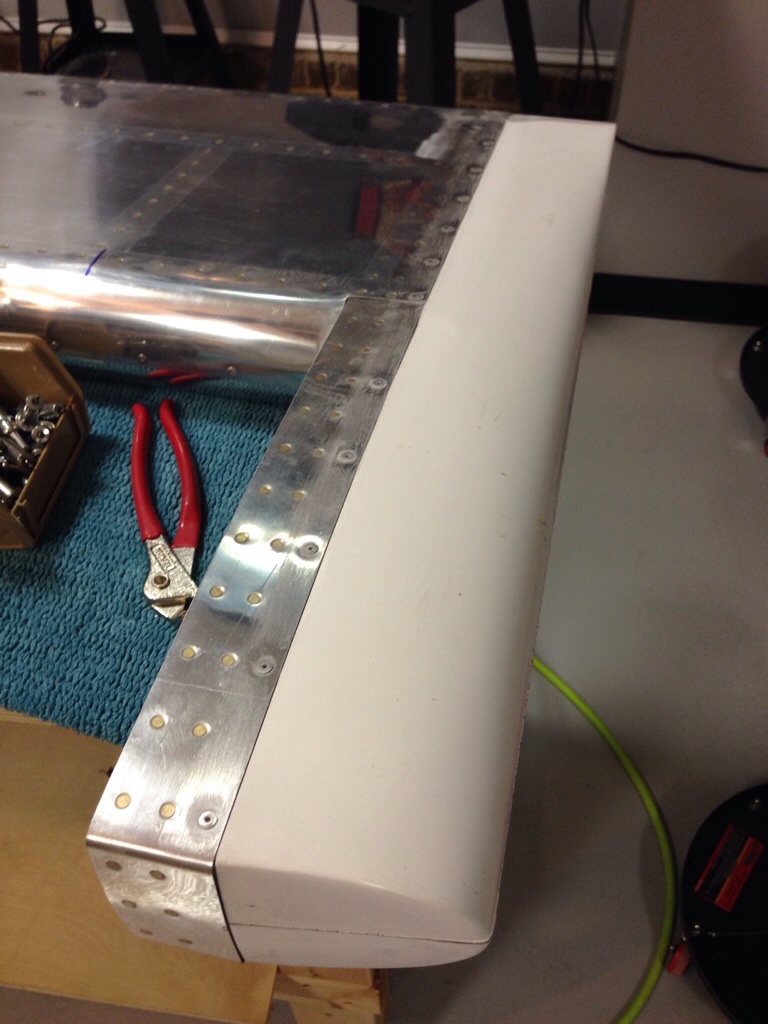

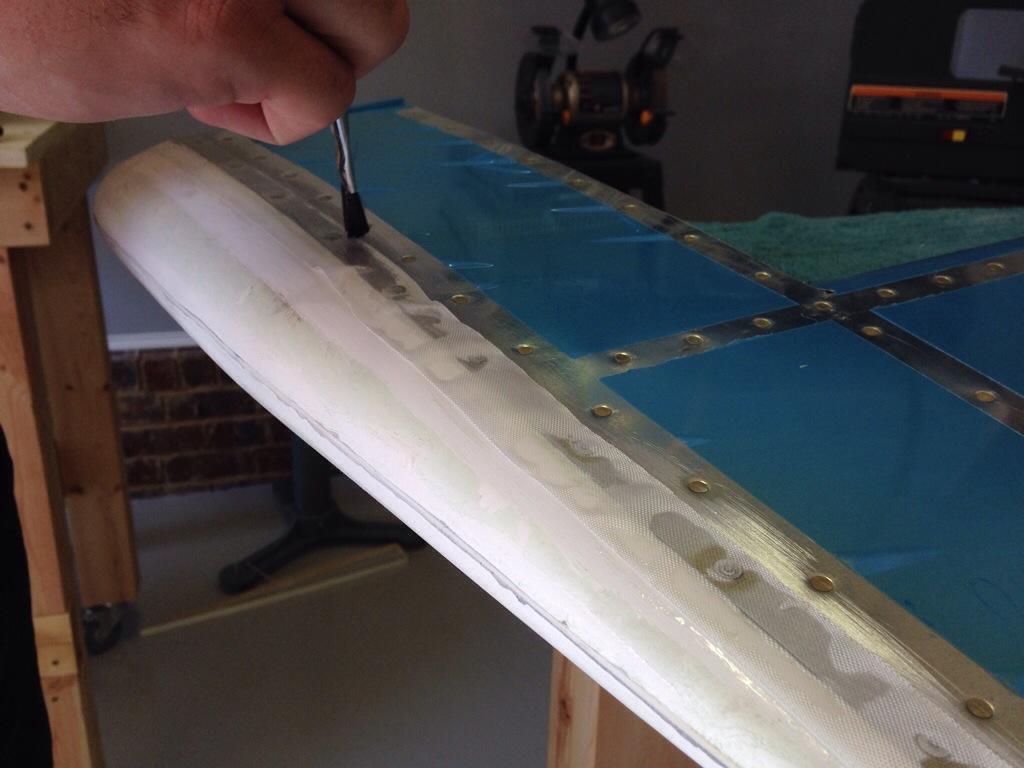

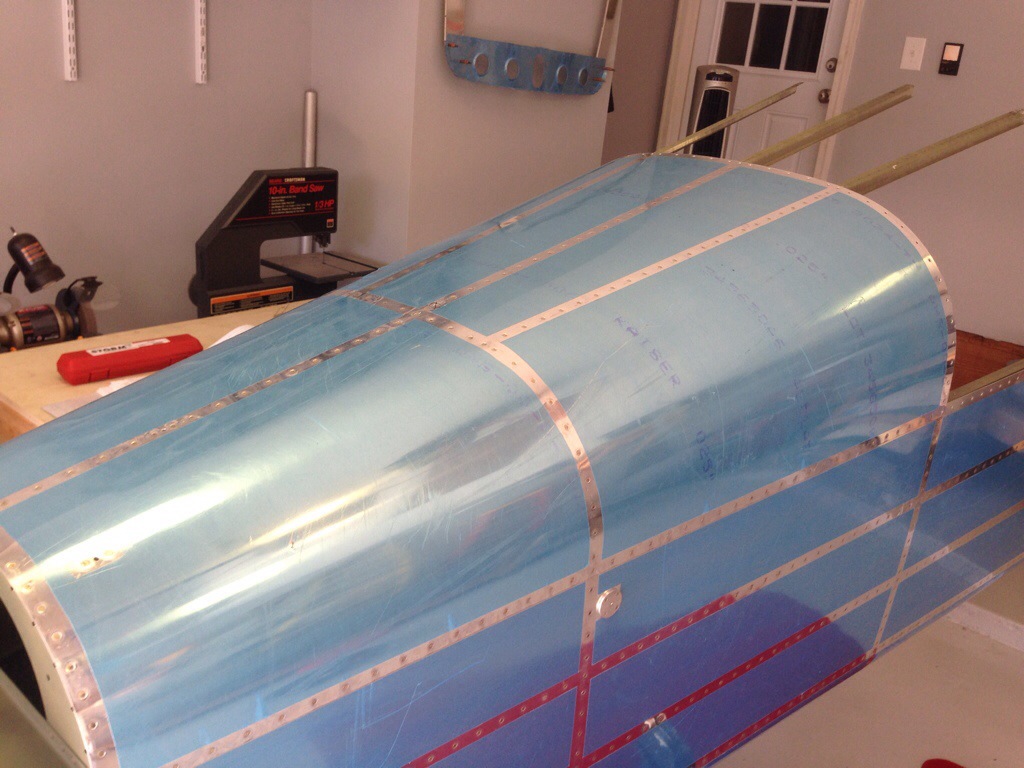

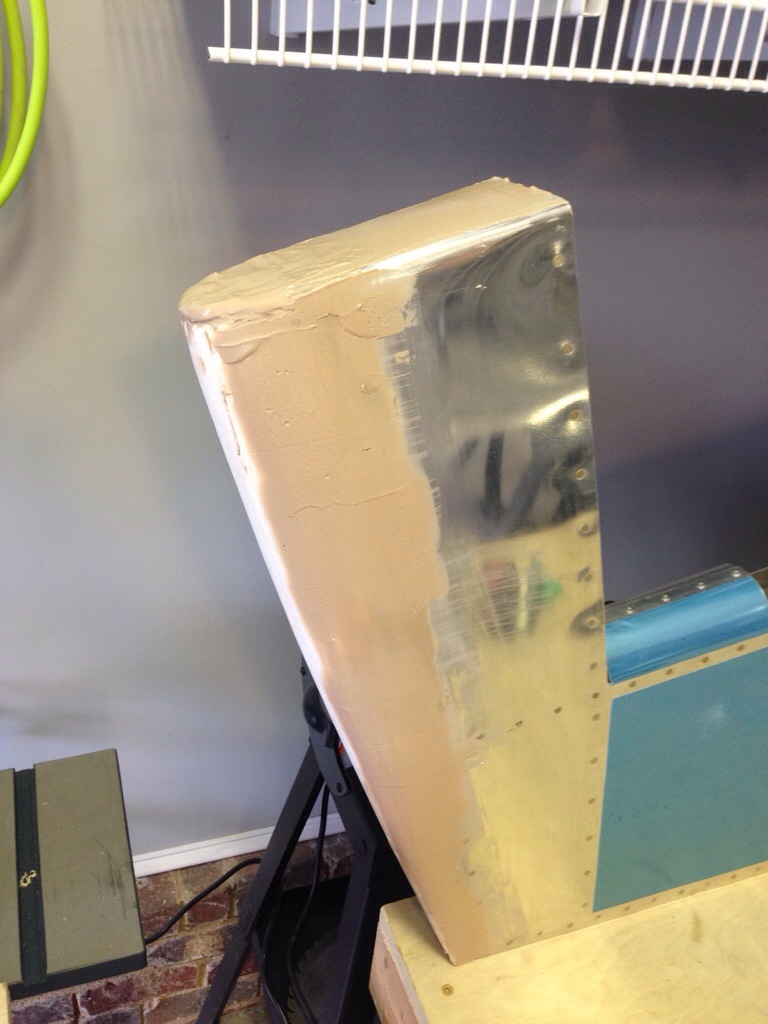

After the epoxy set up on the fiberglass tips, it was time to put on the filler, often referred to as micro, to smooth things out. I’m using the West epoxy system and the 407 filler. It’s an extremely fine powder that is a tan color and according to others very easy to work with. You mix up the epoxy as normal with a 5:1 ratio and then add in the filler to get a consistency of creamy peanut butter. Then just spread it on and smooth it out as best you can then wait for it to cure.

I’m not a stranger to using Bondo, dry wall mud, and other fillers, but I still have a few lessons learned from my first experience on the plane. First is when mixing the filler, you want a really think peanut butter mix, not creamy. My first batch ran and settled a little too much, requring me to position the pieces so it wouldn’t drip. Keep in mind it takes a few hours for the slow hardener to set up. If you have a lot to add to build up, make it as dry as you can. Second, follow Ron Propeil’s advice and set it and forget it. Just like dryway, the more you mess with it, the worse it gets. You won’t get a perfectly smooth application so stop trying. That’s what sand paper is for! Third, is patience which I do actually have for this. One coat is seldom enough to smooth out whatever your working on. Go in stages and don’t try to build Rome in a day.

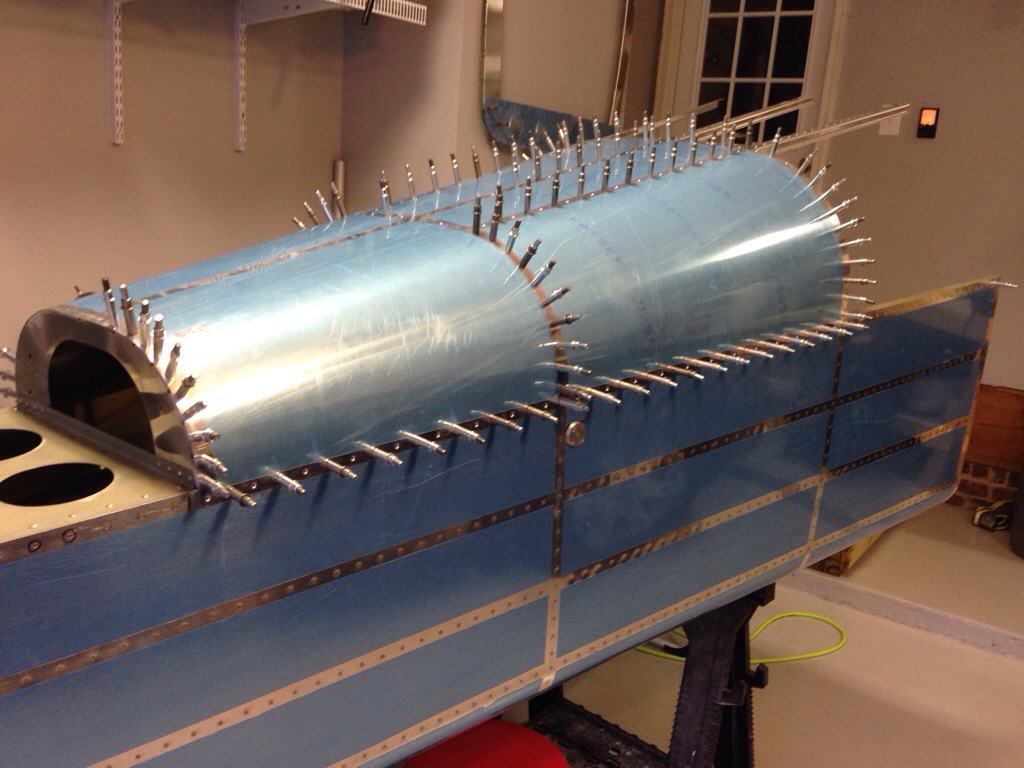

Thus, my first coat was pretty successful. I scuffed up the newly laid fiber and made sure the aluminum was scuffed with a Scotchbrite pad. Then clean everything with thinner and apply the filler. I filled in a lot on the tips’ leading edge where it didn’t match up with the aluminum well. I was also excited that it actually set up well! I have a fear of mixing the epoxy wrong and it just being a goopy mess. The pump system for the West epoxy is a must have.

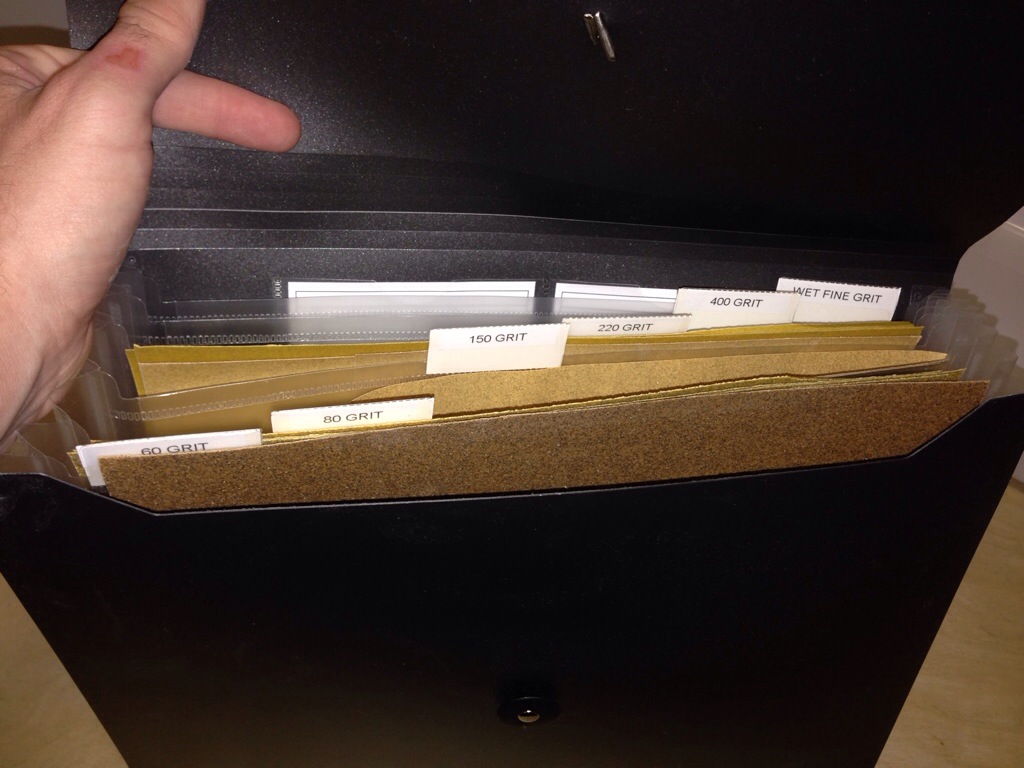

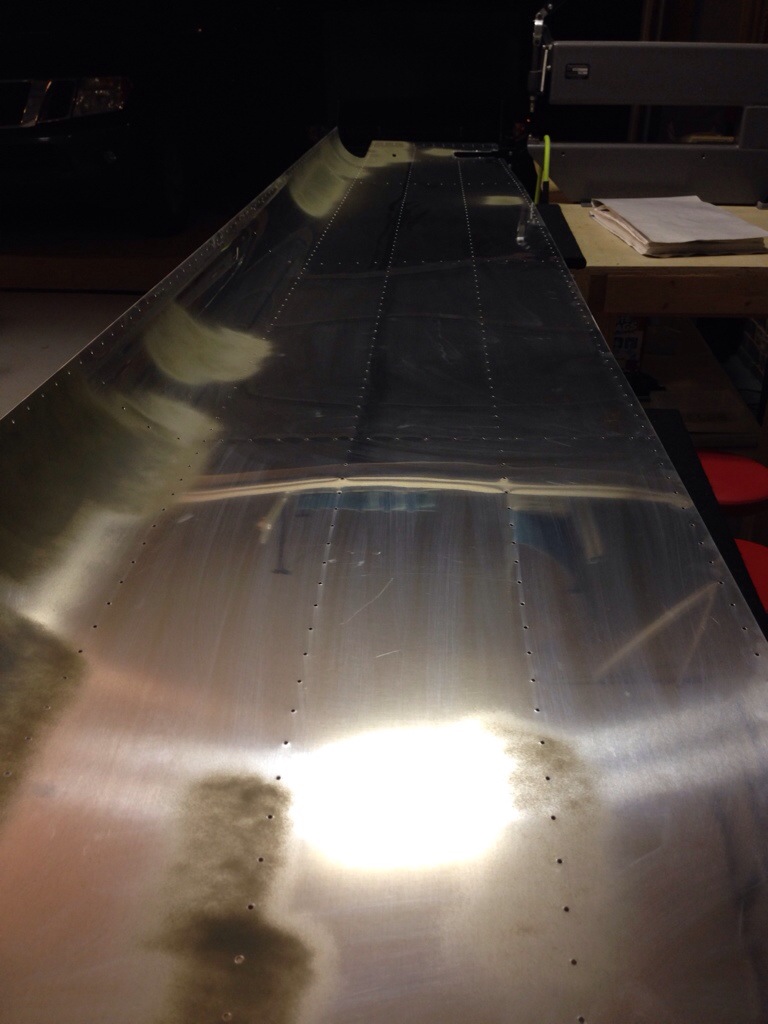

Next, you get to break out the sand paper. And a lot of it. A couple lessons on this too. Have a variety of grits; I used 80 to knock off the big ridges and bumps, then 150 to contour, and 220 to smooth it all out. I found that the 150 really didn’t work too well as the dust would bond to the paper and clog it up. The 220 worked great and lasted a long time. I have a couple of different blocks that are working well. I’ve read never to use your fingers since they will not sand uniformly, but there are always a few spots that the block can’t get. Make sure not to sand too much off. It’s better to get it close and put another thin layer of filler on to really smooth it out.

I put the second coat on a bit dryer than the first and that was good for the big spots, but also harder to get a smooth application. For the finish coat, it’s better to have it a bit creamier so it will apply smoothly with no pinholes. The second coat was sanded with 80 and then 220. You can tell if you have low spots by the different color when sanding which is nice. Never sand out a low spot. Add to it then smooth it out. Blow off the dust, clean with thinner, and repeat the application process. This is the third coat and I’m pretty sure it will be enough. The corners are still hard so I gooped it on and will sand it smooth. I’m hoping the other side will go faster since I’ve got some experience under my belt. I’ll finish it all with a 440 grit before doing some quick primer and reevaluating.

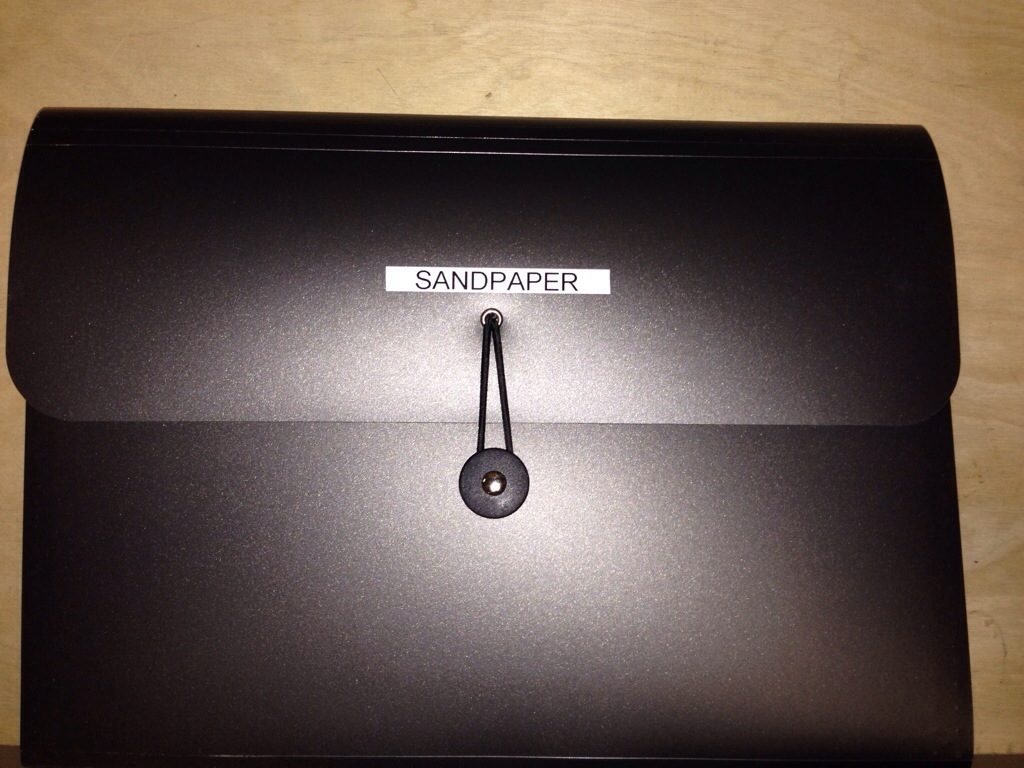

And of course, you have to have things organized. So to keep all this sand paper (I have more than listed), I got a cheap expanding folio at Wal-Mart Aviation Supply and threw some labels on it. This works perfect and keeps it all in one spot.