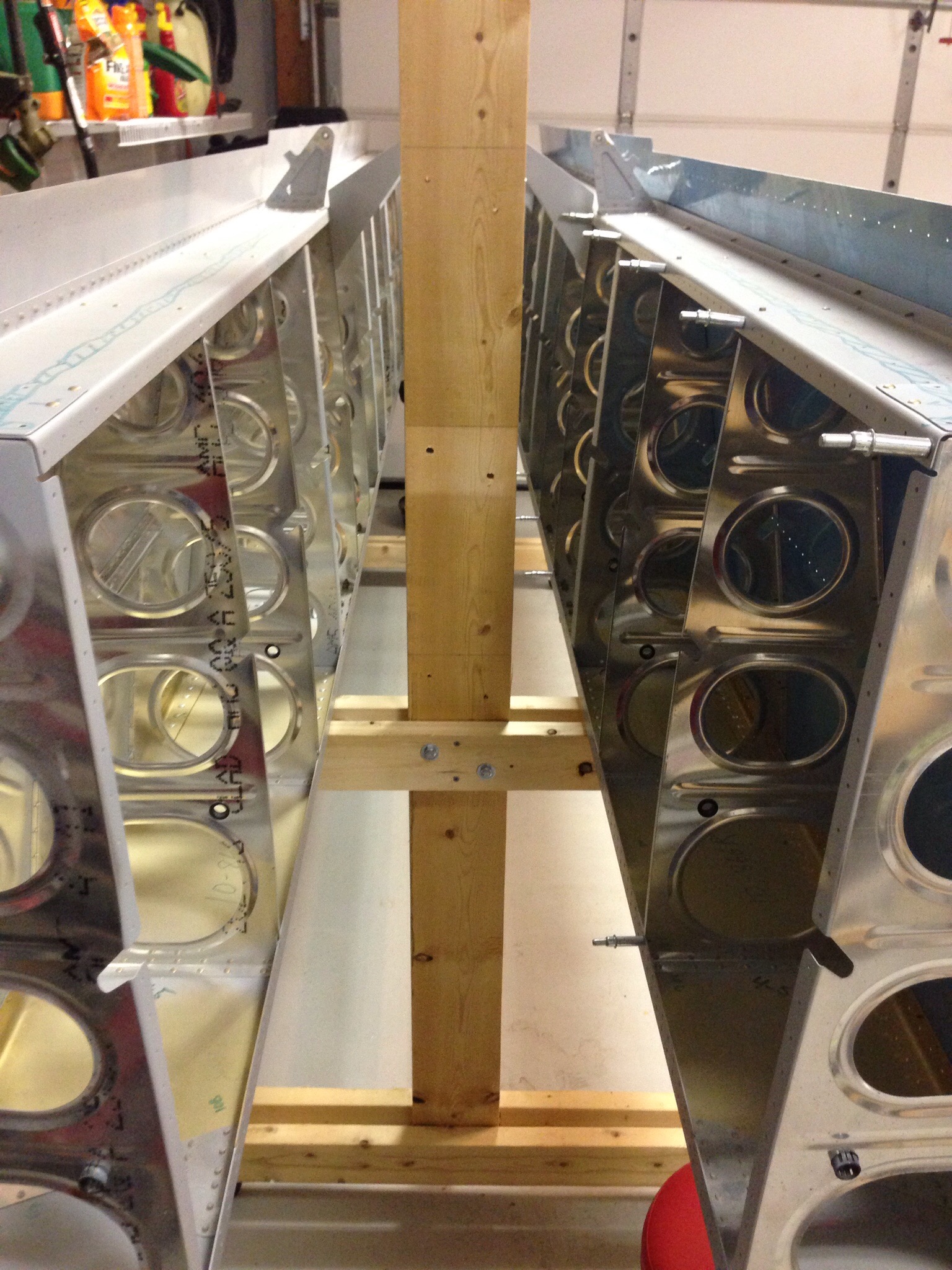

The right tank wasn’t done fighting. The one rivet on the fuel cap flange continued to drip like I hadn’t even attempted to fix it. And the rather large leak on the front spar continued to leak, albeit a bit slower and farther out on the spar proving I didn’t really fix it but just slowed the exit path. So, again it was drained of 30 gallons of water down the driveway and dried out to prep another fix session. For now, here is the completed bits of the left wing.

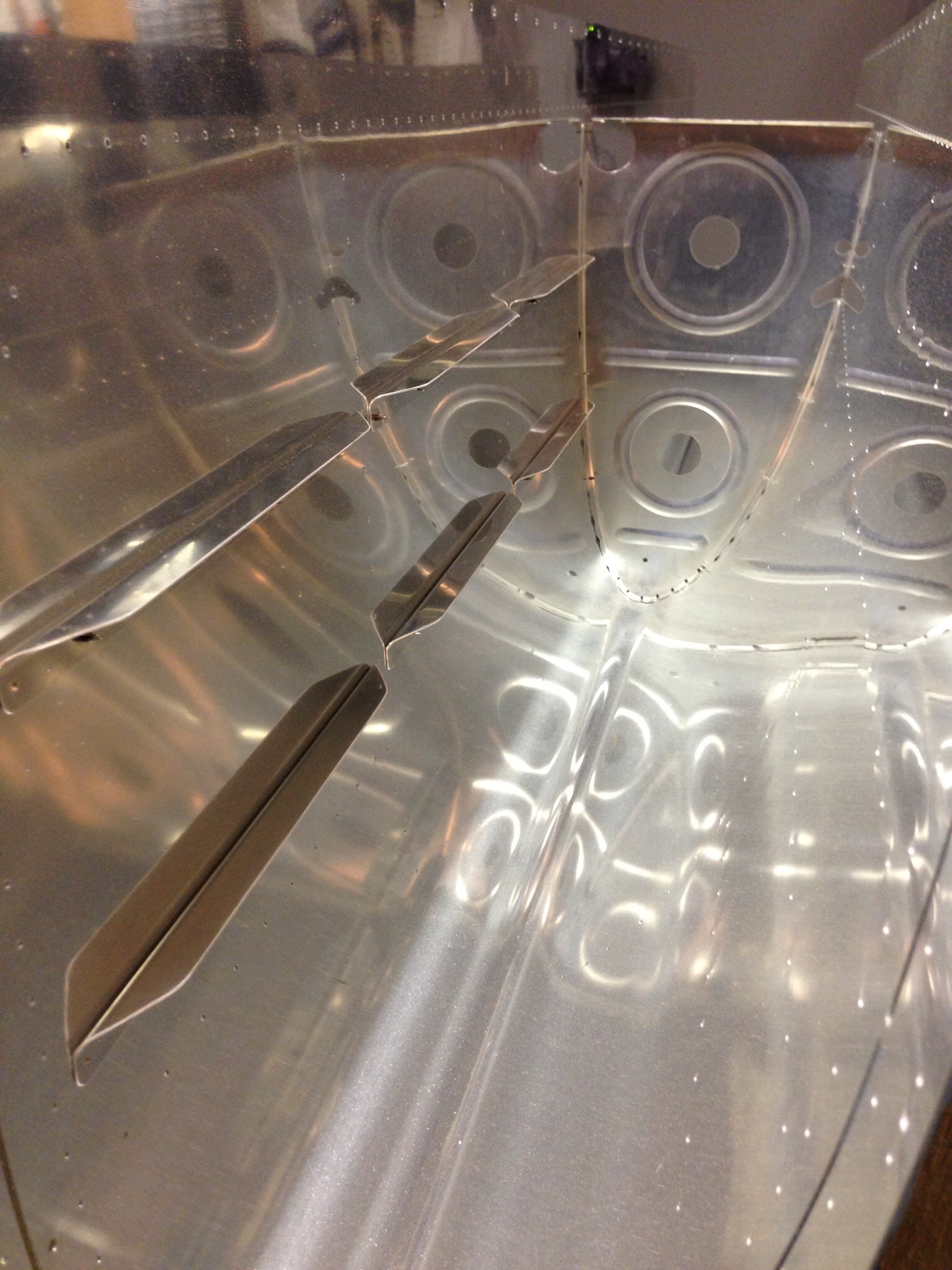

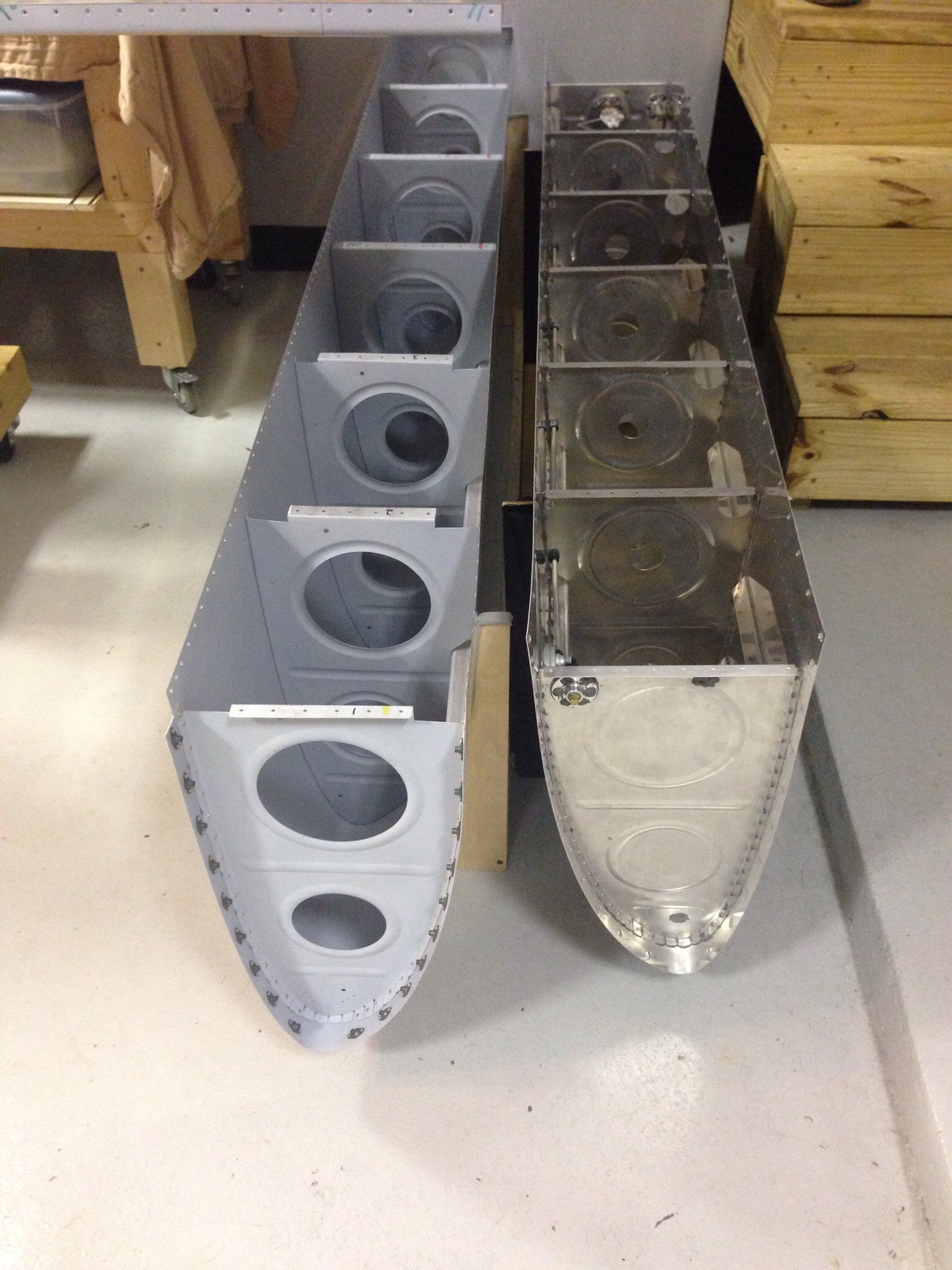

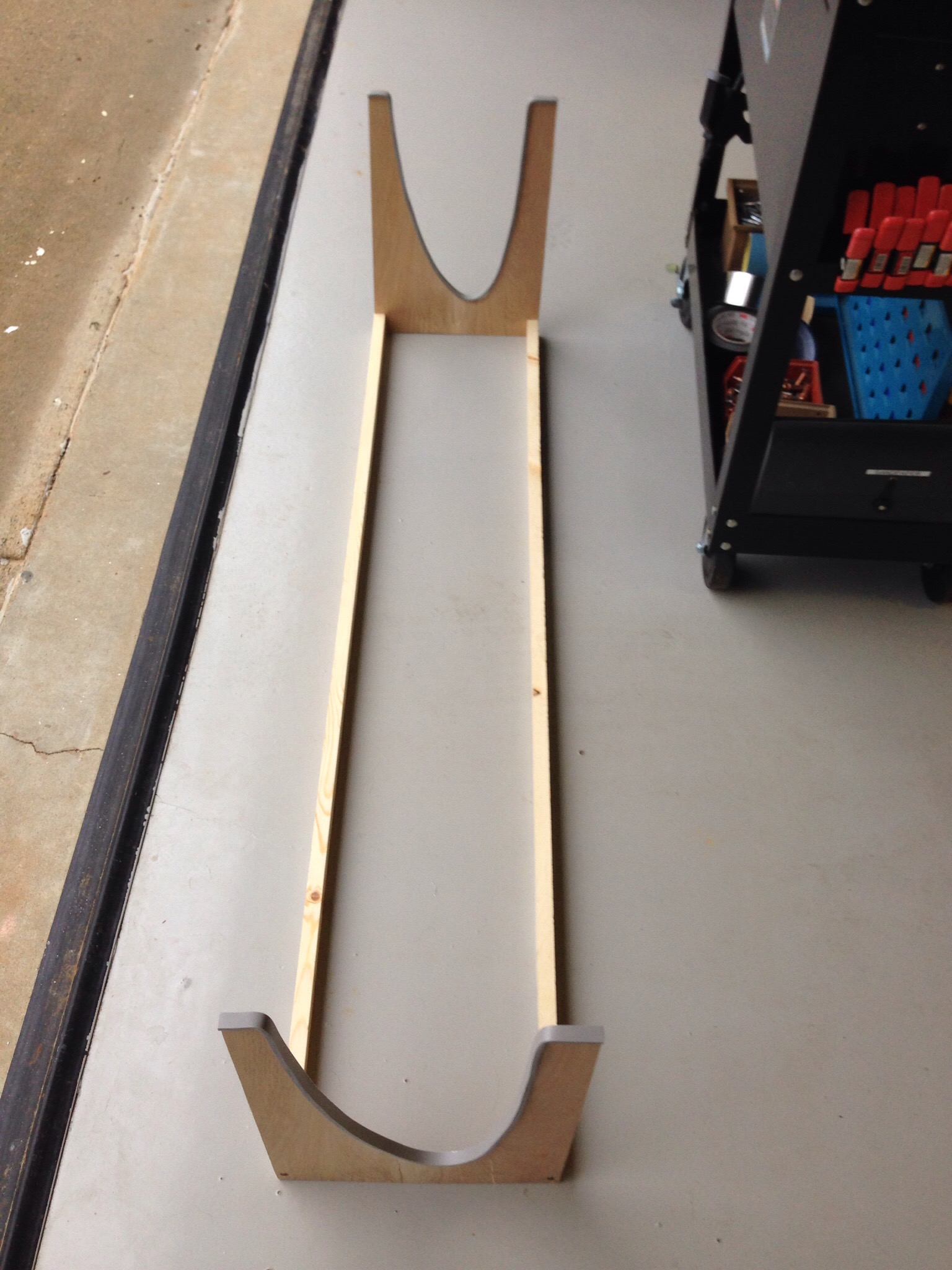

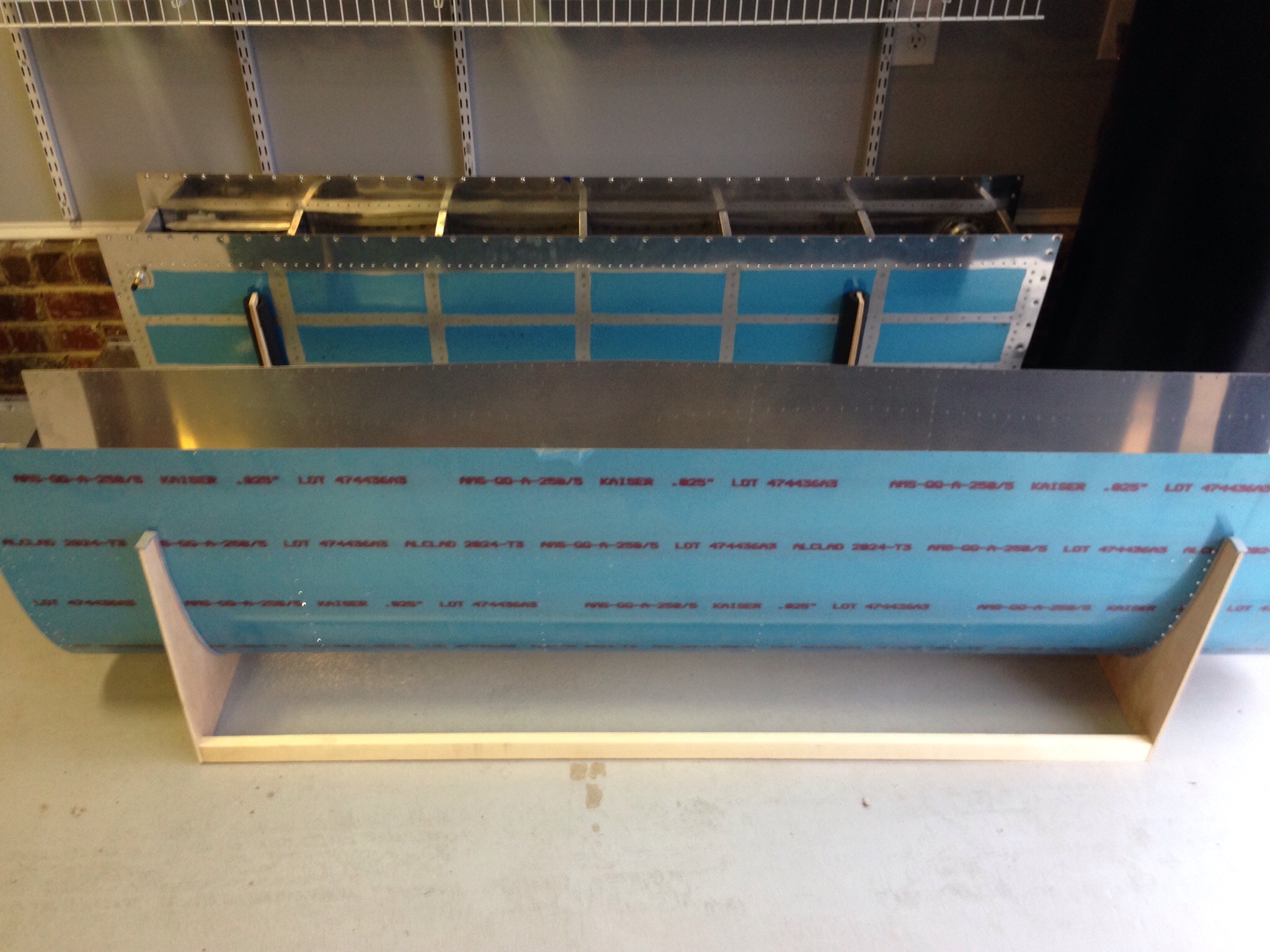

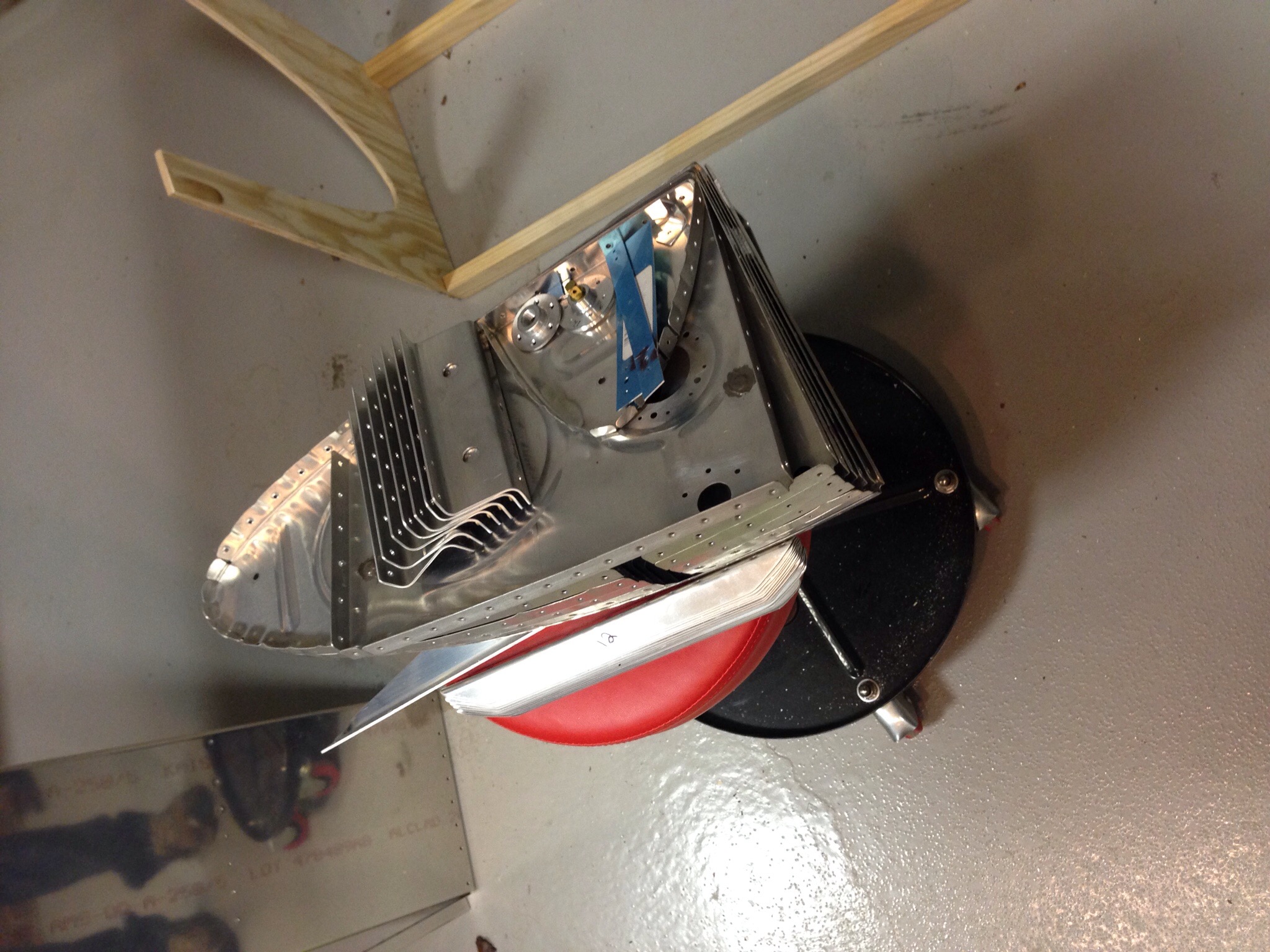

It’s hard to believe that almost all the components of the fuel tank can fit on my little stool. I scuffed the joint surfaces to promote adhesion for the Pro Seal on all the parts. These are all set for final installation into the skin.

It’s hard to believe that almost all the components of the fuel tank can fit on my little stool. I scuffed the joint surfaces to promote adhesion for the Pro Seal on all the parts. These are all set for final installation into the skin. This is where things can get sticky. The biggest advice I read was to be prepared for working with Pro Seal and to wear two pairs of gloves while replacing the outer pair often. Once Pro Seal touches a surface, it doesn’t come off without MEK. I used a postage scale to weigh the components, ceramic tile to mix, and the applicator gun from Brown Tool. All that equaled a clean, easy process of using Pro Seal.

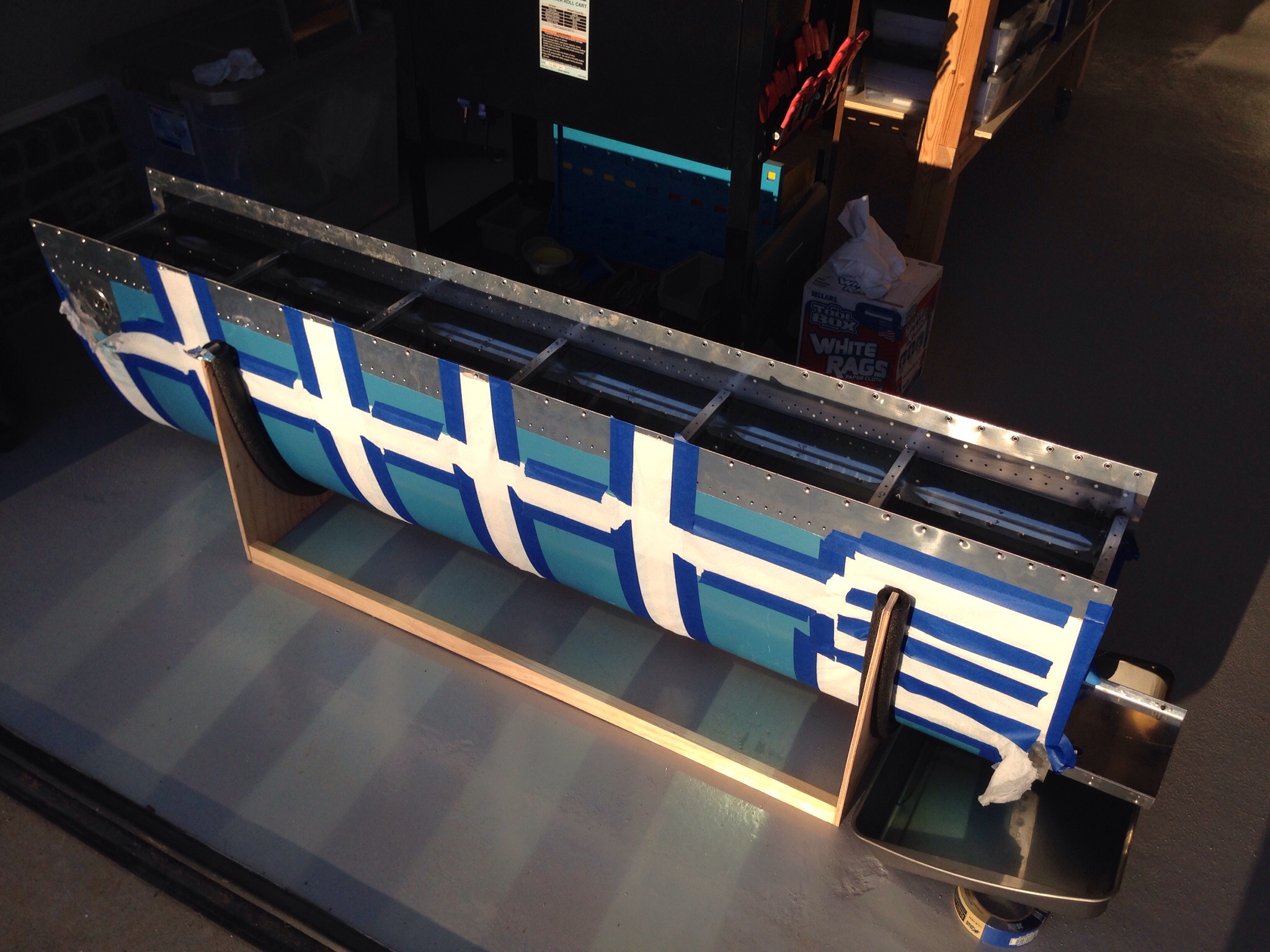

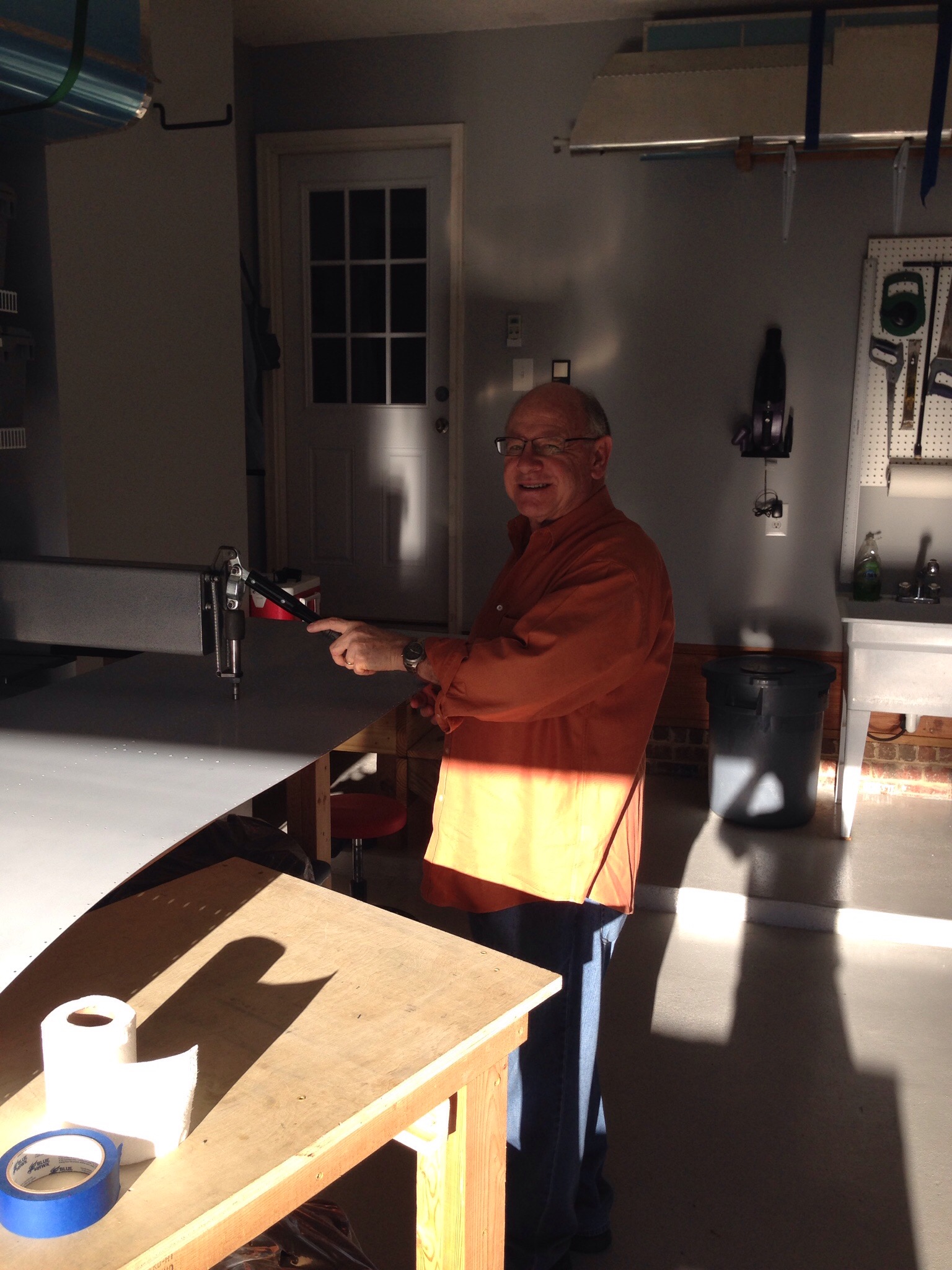

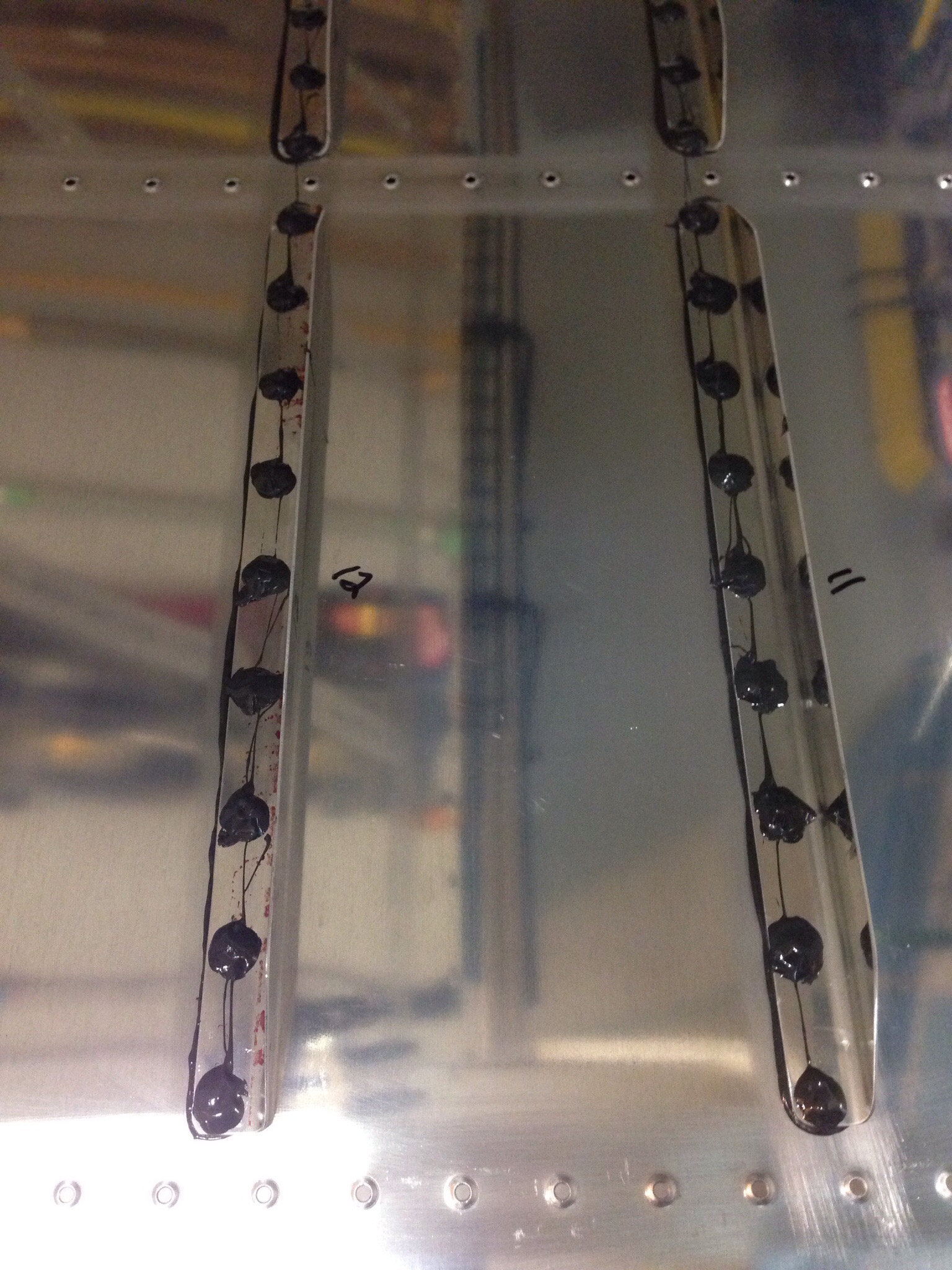

This is where things can get sticky. The biggest advice I read was to be prepared for working with Pro Seal and to wear two pairs of gloves while replacing the outer pair often. Once Pro Seal touches a surface, it doesn’t come off without MEK. I used a postage scale to weigh the components, ceramic tile to mix, and the applicator gun from Brown Tool. All that equaled a clean, easy process of using Pro Seal. The wife-copilot-cobuilder-photographer came out to help and we started with the stiffeners. I chose to 100% cleco the parts in place and come back for riveting the next day. It greatly reduces the mess and actually makes riveting easier. Kayla the flight engineer dog came out to support the project as well. The next day, I came out to rivet the stiffeners with a dab of Pro Seal in each dimple to seal the mfr head of the rivets. Turned out well with the tank die dimple, as it’s a nice flush surface.

The wife-copilot-cobuilder-photographer came out to help and we started with the stiffeners. I chose to 100% cleco the parts in place and come back for riveting the next day. It greatly reduces the mess and actually makes riveting easier. Kayla the flight engineer dog came out to support the project as well. The next day, I came out to rivet the stiffeners with a dab of Pro Seal in each dimple to seal the mfr head of the rivets. Turned out well with the tank die dimple, as it’s a nice flush surface.

I went solo and finished up the ribs and the j-stiffener for each tank after mixing up yet more sticky stuff. I found that letting the sealant cure for one day was perfect for riveting, so the following day was spent riveting the ribs and j channel. I also went back and put a blob of sealant on each shop head, completely sealing each rivet (hopefully) to prevent any fuel seepage.

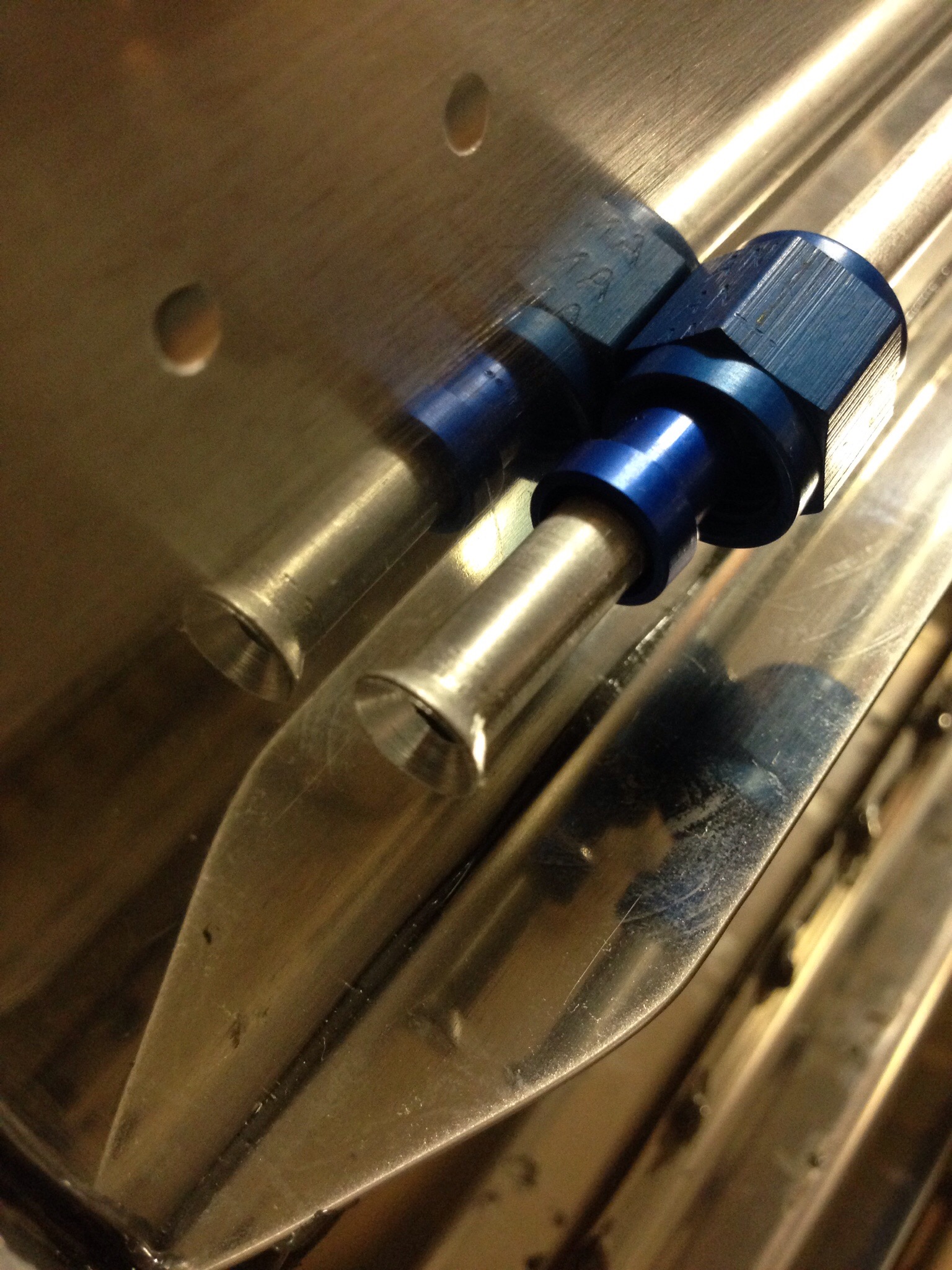

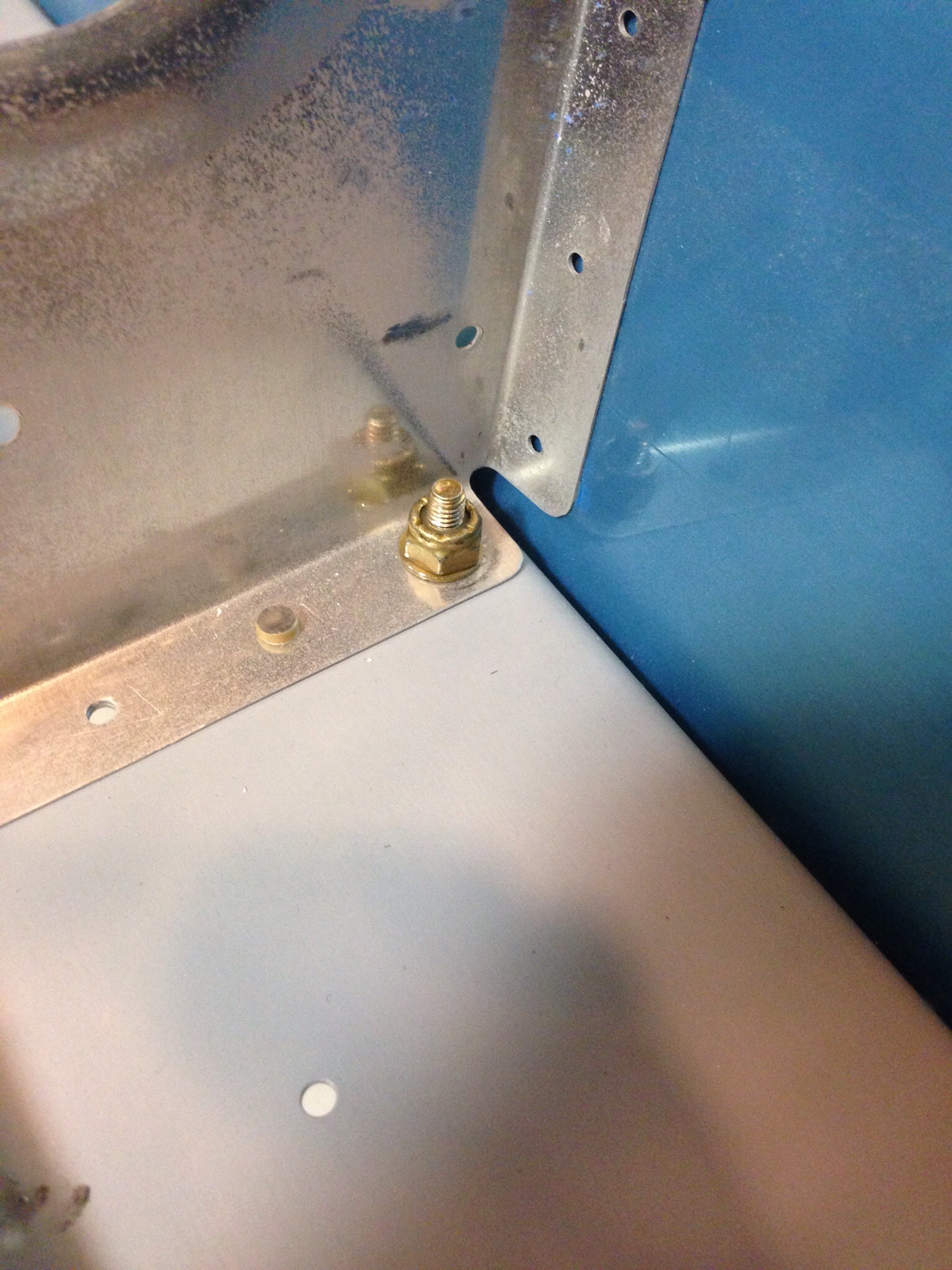

I went solo and finished up the ribs and the j-stiffener for each tank after mixing up yet more sticky stuff. I found that letting the sealant cure for one day was perfect for riveting, so the following day was spent riveting the ribs and j channel. I also went back and put a blob of sealant on each shop head, completely sealing each rivet (hopefully) to prevent any fuel seepage. The next step is to fabricate the fuel vent lines, which consists of straightening very carefully the aluminum tubing and flaring one end to accept the AN fitting through the end rib. I skipped ahead on the plans and riveted the end rib on before putting the line in, but was able to easily work around it. None the less, it’s a good lesson to stick to the plans. Pro Seal is permanent, so no going back and redoing!

The next step is to fabricate the fuel vent lines, which consists of straightening very carefully the aluminum tubing and flaring one end to accept the AN fitting through the end rib. I skipped ahead on the plans and riveted the end rib on before putting the line in, but was able to easily work around it. None the less, it’s a good lesson to stick to the plans. Pro Seal is permanent, so no going back and redoing!