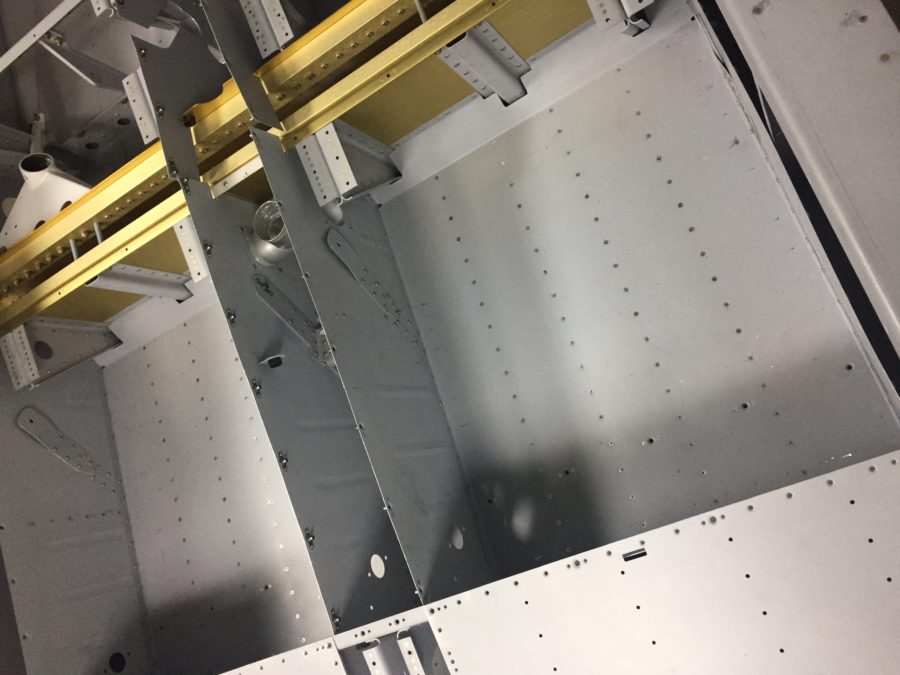

One section that I skipped over is the forward fuselage / instrument panel section. This needs to be done before the cabin top goes on, but is left off while working on the firewall area and rudder pedals. I had all the parts down so wanted to get the assembly together and out of the way. Part of the fabrication steps require the use of the stock panel blank, which I don’t have since I’m using the Aerosport panel down the road. Fortunately, Parish had the blank and I was able to borrow it to complete the related steps. I paid him back by fabricating the two curved supports. The plans call for using fluting pliers, but there is no way that was going to happen. Fortunately the sheet metal shop on base has some great tools and even better craftsmen that were willing to help out in exchange for a few adult beverages. All four pieces turned out beautiful and matched up perfectly. It really is all about having (access to) the right tools!

Once all the parts were prepped and primed, assembly was frustrating as the AN470 rivets are difficult to buck in thin metal. I just have bad luck / technique when trying to hit these on thin structures. One or two drilled out and replaced after a few deep breaths and it was ready to go back into storage. This will most likely be modified once I have the panel and some avionics depending on location and dimensions of the components.

Once all the parts were prepped and primed, assembly was frustrating as the AN470 rivets are difficult to buck in thin metal. I just have bad luck / technique when trying to hit these on thin structures. One or two drilled out and replaced after a few deep breaths and it was ready to go back into storage. This will most likely be modified once I have the panel and some avionics depending on location and dimensions of the components.