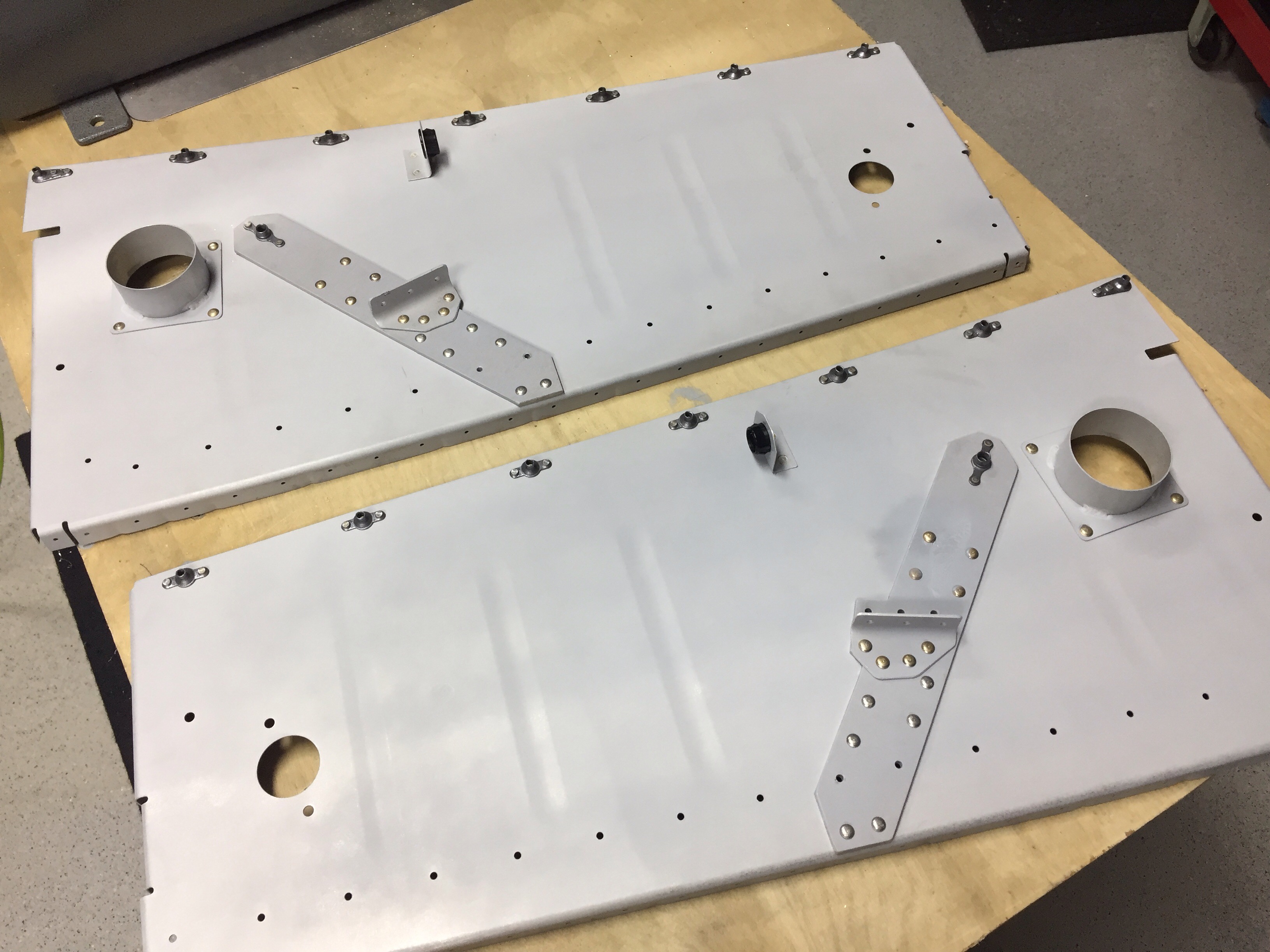

Once the bulkheads are all together, there is an infinite amount of ribs that are attached making up the bottom of the fuselage. It’s also where the pilot and passengers park their butts, so it’s pretty important to get right. Fortunately, I’m really good at drilling out rivets. More on that in a minute.

The ribs take a lot of work to prep, as they are very closely spaced and there’s a lot to scuff and prime. The prepping alone took a few hours and got a bit boring. It was also a bit tricky making sure I had everything in the right spot. Attention to detail on the plans was important and I had to reference a few future sections to see what the bigger picture is on where stuff goes.

Finally everything is primed and now it’s time to rivet. I just can’t get into a groove with my offset rivet set. I am drilling out about a fifth of the rivets because I am smashing the manufactured head. I also riveted an outside rib on without putting the other end of it inside a bulkhead, so all of those rivets had to come out. I had to slow myself down and refocus which is yielding better results.

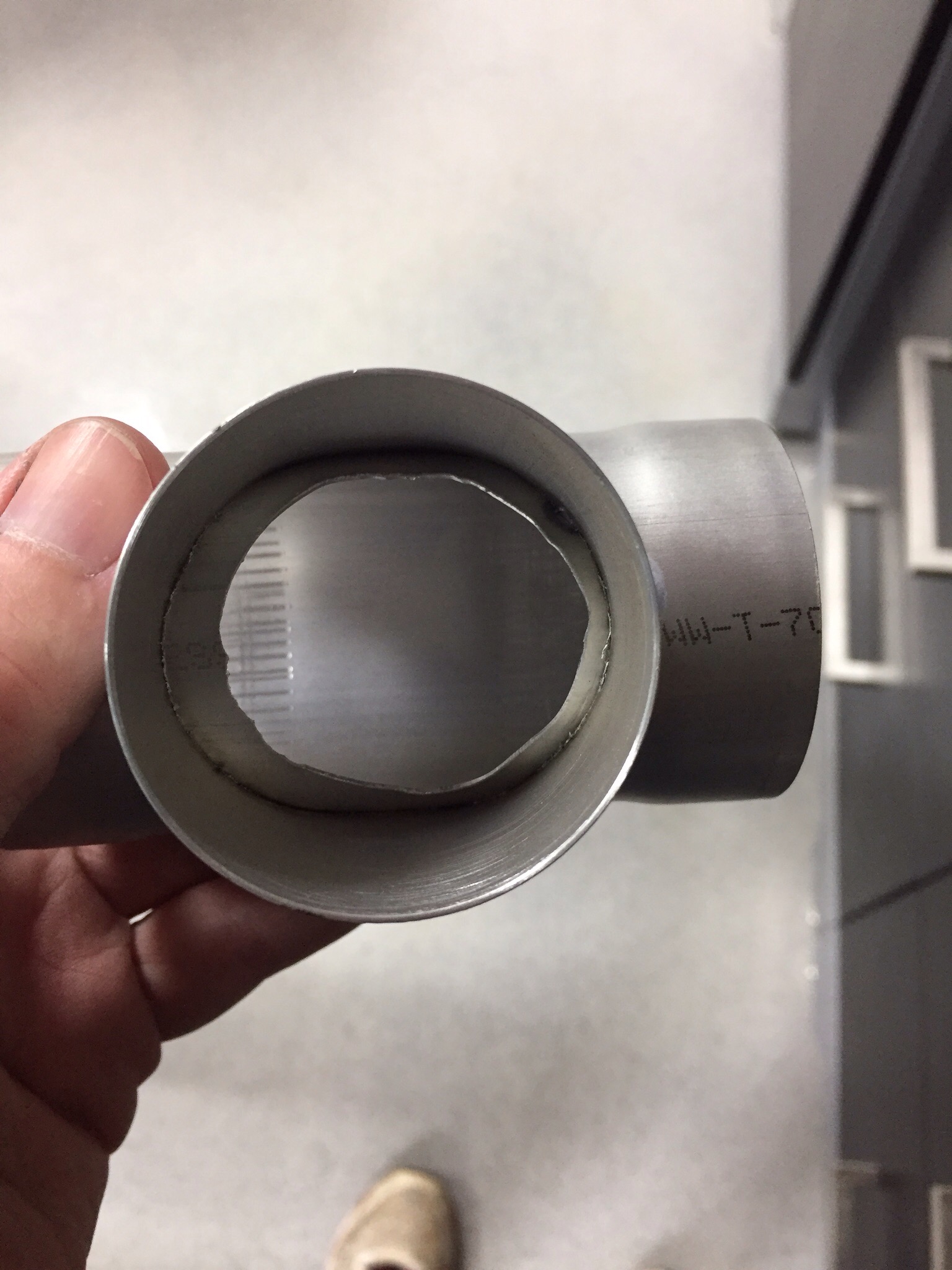

I did take some time to clean up the heat duct tee before installing. I’m sure there is plenty of heat in the back, but why leave an ugly piece in the project when I could fix it up. Before and after shows a nice increase in the outlet area so it should provide smoother airflow compared to the original condition.