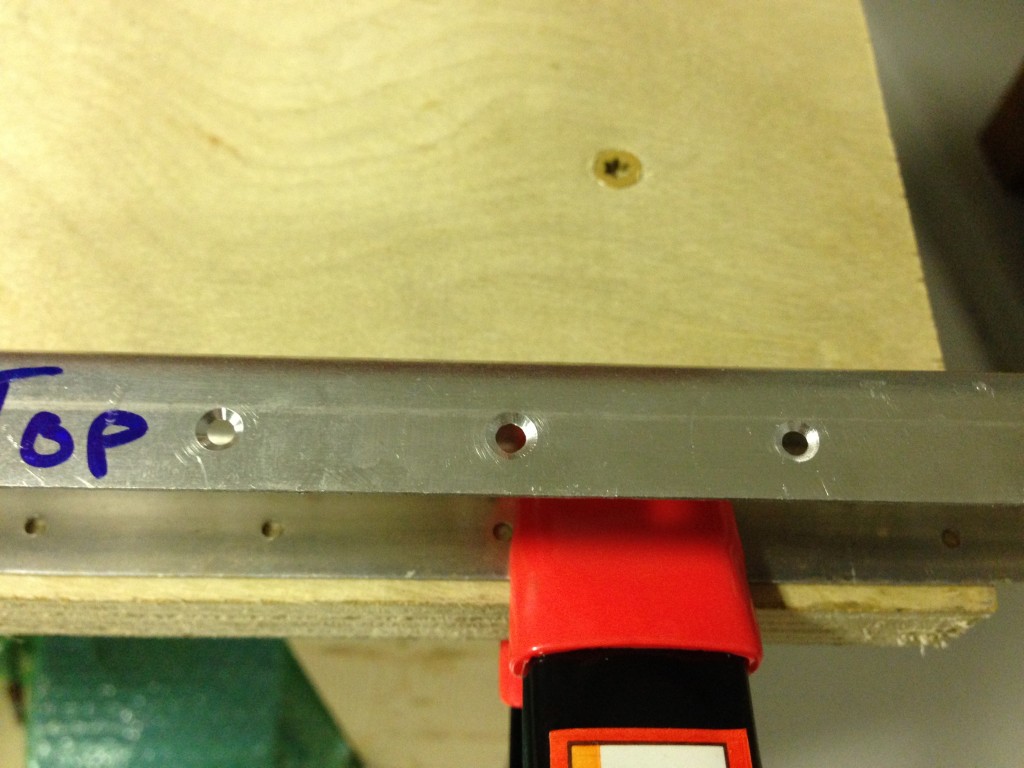

It’s fun when you start to make structural progress! Tonight, I began attaching the small misc. brackets to the main spars for the elevators and also started on the ribs. I first modified one of my workbenches to hold my back-riveting plate flush with the table (check out the Workbench page for details) to make back riveting a bit easier. I’m very happy with the results and got the idea from the previous kit owner who had a large workbench with the same modification.

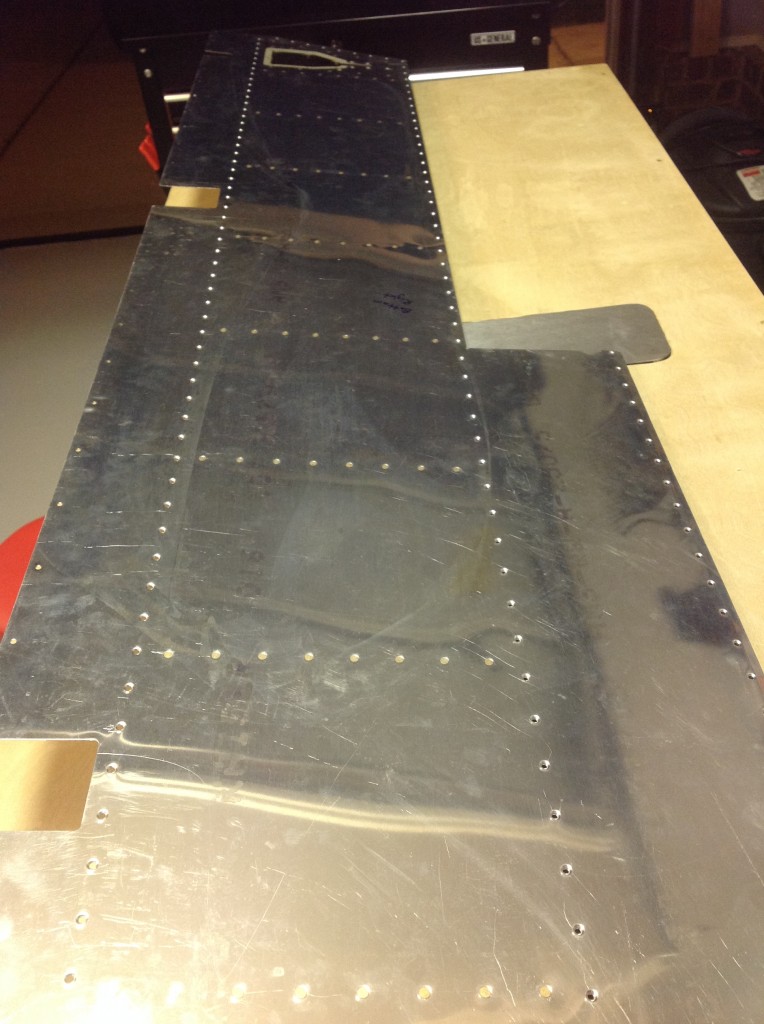

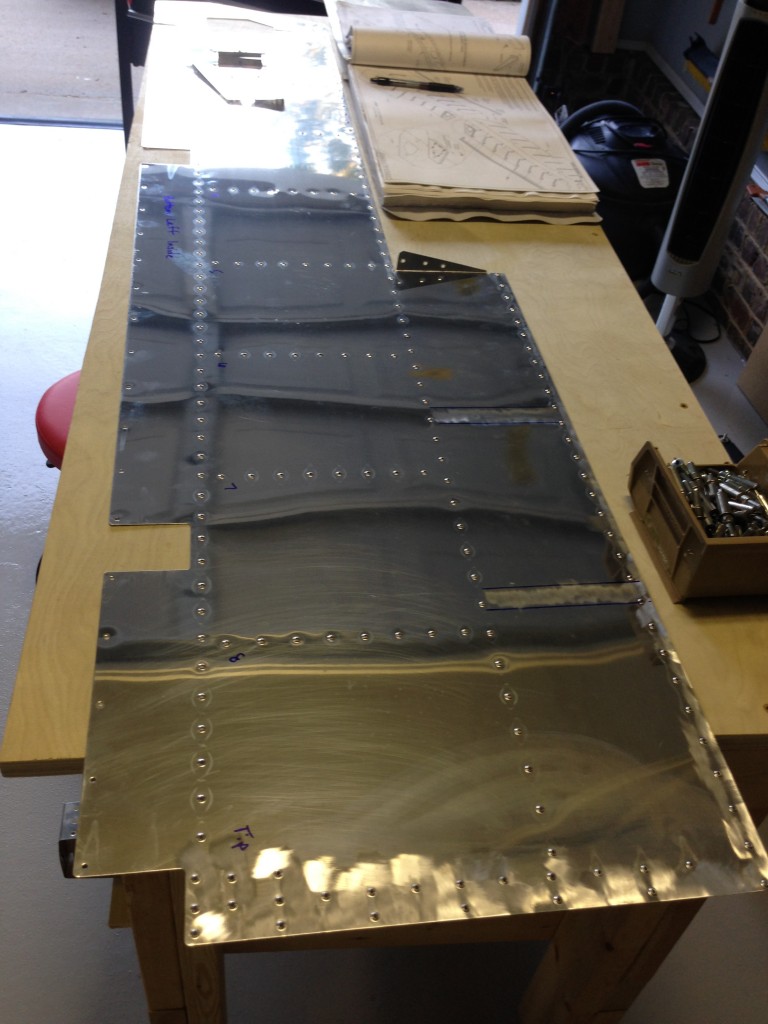

Half the ribs are attached to the skins then they are brought together once the skins are on the spars. I cleaned the pieces well with lacquer thinner and did a final inspection on all pieces for corrosion, as I had just a few small spots on the spars and skins. I spot primed one trim access plate but all else were fine.

Pulled out another supply for the first time, the back riveting head for my rivet gun along with rivet tape. I really like the back riveting, it’s even better than squeezing! I’m really dialing in my air pressure and have found that 55-60 works perfect for a nice firm hit and consistent result to match the rivet size guides. I also quickly discovered that one piece of rivet tape can be used multiple times, so no reason to go through an entire roll on one skin.

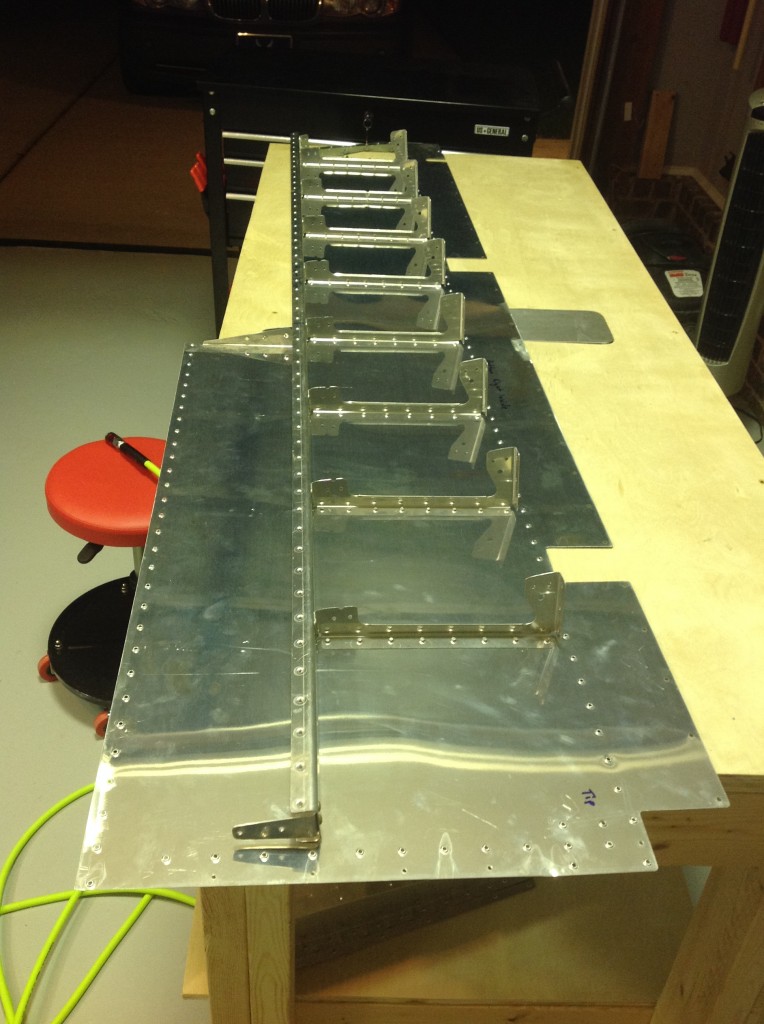

Once the ribs are on the bottom skin, the rear spar is attached to the ribs and later the skins. It was a bit tricky still trying to figure out the die head combination needed to get at all the rivets, but everything went smoothly and I only drilled out one flush rivet the whole evening!

Spent some time working on the website as well to update the garage, tools, and links page. The website is almost more work than the airplane!